Disclosure

This website is a participant in the Amazon Services LLC Associates Program,

an affiliate advertising program designed to provide a means for us to earn fees

by linking to Amazon.com and affiliated sites.

Battery voltage isn’t a one-size-fits-all concept—it varies by type, chemistry, and application. You might assume all AA batteries are identical, but their voltages can differ drastically between alkaline, lithium, or rechargeable variants.

Whether you’re troubleshooting a dead remote, upgrading a solar power system, or building a DIY project, understanding standard voltages is critical to avoiding damage or inefficiency.

Best Batteries for Reliable Voltage Performance

Energizer Ultimate Lithium AA Batteries

These 1.5V lithium AA batteries outperform alkaline counterparts with a 20-year shelf life, consistent voltage output, and superior performance in extreme temperatures (-40°F to 140°F). Ideal for high-drain devices like cameras and medical equipment, they’re leak-proof and lightweight.

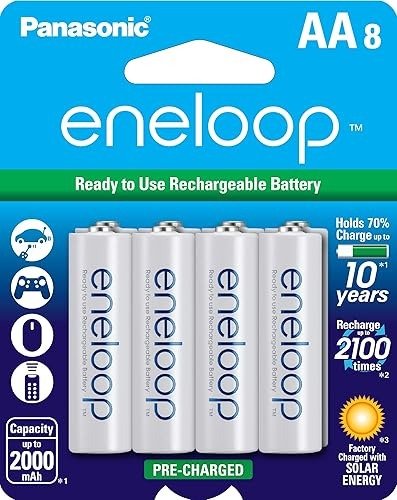

Panasonic Eneloop Pro AA Rechargeable Batteries

With a nominal 1.2V output, these NiMH batteries maintain stable voltage over 500 recharge cycles. Pre-charged with solar energy, they’re perfect for eco-conscious users powering gaming controllers or flashlights. Includes a 2550mAh capacity for extended runtime.

AFSONGOO 18650 Li-ion Battery (3.7V, 3400mAh)

A trusted choice for vaping mods and flashlights, this 3.7V battery features built-in protection against overcharging and short circuits. Its high energy density ensures long-lasting power, while the consistent discharge rate prevents voltage drops during heavy use.

Battery Voltage: The Basics

Voltage, measured in volts (V), represents the electrical potential difference between a battery’s positive and negative terminals. It determines how much energy a battery can deliver to a device. Here’s what you need to know:

1. Primary vs. Rechargeable Batteries

Primary batteries (single-use) like alkaline or zinc-carbon cells have fixed voltages that drop as they deplete. For example:

- Alkaline AA/AAA: 1.5V (fresh), dropping to ~0.9V when exhausted

- Lithium coin cells (CR2032): 3V

Rechargeable batteries, such as NiMH or Li-ion, operate at different nominal voltages:

- NiMH AA: 1.2V

- Li-ion (18650): 3.7V (nominal), 4.2V when fully charged

2. Why Voltage Standards Matter

Using the wrong voltage can:

- Damage devices: Overvoltage fries circuits; undervoltage causes malfunctions

- Reduce efficiency: A 1.2V NiMH in a 1.5V-designed toy may underperform

Example: A 9V smoke detector requires exactly 9V—a 7.4V Li-ion pack won’t trigger alarms reliably.

Measuring and Maintaining Voltage

Use a multimeter to check voltage. For rechargeables, monitor charge cycles—Li-ion degrades after ~500 cycles, dropping below 3.2V.

Nominal Voltage vs. Actual Voltage

Battery voltage isn’t static—it fluctuates based on chemistry, load, and charge state. The nominal voltage (e.g., 1.5V for alkaline AA) is an average reference, while actual voltage changes during use. Here’s why this distinction matters:

How Battery Chemistry Affects Voltage

Different battery types maintain voltage differently:

- Alkaline: Starts at ~1.6V when fresh, drops steadily to 0.9V under load. Devices often cut off at 1.2V, leaving unused energy.

- Lithium (Primary): Holds near 1.5V until nearly depleted, making them ideal for precision devices like digital thermometers.

- NiMH: Operates at 1.2V nominal but can peak at 1.4V when fully charged, confusing users expecting 1.5V performance.

