Disclosure

This website is a participant in the Amazon Services LLC Associates Program,

an affiliate advertising program designed to provide a means for us to earn fees

by linking to Amazon.com and affiliated sites.

A fully charged 6V golf cart battery should measure 6.3 to 6.4 volts—but here’s why most owners get this wrong. You might assume a “6V” label means your battery always reads exactly 6.0 volts, yet reality reveals a far more nuanced picture.

Golf cart batteries operate within a voltage range, and understanding this could mean the difference between a long-lasting power source and an unexpected breakdown on the course. With electric carts surging in popularity, knowing how to measure and maintain your battery’s voltage isn’t just technical trivia—it’s the key to avoiding costly replacements and maximizing performance.

Many golfers panic when their multimeter shows 6.5V after charging, fearing overcharging damage, or despair at 5.8V, assuming failure. But voltage fluctuates based on temperature, load, and charge cycles—what matters is interpreting these readings like a pro.

Best Multimeters for Testing 6V Golf Cart Batteries

Fluke 115 Compact True-RMS Digital Multimeter

Trusted by professionals, the Fluke 115 delivers precise voltage readings (0.5% accuracy) with its True-RMS technology, critical for detecting subtle drops in 6V battery health. Its rugged design withstands garage environments, while the large backlit display ensures readability in low light.

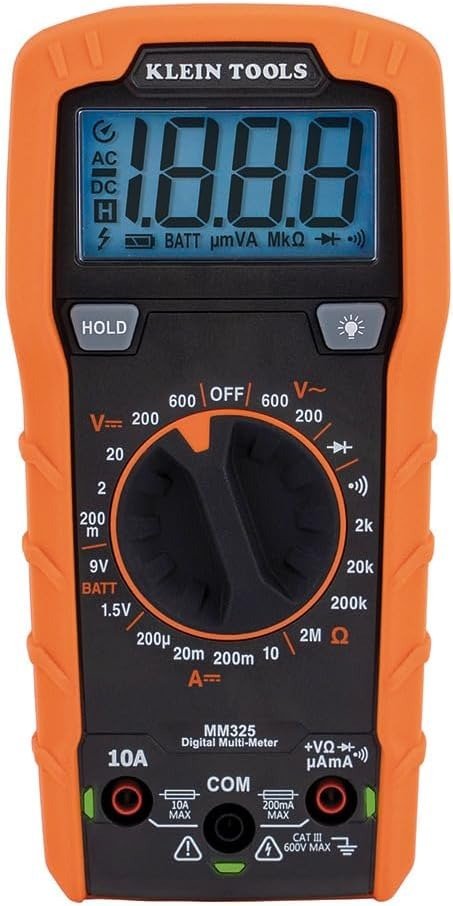

Klein Tools MM325 Auto-Ranging Multimeter

Ideal for DIY golf cart owners, the MM325 auto-ranges between 0-60V, eliminating manual adjustments. Its IP67 waterproof rating and built-in temperature probe help diagnose voltage fluctuations caused by heat—a common issue in battery compartments during summer rounds.

