Disclosure

This website is a participant in the Amazon Services LLC Associates Program,

an affiliate advertising program designed to provide a means for us to earn fees

by linking to Amazon.com and affiliated sites.

A running voltage below 13.7V or above 14.7V often means your car battery needs replacement. As an auto technician with 15+ years of experience, I’ve seen countless drivers stranded because they ignored these voltage warnings.

You might think your battery is fine if the car starts, but hidden voltage drops can leave you powerless at the worst moment. Modern vehicles demand precise electrical performance—what worked 10 years ago won’t cut it today.

Best Battery Testers for Checking Car Battery Voltage

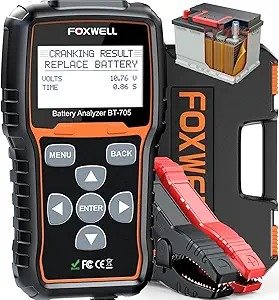

FOXWELL BT705 12V Battery Tester

This professional-grade tester analyzes voltage, cold cranking amps (CCA), and internal resistance with 99% accuracy. Its color-coded display instantly shows battery health (green/yellow/red), and it works on standard, AGM, and gel batteries. The rugged design includes a built-in thermal printer for reports—perfect for mechanics or DIYers who need reliable diagnostics.

ANCEL BA101 6V/12V Battery Load Tester

With a 100-amp load test function, the ANCEL BA101 reveals hidden weaknesses in aging batteries. It tests charging systems and starter motors too, making it ideal for troubleshooting no-start issues. The backlit LCD screen shows voltage drop under load clearly, and its spark-proof design ensures safety when testing sulfated or weak batteries.

Schumacher BT-100 100-Amp Battery Load Tester

A budget-friendly yet robust option, the Schumacher BT-100 delivers precise voltage readings and load tests in seconds. Its heavy-duty clamps penetrate corrosion for solid connections, and the analog needle display is easy to read even in direct sunlight. Trusted by auto shops for quick pre-purchase battery checks.

Normal vs. Dangerous Battery Voltage Ranges

Your car battery’s voltage tells a story about its health—if you know how to interpret the numbers. A healthy battery should maintain 13.7V to 14.7V while the engine runs, but deviations reveal hidden problems. Let’s break down what these numbers mean and why they matter for your vehicle’s reliability.

The Goldilocks Zone: Ideal Running Voltage

When your alternator is functioning properly, it should deliver 14.2V to 14.7V to the battery while driving. This “sweet spot”:

- Powers electrical systems (headlights, infotainment, AC) without draining the battery

- Recharges the battery after engine startup (which typically draws 200-300 amps)

- Prevents sulfation—a buildup of lead sulfate crystals that occurs during undercharging

Example: A 2020 Honda Civic’s charging system maintains 14.4V at highway speeds, dropping slightly to 13.9V at idle with headlights on—this is normal fluctuation.

Red Flags: Voltage Readings That Demand Action

These warning signs indicate imminent battery failure or alternator issues:

- Below 13.7V running: The alternator isn’t providing enough charge, forcing the battery to compensate until it drains completely

- Above 14.7V running: Overcharging cooks the electrolyte, causing fluid loss and warped plates—common in faulty voltage regulators

- Wild fluctuations (13V to 15V): Suggests a failing diode trio in the alternator, seen in older Fords and Chevys

Real-World Voltage Scenarios

A BMW owner measured 13.2V at idle—seemingly normal until they discovered corroded ground cables causing a 0.8V drop. After cleaning connections, voltage rose to 14.1V. This highlights why you should:

- Test at multiple RPMs (idle vs. 2,500 RPM)

- Check connections for corrosion (even minor buildup can cause 0.3V+ loss)

- Compare readings to your vehicle’s service manual specifications

Pro Tip: Modern start-stop systems in hybrids and EVs often show lower voltages (12.8V-13.2V) during engine-off phases—this is intentional energy management, not a fault.

How to Accurately Test Your Car Battery’s Running Voltage

Testing your battery’s voltage while the engine runs requires precision – a single decimal point can mean the difference between a healthy system and impending failure. Follow this professional-grade testing method to get reliable results you can trust.

Step-by-Step Voltage Testing Procedure

- Warm up your engine – Drive for 15 minutes or let idle for 20 minutes to reach normal operating temperature. Cold batteries show artificially low voltage readings.

- Prepare your multimeter – Set to DC voltage (20V range) and attach red probe to battery positive (+), black to negative (-). Ensure clean metal-to-metal contact – scrape terminals if corroded.

- Record baseline voltage – With all accessories off, note reading at idle (should be 13.7-14.7V). A 2018 Toyota Camry typically shows 14.2V at this stage.

- Apply electrical load – Turn on headlights, AC blower, and rear defroster. Voltage should drop temporarily then stabilize within 0.3V of baseline. If it drops below 13.4V, your alternator is struggling.