Real-World Voltage Behavior

A 9V alkaline battery might read 9.5V off the shelf but drop to 6V under a 500mA load. This voltage sag is why:

- Smoke alarms beep when voltage falls below 7.2V, even if the battery isn’t “dead.”

- LED flashlights dim gradually as voltage decreases, unlike incandescent bulbs that fail abruptly.

Why Load Matters

High-drain devices (e.g., DSLR cameras) pull current faster, causing greater voltage drop. Example:

- A AA alkaline might deliver 1.3V at 100mA but only 1.0V at 1A.

- Rechargeable Li-ion handles high loads better, maintaining 3.6V even at 2A discharge.

Pro Tip: For critical applications, measure voltage under load with a multimeter. A “full” 12V car battery reading 11.8V when starting reveals a weak cell.

How to Measure Battery Voltage Accurately

Proper voltage measurement is crucial for diagnosing battery health and preventing device damage. Unlike simple “full/empty” indicators, professional testing reveals hidden issues like internal resistance or cell imbalance. Here’s how to get reliable readings in different scenarios:

Choosing the Right Tools

Not all multimeters are equal for battery testing:

- Basic models (under $20) often lack precision for low-voltage measurements below 1V

- Auto-ranging meters like the Fluke 101 simplify testing but may miss small voltage drops

- Battery analyzers (e.g., ZTS MBT-1) apply realistic loads to simulate actual device usage

Step-by-Step Measurement Process

- Set your multimeter to DC voltage mode (V⎓) with a range exceeding expected voltage (e.g., 20V scale for 9V batteries)

- Connect probes correctly – red to positive terminal, black to negative, even on button cells where polarity markings may be tiny

- Measure under load by placing a resistor (e.g., 10Ω for AA batteries) across terminals while measuring for 5 seconds

- Interpret results – a 1.5V alkaline reading 1.35V under load has ~50% capacity remaining

Troubleshooting Common Issues

When readings seem off:

- Fluctuating values often indicate poor probe contact – use alligator clips for stability

- “Ghost voltage” in parallel battery packs means testing individual cells is essential

- Sudden voltage drops during measurement reveal high internal resistance (common in old NiMH batteries)

Professional Tip: For rechargeable packs, measure voltage 30 minutes after charging to avoid false high readings from surface charge. Lithium batteries should rest 2 hours for accurate state-of-charge assessment.

Battery Voltage Standards Across Different Applications

Understanding industry-standard voltage ranges helps prevent compatibility issues and optimizes device performance. These standards evolved from both technical requirements and historical conventions, creating distinct voltage ecosystems.

Consumer Electronics Voltage Landscape

| Device Category | Standard Voltage | Special Considerations |

|---|---|---|

| Portable Electronics | 3.7V (Li-ion) | Actual operating range 3.0-4.2V with power management ICs |

| Photography Equipment | 7.2V/7.4V | Often uses two Li-ion cells in series with balancing circuits |

| Medical Devices | 3V (Lithium primary) | Requires stable voltage for 5+ years in pacemakers |

Automotive Voltage Systems

While nominally 12V systems, actual automotive voltages vary significantly:

- Ignition-off: 12.6V (fully charged) to 11.8V (needs charging)

- Engine running: 13.5-14.7V from alternator charging

- Engine cranking: Must stay above 9.6V during cold starts

Modern vehicles use smart alternators that may temporarily drop to 12.8V for fuel efficiency, confusing basic voltage testers.

Industrial Power Systems

High-capacity applications follow different conventions:

- Telecom: 48V DC with -48V grounding for corrosion prevention

- Solar Storage: 24V or 48V battery banks to reduce current losses

- Aviation: 28V DC standard with 115V AC 400Hz auxiliary systems

Why These Standards Matter

Using incorrect voltages can:

- Trigger safety shutdowns in smart devices (e.g., phones rejecting 5.2V chargers)

- Cause premature failure in motor controllers designed for specific voltage windows

- Create regulatory compliance issues for medical/aviation equipment

Always verify manufacturer specifications rather than assuming voltage compatibility.

Voltage Optimization for Maximum Battery Life and Performance

Proper voltage management extends battery lifespan by 30-50% while maintaining optimal device performance. This requires understanding charge thresholds, discharge curves, and environmental factors that impact voltage stability.