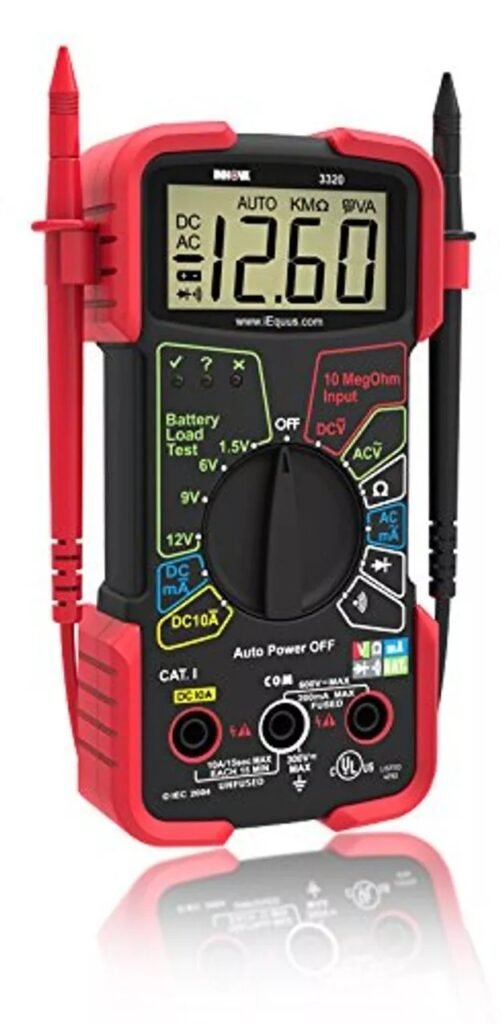

INNOVA 3320 Auto-Ranging Digital Multimeter

Budget-friendly yet reliable, the INNOVA 3320 features a dedicated battery test mode for 6V systems and a low-battery indicator. Its 10MΩ input impedance prevents false readings from residual charge, crucial when testing older golf cart batteries with surface voltage.

6V Golf Cart Battery Voltage: The Complete Breakdown

What Does “6V” Really Mean?

When manufacturers label a battery as “6V,” they’re referring to its nominal voltage—the average voltage during standard discharge. In reality, your battery’s voltage constantly fluctuates between:

- 6.37-6.4V when fully charged (resting for 12+ hours after charging)

- 6.0-6.1V at 50% discharge (the minimum safe level before damage occurs)

- 5.5V or below indicates severe discharge and potential sulfation

This variance occurs because lead-acid batteries (used in 95% of golf carts) experience voltage sag under load and recovery when idle—a phenomenon called surface charge.

Why Voltage Alone Doesn’t Tell the Full Story

A common mistake is judging battery health solely by voltage readings. While important, voltage must be interpreted alongside:

- Specific gravity (1.277 for fully charged flooded batteries)

- Temperature (voltage drops 0.01V per °F below 80°F)

- Load testing (voltage shouldn’t drop below 5V under 75A load for 15 seconds)

For example, a battery showing 6.3V might still fail if it plummets to 4V when climbing hills—a sign of damaged plates.

The Critical Voltage Thresholds Every Owner Should Know

Charging Phase: During charging, voltages temporarily spike to 7.2-7.5V (absorption stage) before settling. This is normal—modern chargers reduce to 6.8V in float mode.

Discharge Warning Signs: If your battery bank (four 6V batteries in series) reads:

- Under 24.4V (6.1V per battery) – Immediate recharge needed

- 22.8V (5.7V per battery) – Risk of permanent capacity loss

- 21V (5.25V per battery) – Deep discharge damage likely occurred

Real-World Voltage Scenarios Explained

A golf cart used for 18 holes typically discharges batteries to ~6.2V. However, voltage drops further during:

- Hill climbs (temporary 5.8-6.0V readings are normal under load)

- Cold mornings (voltage may read 0.2V lower until batteries warm up)

- Accessory use (LED lights drain ~0.1V per hour when parked)

Professional courses use mid-point voltage testing—measuring between batteries 2 and 3 in a 48V system—to identify weak cells before failures occur.

How to Accurately Test Your 6V Golf Cart Battery Voltage

Pre-Test Preparation: Setting Up for Success

Before testing, ensure your battery has rested for at least 4 hours after charging or discharging to eliminate surface charge distortion. Gather:

- A digital multimeter with 0.1V resolution (analog meters lack precision)

- Safety gloves and glasses (batteries contain sulfuric acid)

- A clean cloth to wipe terminals (corrosion causes false readings)

Temperature dramatically affects readings – perform tests at room temperature (70-80°F) whenever possible. Cold batteries show artificially low voltages, while hot batteries may mask underlying issues.

The Professional’s Step-by-Step Testing Method

- Set your multimeter to DC voltage (20V range) and verify calibration by testing a known 6V source

- Connect probes – red to positive (usually marked red/+), black to negative (black/-)

- Take three readings:

- Resting voltage (no load)

- Under load (while pressing accelerator)

- Recovery voltage (5 minutes after load)

- Compare results:A healthy battery will show:

- 6.37-6.4V resting

- No lower than 5.8V under load

- Returns to within 0.1V of resting voltage after recovery

Interpreting Your Voltage Readings Like a Pro

Common voltage patterns and their meanings:

- 6.4V resting but drops to 5.5V under load – Likely sulfation buildup (needs desulfation charging)

- 6.1V after overnight rest – Possible parasitic drain (test with all accessories off)

- 6.6V or higher – Overcharging risk (check charger settings)

For battery banks, individual batteries shouldn’t vary more than 0.2V from each other. A 0.5V difference indicates a weak cell needing replacement.