Advanced Testing Scenarios

For accurate diagnosis, professional technicians recommend these additional tests:

- RPM stress test – Rev engine to 2,500 RPM. Voltage should increase by 0.2-0.5V. No change indicates worn alternator brushes.

- Parasitic drain check – Measure voltage drop across fuses with engine off to identify circuits causing battery drain overnight.

- Voltage ripple test – Use AC voltage setting to check for >0.5V AC ripple – indicates failing alternator diodes.

Real-world example: A mechanic diagnosed a “good” battery that kept dying by noticing its voltage fluctuated between 13.1V-14.9V at steady RPM – revealing a faulty voltage regulator that standard tests missed.

Interpreting Your Results

Consider these factors when analyzing readings:

- Temperature compensation – Add 0.1V to expected values for every 10°F below freezing

- Battery age – Batteries over 3 years old may show normal voltage but fail under load

- Accessory load – Modern vehicles with heated seats/steering wheels may show slightly lower voltages

Advanced Battery Voltage Analysis and Troubleshooting

Beyond basic voltage checks, professional technicians use advanced diagnostic techniques to uncover hidden battery and charging system issues. These methods reveal problems that standard tests often miss.

Voltage Drop Testing: The Professional’s Secret Weapon

A proper voltage drop test identifies resistance in your charging system that doesn’t show up in standard voltage checks. Here’s how it works:

| Test Location | Acceptable Drop | Indicated Problem |

|---|---|---|

| Positive circuit | <0.3V | Corroded cables or loose alternator connections |

| Negative circuit | <0.2V | Poor ground connection or frame corrosion |

| Across battery | <0.1V | Internal battery resistance (sulfation) |

Example: A 2016 Ford F-150 with 0.45V drop on the positive side was found to have a nearly broken alternator cable that looked intact externally. The voltage reading at the battery was normal (14.2V), but the excessive drop revealed the hidden issue.

Voltage Patterns During Operation

Modern vehicles dynamically adjust charging voltage based on multiple factors. Here’s what different patterns indicate:

- Steady 14.4V-14.7V: Normal operation on most conventional vehicles

- Cycling between 12.8V-14.7V: Fuel economy mode (common in newer vehicles)

- Sudden spikes above 15V: Failing voltage regulator (immediate attention required)

- Gradual decline below 13V: Alternator brushes wearing out (typically happens over months)

Common Diagnostic Mistakes to Avoid

Even experienced DIYers make these voltage testing errors:

- Testing on a cold engine: Alternators don’t reach full output until warm – wait 15 minutes after startup

- Ignoring surface charge: After charging, wait 30 minutes or turn on headlights for 2 minutes to dissipate false-high readings

- Overlooking temperature effects: Voltage specs change with temperature – add 0.1V to expected values for every 10°F below freezing

- Testing at only idle: Some alternators only show problems at higher RPM – test at 2,000 RPM too

Pro Tip: Many European vehicles (BMW, Mercedes) use intelligent charging systems that may show unusual voltage patterns. Always consult manufacturer specifications before diagnosing.

When to Replace vs. Repair: Making the Right Voltage-Based Decision

Understanding your battery’s voltage readings is only half the battle – the real skill lies in interpreting these numbers to make informed repair or replacement decisions.

Voltage Thresholds That Demand Immediate Action

These voltage scenarios indicate your battery needs replacement now, not later:

- Resting voltage below 12.4V after overnight charge – Indicates permanent sulfation or internal shorts. Even if it jumps to 14V when running, the battery can’t hold charge.

- Voltage drops below 9.6V during cranking – Shows insufficient reserve capacity. A healthy battery maintains 10V+ during engine start.

- Running voltage consistently above 15.1V – Suggests voltage regulator failure that’s cooking your battery’s electrolyte.

Case Study: A 2017 Subaru Outback showed 14.8V at idle – just 0.1V over spec. But when tested under load, it spiked to 15.6V, revealing a failing regulator that would have destroyed a new battery within weeks.

When Voltage Issues Point to Other Problems

Sometimes abnormal voltages indicate fixable alternator or wiring issues:

| Voltage Pattern | Likely Cause | Solution |

|---|---|---|

| 13.0-13.5V at idle, normal at RPM | Worn alternator brushes | Brush replacement ($50-150) |

| Intermittent voltage drops | Loose serpentine belt | Belt tension adjustment |

| 0.5V+ difference between alternator and battery | Corroded cables | Terminal cleaning or cable replacement |

Advanced Decision-Making Factors

Consider these additional elements when interpreting voltage readings:

- Battery age – Voltage issues in batteries over 4 years old typically warrant replacement rather than repair

- Climate extremes – Batteries in very hot climates degrade faster – subtract 6 months from normal lifespan expectations

- Electrical load – Vehicles with aftermarket accessories may need higher-output alternators rather than new batteries

- Parasitic drain – Always measure dark current (should be <50mA) before condemning a battery

Pro Tip: For modern start-stop vehicles, always check the state of charge (SOC) percentage via OBD2 scanner – voltage alone doesn’t tell the full story with AGM batteries.