Optimal Charging Voltage Strategies

Different battery chemistries require specific charging approaches:

- Li-ion: Maintain between 20-80% charge (3.2V-4.0V) to prevent stress on electrodes – full 4.2V charges should be reserved for when maximum capacity is needed

- Lead-acid: Equalize charging at 14.4-14.8V periodically to prevent sulfation, but avoid exceeding 15V which causes gassing

- NiMH: Use -ΔV detection (5-10mV drop per cell) to prevent overcharging damage at 1.55V/cell

Discharge Voltage Cutoffs

Setting proper low-voltage limits prevents irreversible damage:

| Battery Type | Minimum Voltage | Recovery Procedure |

|---|---|---|

| Li-ion | 3.0V | Slow charge at 0.1C if below 2.5V |

| Lead-acid | 10.5V (12V system) | Equalization charge at 15V for 4 hours |

| NiMH | 0.9V/cell | Full discharge/charge cycle to reset memory |

Environmental Voltage Compensation

Temperature dramatically affects voltage characteristics:

- Cold weather: Lithium batteries need pre-warming to 0°C before charging – charging at -20°C can plate lithium and cause shorts

- Hot climates: Reduce float voltage by 3mV/°C above 25°C for lead-acid batteries to prevent corrosion

- High altitude: Thin air reduces cooling – decrease charge voltage by 0.5% per 300m above 1500m

Professional Maintenance Tips

For critical systems:

- Use battery monitoring systems (BMS) that track individual cell voltages in packs

- Implement voltage profiling – record discharge curves monthly to detect aging patterns

- For solar systems, set absorption voltage 0.3V higher in winter to compensate for slower chemical reactions

Advanced Voltage Management for Battery Longevity and Safety

Mastering voltage control techniques can transform battery performance, particularly in demanding applications where both lifespan and reliability are critical.

Precision Voltage Balancing in Battery Packs

Multi-cell systems require meticulous voltage matching to prevent premature failure:

| Balancing Technique | Voltage Threshold | Best Applications | Efficiency Impact |

|---|---|---|---|

| Passive Balancing | ±20mV | Consumer electronics | 85-90% efficient |

| Active Balancing | ±5mV | EV batteries, grid storage | 92-95% efficient |

| Charge Shuttling | ±2mV | Aerospace systems | 97%+ efficient |

Active balancing systems can extend pack life by 40% compared to passive systems, justifying their higher cost in professional applications.

Voltage Ripple and Its Hidden Impacts

AC components in DC charging systems create subtle voltage fluctuations that degrade batteries:

- Acceptable ripple: <1% of nominal voltage for Li-ion (40mV for 4V systems)

- Critical effects: Each 100mV of ripple at 100kHz frequency reduces cycle life by approximately 15%

- Measurement: Requires true-RMS multimeter with ≥1MHz bandwidth to detect high-frequency artifacts

Premium chargers incorporate multi-stage LC filtering to maintain ripple below 0.5%.

Voltage Recovery Techniques for Aged Batteries

Specialized conditioning can restore partially degraded cells:

- Pulsed reconditioning: Applying 2-5C pulses at 50% duty cycle helps break down crystalline formations in NiMH

- Deep cycling: For lead-acid, complete discharge to 1.75V/cell followed by slow 0.05C charge can recover 10-15% capacity

- Lithium wake-up: Cells below 2.5V should be charged at 0.02C until reaching 3.0V before normal charging

These methods can extend usable life by 6-12 months when properly executed.

Emerging Voltage Management Technologies

Future systems are adopting innovative approaches:

- AI-powered voltage prediction: Machine learning models analyzing historical voltage patterns to optimize charging

- Self-healing electrolytes: Materials that automatically adjust internal resistance to maintain stable voltage output

- Quantum voltage sensors: Nanoscale detectors providing ±0.1mV accuracy for critical medical implants

These advancements promise to revolutionize how we monitor and maintain battery voltage in coming years.

Voltage Regulation Techniques for Critical Power Systems

Maintaining precise voltage control becomes paramount in applications where power fluctuations can cause catastrophic failures.