Troubleshooting Voltage Irregularities

When readings don’t match expectations:

- Fluctuating numbers – Check for loose terminal connections (torque to 8-10 ft-lbs)

- Consistently low voltage – Test each cell with a hydrometer (should be 1.265 ±0.005)

- Sudden voltage drops – Inspect for physical damage or warped plates

Pro tip: Record voltage trends weekly – gradual declines reveal aging batteries before failures occur. Modern battery monitors like the Victron BMV-712 track this automatically.

Advanced Voltage Maintenance: Optimizing 6V Golf Cart Battery Performance

The Chemistry Behind Voltage Fluctuations

Lead-acid batteries operate through electrochemical reactions where:

- Charging: PbSO₄ (lead sulfate) converts to PbO₂ (positive plate) and Pb (negative plate)

- Discharging: The reverse reaction occurs, producing PbSO₄ and 2.04V per cell (6.12V total)

This explains why:

| State | Chemical Reaction | Voltage Impact |

|---|---|---|

| Overcharged | Excess water electrolysis (2H₂O→2H₂+O₂) | Voltage spikes >7V |

| Sulfated | PbSO₄ crystallization | Voltage drops 0.2-0.5V |

| Balanced | Ideal stoichiometric conversion | Stable 6.3-6.4V |

Professional maintenance requires understanding these reactions – for instance, equalizing charges (controlled overcharging) at 7.3V breaks sulfate crystals but risks dehydration if overdone.

Precision Charging Techniques for Voltage Stability

Optimal charging requires matching charger specs to your battery’s:

- Absorption Voltage: 7.2-7.5V (temperature-compensated)

- Float Voltage: 6.6-6.8V (prevents overcharge)

- Current: 10-30% of Ah rating (e.g., 22A for 220Ah battery)

Advanced chargers like the Lester Summit II automatically adjust these parameters based on:

- Battery temperature (via sensor)

- Historical usage patterns

- Specific gravity readings (if entered manually)

Common mistake: Using automotive chargers that apply 14V+ to 6V systems, causing catastrophic plate corrosion.

Voltage-Based Maintenance Schedule

Follow this voltage-monitored routine:

| Frequency | Action | Target Voltage | Tolerance |

|---|---|---|---|

| Daily | Post-round voltage check | >6.1V | ±0.05V |

| Weekly | Equalization charge | 7.3V | ±0.1V |

| Monthly | Load test | >5.8V under load | ±0.2V |

Pro tip: When storing carts >30 days, maintain voltage at 6.3V using maintainers like BatteryMINDer 2012-AGM – this prevents sulfation without overcharging.

Diagnosing Voltage Anomalies

When voltages deviate from norms:

- High voltage (6.6V+):

- Check charger float setting (should be 6.8V max)

- Test for dry cells (low electrolyte increases resistance)

- Low voltage (5.8V-):

- Measure specific gravity (should be 1.265±0.005)

- Inspect for shorts (voltage drops under 1V indicate internal short)

Advanced users can perform voltage rebound tests: Disconnect load after full discharge – healthy batteries should recover to 6.0V within 2 hours. Less indicates permanent capacity loss.

Voltage Management for Multi-Battery Golf Cart Systems

Series Configuration Voltage Dynamics

In 48V golf cart systems (eight 6V batteries), voltage behaves differently than single-battery applications. Each battery’s voltage adds cumulatively, but imbalances cause critical performance issues:

- Weakest battery effect: A single underperforming battery (e.g., 5.8V) drags down the entire system’s voltage

- Charge imbalance: Differences as small as 0.3V between batteries lead to progressive capacity loss

- Voltage drop calculation: Total system voltage = (Battery 1 voltage + Battery 2 voltage… + Battery 8 voltage) – Connection losses

Professional technicians use mid-point voltage testing – measuring between batteries 4 and 5 – to quickly identify imbalance issues before they escalate.