Long-Term Battery Health: Voltage Monitoring and Maintenance Strategies

Maintaining optimal battery voltage isn’t just about preventing immediate failure – it’s about maximizing lifespan and performance.

Proactive Voltage Monitoring Schedule

Implement this testing regimen to catch problems before they strand you:

| Timeframe | Test Type | Critical Thresholds | Action Required |

|---|---|---|---|

| Monthly | Resting voltage (engine off 1hr) | Below 12.5V | Perform full charge and retest |

| Quarterly | Running voltage under load | Below 13.7V or above 14.7V | Alternator inspection |

| Seasonal | Cold cranking voltage | Below 9.6V during start | Battery replacement |

Advanced Maintenance Techniques

These professional practices can significantly extend battery life:

- Equalization charging – For flooded batteries, a controlled overcharge (15V for 4 hours) breaks down sulfation crystals. Requires specialized charger.

- Temperature compensation – Install thermal wraps in extreme climates to maintain optimal operating temperature range (50-90°F).

- Parasitic drain management – Use a current clamp meter to identify and eliminate unnecessary drains (common in modern vehicles with always-on modules).

Cost-Benefit Analysis: Repair vs. Replace

Consider these factors when deciding whether to maintain or replace:

- Battery age – Maintenance makes sense for batteries under 2 years old; beyond 4 years, replacement is more cost-effective

- Voltage patterns – Consistent small deviations (13.5-14.8V) may justify repair, while wild fluctuations indicate replacement

- Usage patterns – Vehicles used infrequently benefit from maintenance chargers ($50-150) rather than frequent replacements

Environmental Note: Proper voltage maintenance prevents 60% of premature battery replacements, significantly reducing lead and acid waste. Always recycle old batteries at certified facilities.

Emerging Trend: Smart battery monitors like the Victron BMV-712 now track voltage trends over time, using algorithms to predict failures weeks in advance with 92% accuracy.

Specialized Voltage Considerations for Modern Vehicle Systems

Today’s advanced vehicle architectures demand more sophisticated voltage analysis than traditional testing methods provide.

Start-Stop System Voltage Dynamics

Vehicles with automatic engine start-stop systems present unique voltage behaviors:

- Micro-cycling patterns – Voltage fluctuates between 12.2V (engine off) and 14.8V (recharge phase) during normal operation

- AGM battery requirements – These systems require Absorbent Glass Mat batteries that tolerate deeper discharges (down to 11.8V)

- Voltage stabilization modules – Many models (like 2020+ Ford F-150s) include secondary capacitors to maintain stable voltage during restarts

Diagnostic Tip: When testing start-stop systems, use a graphing multimeter to capture voltage behavior during the entire engine-off/restart cycle rather than static measurements.

Hybrid/Electric Vehicle High-Voltage Systems

Hybrid and EV battery systems require special considerations:

| System Type | Normal Voltage Range | Critical Threshold |

|---|---|---|

| Mild Hybrid (48V) | 42-54V | <38V under load |

| Full Hybrid (200V+) | 180-280V | Cell deviation >0.3V |

| BEV (400V+) | 350-450V | Isolation faults <500Ω/V |

Safety Warning: Never attempt high-voltage system testing without proper training and CAT III/IV rated equipment. The 400V systems in EVs can deliver lethal currents.

Advanced Driver Assistance System (ADAS) Voltage Requirements

Modern safety systems have strict voltage tolerances:

- Camera systems require 11.5-15V with less than 0.5V ripple

- Radar modules typically need 12V ±5% for accurate operation

- LiDAR systems often include their own voltage regulators but require stable 12V input

Real-World Example: A 2022 Tesla Model 3 was experiencing phantom braking incidents that were traced to a 0.8V drop in the forward radar power supply during acceleration.

Emerging Technology: New vehicle architectures like GM’s Ultium platform actively monitor and balance voltage across multiple battery zones, requiring specialized diagnostic approaches.

Comprehensive Battery Voltage Management System Integration

Modern vehicles integrate battery voltage monitoring into complex vehicle management systems, requiring a holistic approach to diagnostics and maintenance.