Multi-Stage Voltage Regulation Architectures

Sophisticated systems employ layered regulation approaches:

- Primary regulation: Bulk conversion (e.g., 48V to 12V) using switched-mode power supplies with ≥90% efficiency

- Secondary regulation: Linear regulators provide ±1% voltage stability for noise-sensitive components

- Tertiary conditioning: Active filtering removes residual ripple below 10mV p-p for precision analog circuits

Medical imaging systems often use this triple-stage approach to maintain sub-millivolt stability during scans.

Dynamic Voltage Scaling in Smart Systems

Modern processors employ real-time voltage adjustment:

- DVFS (Dynamic Voltage Frequency Scaling): Reduces core voltage by 100-300mV during low-load periods

- AVS (Adaptive Voltage Scaling): Uses on-die sensors to adjust voltage within 25mV of minimum stable level

- Race-to-sleep: Brief high-voltage bursts (1.2V to 1.35V) for quick task completion then rapid power-down

These techniques can reduce processor power consumption by 40% while maintaining performance.

Voltage Monitoring and Fail-Safe Protocols

Critical infrastructure implements redundant monitoring:

| Monitoring Tier | Response Time | Action Threshold | Corrective Action |

|---|---|---|---|

| Primary | 10μs | ±5% nominal | Adjust regulator output |

| Secondary | 100ms | ±10% nominal | Switch to backup supply |

| Tertiary | 1s | ±20% nominal | Graceful system shutdown |

Aircraft systems typically implement all three tiers with optical isolation between monitoring circuits.

Voltage Compensation for Transmission Losses

Long-distance power distribution requires sophisticated compensation:

- Voltage boost: Adds 2-5% extra at source to compensate for line losses

- Reactive power control: Adjusts voltage phase angle to reduce I²R losses

- Automatic tap changers: Transformers with 32+ tap positions adjust voltage in 0.625% increments

Smart grid systems now use predictive algorithms to anticipate load changes and pre-adjust voltage levels.

These advanced techniques demonstrate how modern systems achieve voltage stability within 0.1% even under rapidly changing load conditions – a 100x improvement over basic regulation approaches.

System-Wide Voltage Optimization and Lifetime Management

True voltage mastery requires understanding how battery systems interact with complete power networks over their entire lifecycle.

Comprehensive Voltage Performance Metrics

Advanced systems track multiple voltage parameters simultaneously:

| Metric | Ideal Range | Measurement Protocol | Failure Implications |

|---|---|---|---|

| Static Voltage | ±1% of nominal | 24-hour averaged readings | Indicates cell degradation |

| Dynamic Sag | <5% drop at max load | 100ms sampling during load spikes | Reveals internal resistance growth |

| Recovery Time | <2 seconds to 95% | From 50% discharge pulse | Shows electrolyte depletion |

| Cell Delta | <15mV in packs | Simultaneous multi-channel | Predicts pack imbalance |

Data center UPS systems typically log these parameters every 15 minutes for predictive maintenance.

Voltage-Centric Predictive Maintenance

Advanced analytics transform voltage data into actionable insights:

- Trend analysis: Machine learning identifies micro-voltage fluctuations (50-100μV changes) that precede failures

- Pattern matching: Compares current voltage profiles against 10,000+ known failure scenarios

- Stress modeling: Calculates cumulative voltage stress from charge/discharge cycles and environmental factors

Modern battery management systems can now predict cell failures with 92% accuracy 30+ days in advance.

Voltage Compliance and Certification

Meeting international standards requires rigorous testing:

- IEC 62660-3: Mandates 500+ voltage cycles with <3% deviation

- MIL-STD-810: Verifies voltage stability across -40°C to +71°C

- UL 1973: Requires voltage containment during thermal runaway

Certification testing now includes “voltage attack” simulations where systems must maintain stability despite deliberate power disturbances.

End-of-Life Voltage Thresholds

Professional retirement criteria consider multiple factors:

- Capacity-based: Retire when nominal voltage can’t sustain 80% rated capacity

- Efficiency-based: Replace when charge voltage exceeds discharge by >15%

- Safety-based: Decommission if self-discharge causes >5% voltage drop/week

Grid storage facilities typically implement all three criteria with automated retirement triggers.