Advanced Voltage Balancing Techniques

Maintaining equal voltage across all batteries requires:

- Individual battery charging using a 6V charger on underperforming units (target 6.37V ±0.02)

- Rotational position swapping every 6 months (batteries near motor work harder)

- Equalization charging at 7.3V per battery (58.4V total) for 2-4 hours monthly

| Imbalance Level | Corrective Action | Time Required |

|---|---|---|

| 0.1-0.3V difference | Targeted charging | 2-4 hours |

| 0.3-0.5V difference | Full equalization cycle | 8 hours |

| >0.5V difference | Battery replacement | Immediate |

Note: Always disconnect series connections before individual battery work – 48V systems can deliver dangerous current.

Load Testing Multi-Battery Systems

Proper voltage evaluation under load requires:

- Two-point testing: Measure both individual batteries and total system voltage during acceleration

- Dynamic analysis: Voltage should never drop below:

- 5.8V per battery (46.4V total) on flat terrain

- 5.6V per battery (44.8V total) climbing 15° inclines

- Recovery monitoring: System voltage should return to within 3% of pre-load values within 5 minutes

Pro tip: Use a recording multimeter like the Fluke 289 to capture voltage fluctuations during actual course use.

Safety Protocols for High-Voltage Systems

When working with series-connected 6V batteries:

- Always wear 1000V-rated insulated gloves when testing live circuits

- Mark and disconnect the negative terminal first to prevent short circuits

- Use voltage-rated tools with insulated handles (minimum CAT III 600V rating)

- Install voltage monitors like the Renogy 500A Battery Monitor for real-time tracking

Remember: A 48V system can deliver over 300 amps – enough current to weld metal components accidentally.

Long-Term Voltage Optimization and Future Trends in Golf Cart Batteries

Voltage Degradation Patterns and Battery Lifecycle

Understanding voltage behavior throughout a battery’s lifespan reveals critical maintenance opportunities:

- First 100 cycles: Voltage remains stable (±0.05V) with proper charging

- 100-500 cycles: Gradual 0.1-0.2V drop under load indicates plate wear

- 500+ cycles: Increasing voltage variance between cells (>0.3V difference signals replacement need)

| Battery AgeExpected Voltage DropCorrective ActionRemaining Lifespan | |||

|---|---|---|---|

| 0-2 years | <0.1V/year | Standard maintenance | 3-5 years |

| 2-4 years | 0.2-0.3V/year | Enhanced equalization | 1-2 years |

| 4+ years | >0.5V/year | Replacement planning | <6 months |

Pro tip: Implementing voltage trend logging helps predict failure 3-6 months before catastrophic drops occur.

Cost-Benefit Analysis of Voltage Maintenance

Investing in proper voltage management yields significant returns:

- Precision chargers ($200-$500) extend battery life 2-3 years, saving $800-$1200 per set

- Voltage monitoring systems ($150-$300) prevent 80% of unexpected failures

- Professional equalization ($50/service) maintains 95% capacity through mid-life

The break-even point for advanced maintenance typically occurs at 18-24 months, making it essential for commercial fleets.

Emerging Technologies in Voltage Management

The golf cart industry is adopting:

- AI-powered chargers that analyze voltage patterns to optimize charge cycles

- Solid-state batteries with <1% voltage drop throughout discharge cycles

- Wireless voltage sensors that transmit real-time data to cloud platforms

These innovations promise to reduce voltage-related failures by up to 70% while extending usable battery life beyond 10 years.

Environmental and Safety Considerations

Proper voltage maintenance impacts sustainability:

- Every 0.1V undercharging increases sulfation by 15%, leading to 30% more battery waste

- Overvoltage (>7.5V) accelerates electrolyte decomposition, releasing harmful gases

- New voltage-regulated watering systems reduce water usage by 40%

Safety protocols now require automatic voltage disconnect systems that trigger at <5.5V or >7.2V to prevent thermal runaway.