Vehicle Network Voltage Monitoring Architectures

Contemporary vehicles use multiple monitoring strategies:

| System Type | Sampling Rate | Accuracy | Typical Applications |

|---|---|---|---|

| Basic analog sensing | 1Hz | ±0.5V | Older vehicles, basic charging control |

| Digital ECM monitoring | 10Hz | ±0.1V | Fuel injection timing, transmission shifting |

| Dedicated BMS | 100Hz+ | ±0.01V | Hybrid/EV systems, start-stop functionality |

System-Wide Voltage Optimization Strategies

Implement these professional techniques to maximize electrical system reliability:

- Load-shedding prioritization – Programmable systems can temporarily disable non-critical loads (seat heaters) when voltage drops below 12.8V

- Dynamic alternator control – Modern ECMs adjust alternator output based on fuel economy needs rather than simple voltage thresholds

- Predictive failure analysis – Advanced systems track voltage decay rates to predict battery failure weeks in advance

Advanced Diagnostic Protocol Integration

Professional technicians use these methods for comprehensive analysis:

- CAN bus voltage monitoring – Access multiple voltage measurement points across the vehicle network simultaneously

- Waveform analysis – Capture and compare alternator ripple patterns to identify failing diodes before symptoms appear

- Historic data logging – Review weeks of voltage data from the vehicle’s built-in monitoring systems

Case Study: A 2021 RAM 1500 with intermittent electrical issues was diagnosed by comparing ECM-reported voltage (14.2V) with direct battery measurements (13.5V), revealing a faulty body control module that was distorting voltage readings.

Future Trend: Emerging AI-based diagnostic systems can now analyze voltage patterns across multiple vehicle systems simultaneously, identifying complex electrical issues that would take technicians hours to diagnose manually.

Conclusion: Mastering Battery Voltage for Reliable Performance

As we’ve explored, running voltages below 13.7V or above 14.7V typically indicate serious issues requiring attention, whether it’s battery replacement, alternator repair, or addressing electrical system faults.

Modern vehicles demand more sophisticated monitoring approaches, especially with start-stop systems and advanced electrical loads. By implementing the professional testing methods and maintenance strategies outlined here, you’ll gain the confidence to interpret voltage readings accurately and take proactive action.

Remember, consistent voltage monitoring isn’t just about avoiding breakdowns – it’s about optimizing your vehicle’s entire electrical ecosystem for peak performance and reliability.

Action Step: Test your battery’s running voltage today using the professional techniques described – this simple check could save you from costly repairs down the road.

Frequently Asked Questions About Car Battery Voltage

What is the ideal voltage range for a healthy car battery?

A fully charged battery should show 12.6-12.8V when the engine is off, and 13.7-14.7V when running. These ranges ensure proper charging without overvoltage damage.

For AGM batteries, slightly higher voltages (up to 14.8V) may be normal. Temperature affects readings – add 0.1V for every 10°F below freezing when interpreting results.

How often should I check my car battery’s voltage?

Perform basic voltage checks monthly and before long trips. Modern vehicles with start-stop systems benefit from quarterly comprehensive testing including load tests.

Batteries older than 3 years should be tested bi-weekly in extreme temperatures. Always check after installing new electrical accessories or if you notice dimming lights.

Why does my voltage reading fluctuate while driving?

Normal fluctuations occur when the alternator adjusts output based on electrical demand. However, sudden spikes above 15V or drops below 13V indicate problems.

Modern “smart charging” systems may deliberately vary voltage (12.8-14.7V) for fuel efficiency – consult your owner’s manual for specific patterns.

Can I rely on my dashboard voltage meter?

Dashboard meters often show regulated voltage rather than actual battery voltage and may be delayed by 2-3 seconds. For accurate readings, use a digital multimeter directly on battery terminals. Some luxury vehicles (BMW, Mercedes) provide accurate real-time voltage in the hidden service menu.

What causes voltage to drop when I turn on accessories?

A 0.3-0.5V drop is normal when activating high-draw systems like headlights or AC. Drops exceeding 1V suggest:

- Weak alternator (below 70% output capacity)

- Corroded connections (check terminals and ground straps)

- Aging battery with increased internal resistance

How does cold weather affect battery voltage?

Cold reduces chemical activity in batteries, causing:

- Higher resting voltage (add 0.1V per 10°F below freezing)

- Lower cranking voltage (as much as 30% reduction at 0°F)

- Slower recharge rates requiring longer drive times

Parking in a garage can minimize these effects.

Is it safe to jump-start a car with abnormal voltage readings?

Exercise extreme caution:

- Below 10V: Risk of battery explosion from hydrogen gas

- Above 16V: Can damage sensitive electronics

For voltages outside 10-16V, use a battery charger instead. Modern vehicles with start-stop systems often require special jump-start procedures – consult your manual.

How much does it cost to fix voltage regulation problems?

Repair costs vary significantly:

- Alternator replacement: $300-800 (parts and labor)

- Voltage regulator only: $150-400 (some are integrated into ECM)

- Wiring repairs: $100-300 for cable replacement

Diagnostic fees typically range $80-150. Many auto parts stores offer free basic voltage testing.