This comprehensive approach transforms voltage from a simple measurement into the central nervous system of battery health monitoring, enabling optimized performance throughout the asset lifecycle while preventing catastrophic failures.

Conclusion: Mastering Battery Voltage for Optimal Performance

Throughout this comprehensive guide, we’ve explored the critical role of voltage in battery systems—from basic nominal values to advanced management techniques.

You’ve learned how voltage varies by chemistry (1.5V alkaline to 3.7V Li-ion), why accurate measurement under load matters, and how sophisticated regulation extends battery life. The key takeaway? Voltage isn’t just a number—it’s the vital sign of your battery’s health and performance.

Whether you’re maintaining a car battery or designing a solar array, applying these voltage principles will ensure safer, more efficient, and longer-lasting power systems. Put this knowledge into action today—start by verifying your devices’ voltage requirements and implementing proper monitoring practices.

Frequently Asked Questions About Battery Voltage

What exactly does battery voltage indicate?

Voltage represents the electrical potential difference between a battery’s terminals, determining how much energy it can deliver.

A standard AA alkaline battery starts at 1.5V when new, while a car battery measures 12.6V when fully charged. However, actual voltage varies during use – lithium-ion batteries operate between 3.0V (empty) to 4.2V (full).

Voltage drops as the battery discharges, making it a reliable indicator of remaining capacity when measured properly under load.

Why does my multimeter show different voltages for the same battery?

Voltage readings vary due to several factors: measurement timing (resting vs under load), temperature (voltage drops in cold), and meter accuracy.

A resting alkaline AA may show 1.5V, but drop to 1.2V when powering a flashlight. High-quality digital multimeters (like Fluke models) provide more consistent readings than cheap analog testers. Always measure under typical load conditions for accurate assessments.

How can I tell if a battery is bad using voltage readings?

Compare your reading to expected values: a 12V lead-acid battery below 11.8V at rest is likely sulfated. For lithium-ion, below 3.0V indicates deep discharge.

Also watch for rapid voltage drop under load – if a “full” 1.5V AA immediately drops to 1.0V when used, it’s depleted. Note that some smart batteries may show 0V when completely dead but are actually recoverable with specialized chargers.

Can I use a higher voltage battery if it fits the device?

Generally no – excess voltage can damage electronics. While a device designed for 3V might work briefly with 3.7V lithium, prolonged use risks overheating components.

The exception: some devices have wide-input voltage regulators (like 5-20V for power tools). Always check manufacturer specifications. For example, replacing 1.5V alkalines with 1.2V NiMH rechargeables is usually safe, though runtime may be shorter.

Why do rechargeable batteries have lower nominal voltages?

Different chemistries produce different voltages: NiMH operates at 1.2V versus alkaline’s 1.5V because nickel-metal hydride reactions create less electrical potential.

However, rechargeables maintain their voltage better under load. A NiMH may deliver 1.2V consistently, while an alkaline drops from 1.5V to 1.0V during use. Modern devices are designed to accommodate these differences through wider operating voltage ranges.

How does temperature affect battery voltage?

Cold temperatures temporarily reduce voltage (a 12V car battery may show 11V at -20°C), while heat increases it. Lithium-ion batteries lose about 0.5% voltage per °C below 20°C.

In extreme cold (-40°C), some batteries may show normal voltage but deliver no current. Always warm cold batteries before testing or charging. High temperatures (above 45°C) can cause permanent voltage capacity loss in most chemistries.

What’s the safest way to measure high-voltage battery packs?

For packs over 30V (like ebike batteries), use CAT III-rated multimeters with insulated probes. Always measure one hand behind your back to prevent current across the chest.

Check individual cell voltages first before pack voltage. For example, a 48V lithium pack should show 13 cells at 3.6-4.2V each. Never probe live terminals with metallic jewelry or tools.

How often should I check my deep cycle battery’s voltage?

For maintenance-free lead-acid, check monthly (12.6V+ is ideal). Lithium systems need bi-monthly checks – any cell below 3.0V requires attention.

Solar systems benefit from automated monitors that track daily voltage fluctuations. Critical applications (medical, marine) should implement continuous monitoring with voltage alarms set at 10% above/below normal operating range.