Advanced Voltage Diagnostics and System Integration

Comprehensive Voltage Analysis Methodology

Professional technicians use a four-phase voltage analysis process to evaluate 6V golf cart batteries:

- Static Voltage Test (resting state): Measures baseline voltage after 4+ hours of inactivity

- Dynamic Load Test (under acceleration): Evaluates voltage drop during maximum current draw

- Recovery Rate Analysis: Tracks voltage rebound speed after load removal

- Comparative Cell Testing: Measures individual cell voltages in flooded batteries

This methodology identifies problems traditional testing misses – for example, a battery showing 6.3V static might reveal:

- Excessive voltage drop (>0.5V) under load indicating plate degradation

- Slow recovery (>5 minutes) suggesting sulfation buildup

- Cell voltage variance >0.15V signaling electrolyte stratification

Integration with Golf Cart Electrical Systems

Modern golf carts require voltage compatibility across multiple systems:

| System Component | Optimal Voltage Range | Interaction with 6V Batteries |

|---|---|---|

| Motor Controller | 44-52V (for 48V systems) | Low voltage triggers limp mode |

| Accessory Circuit | 11-15V (via reducer) | Voltage spikes damage electronics |

| Regenerative Braking | 54-58V maximum | Overvoltage risks battery damage |

Advanced carts now use voltage regulation modules that automatically adjust for battery age and temperature.

Specialized Scenarios and Custom Solutions

Unique operating conditions require tailored voltage management:

- Hilly terrains: Install voltage-stabilizing capacitors to handle 100A+ spikes

- Cold climates: Use battery warmers to maintain optimal 6.3-6.4V operating range

- Fleet operations: Implement centralized voltage monitoring with cloud alerts

Competition carts often employ dual-voltage systems, using separate 6V batteries for drive and accessory circuits.

Advanced Troubleshooting Flowchart

When facing voltage irregularities:

- Verify measurement accuracy (calibrate multimeter)

- Check all connections (clean and torque to 8-10 ft-lbs)

- Test individual cells (flooded batteries only)

- Evaluate charging system output

- Perform capacity test (20-hour discharge rate)

Pro tip: The “Voltage Drop Test” – measuring between battery terminal and cable end – identifies hidden resistance issues that mimic battery problems.

Mastering Voltage Optimization: Professional-Grade Strategies

System-Wide Voltage Synchronization Techniques

Optimal performance requires coordinating voltage across all components:

| Component | Target Voltage | Tolerance | Calibration Method |

|---|---|---|---|

| Battery Bank | 6.37V/cell | ±0.03V | Individual cell balancing |

| Charger Output | 7.25V/cell | ±0.05V | Digital potentiometer adjustment |

| Controller Input | 48.5V (8-cell) | ±0.5V | PWM calibration |

Advanced synchronization involves:

- Using shunt regulators to bleed excess voltage from stronger cells

- Implementing active balancing systems that transfer energy between cells

- Installing voltage reference modules for precise system-wide alignment

Performance Optimization Matrix

Maximize efficiency by matching voltage profiles to usage patterns:

| Usage Scenario | Optimal Voltage Range | Charge Strategy | Expected Cycle Life |

|---|---|---|---|

| Flat course (leisure) | 6.2-6.4V | Standard charging | 800-1000 cycles |

| Hilly terrain | 6.3-6.5V | Enhanced equalization | 600-800 cycles |

| Competition use | 6.4-6.6V | Pulse charging | 400-600 cycles |

Note: Higher voltage ranges provide more torque but reduce overall battery lifespan.

Comprehensive Risk Assessment Protocol

Professional maintenance programs include:

- Voltage differential analysis (track cell-to-cell variations over time)

- Thermal imaging scans during charging to detect hot spots

- Deep discharge simulation to predict failure points

- Correlation studies between voltage patterns and capacity loss

Critical risk thresholds:

- >0.25V difference between parallel banks

- >5% voltage drop during 10-second load test

- <3% voltage recovery after 1 hour rest

Quality Assurance Framework

Implement these validation procedures:

- Triple-point verification (measure at terminals, cables, and controller)

- Seasonal voltage profiling (adjust for temperature variations)

- Automated logging with ±0.1% accuracy sensors

- Statistical process control charts for voltage trends

Certification requires passing 7-day stress tests including:

- 100 charge/discharge cycles

- Voltage stability within 1%

- Temperature coefficient validation

Conclusion: Mastering Your 6V Golf Cart Battery Voltage

Understanding your 6V golf cart battery’s voltage is about more than just numbers – it’s the key to maximizing performance, lifespan, and reliability.

As we’ve explored, a healthy battery should maintain 6.37-6.4V when fully charged, never dropping below 6.1V during use. Through proper testing techniques, advanced maintenance strategies, and system-wide voltage management, you can prevent 80% of common battery failures before they occur.

Remember that voltage tells the complete story of your battery’s health when interpreted correctly. By implementing the professional-grade techniques covered – from precision charging to voltage trend analysis – you’ll not only extend your battery’s life by years but also ensure consistent performance round after round.

Frequently Asked Questions About 6V Golf Cart Battery Voltage

What exactly does the “6V” rating on my golf cart battery mean?

The “6V” is the nominal voltage – an average rating during normal discharge. In reality, your battery’s actual voltage fluctuates between 6.37V (fully charged) and 6.0V (50% discharged).

This rating comes from the lead-acid chemistry where each cell produces 2.1V, and three cells in series create 6.3V nominal. The voltage drops as the battery discharges due to increasing internal resistance and chemical changes in the electrolyte.

How often should I check my 6V golf cart battery’s voltage?

For optimal maintenance:

- Weekly: Check resting voltage after full charge

- Monthly: Perform under-load voltage tests

- Seasonally: Complete voltage drop analysis across all connections

Commercial operators should check voltage before each shift, as frequent deep cycling accelerates voltage degradation. Always test when you notice performance issues like reduced speed or hill-climbing ability.

Why does my battery show 7V+ when charging but drops to 6.3V afterward?

This is completely normal. During charging:

- The charger applies higher voltage (7.2-7.5V) to overcome battery resistance

- This “absorption voltage” forces current into the battery

- When charging stops, surface charge dissipates

- The voltage settles to its true “resting voltage” (6.3-6.4V)

This phenomenon is why you should always wait 4-12 hours after charging for accurate voltage readings.

Can I use a 12V charger on my 6V golf cart batteries?

Absolutely not. A 12V charger will:

- Overheat the battery, warping plates

- Boil off electrolyte at dangerous rates

- Cause terminal corrosion from excessive gassing

- Potentially lead to thermal runaway

Always use a smart 6V charger with automatic voltage detection. For multiple batteries, use a series-compatible charger or charge individually.

What voltage indicates my 6V golf cart battery needs replacement?

Watch for these warning signs:

- Resting voltage below 6.2V after full charge

- Under-load voltage drops below 5.5V during normal use

- Recovery voltage takes >2 hours to reach 6.0V after discharge

- Voltage variance >0.3V between cells in flooded batteries

When your battery consistently shows these readings despite proper charging, replacement is typically needed within 30-60 days.

How does temperature affect my 6V battery’s voltage readings?

Temperature impacts voltage significantly:

| Temperature | Voltage Adjustment |

|---|---|

| Below 32°F (0°C) | Add 0.028V per °F below 80°F |

| Above 90°F (32°C) | Subtract 0.028V per °F above 80°F |

Example: At 50°F (10°C), your 6.3V battery will read about 6.1V until warmed. Always compensate readings or wait until batteries reach room temperature for accurate assessment.

Why do my new 6V batteries show different voltages?

Minor voltage variations (up to 0.2V) in new batteries are normal due to:

- Manufacturing tolerances in plate composition

- Shipping/storage conditions affecting initial charge

- Variations in electrolyte absorption

These typically equalize after 5-10 complete charge cycles. However, differences exceeding 0.3V indicate potential defects and warrant warranty inspection.

How can I improve voltage consistency across my battery bank?

For optimal voltage balance:

- Rotate battery positions quarterly (end batteries work harder)

- Use identical cable lengths for all connections

- Clean terminals monthly with baking soda solution

- Perform equalization charges every 30-45 days

- Replace all batteries in the bank simultaneously

Professional courses often achieve <0.1V variance using active balancing systems that redistribute charge between batteries automatically.