Disclosure

This website is a participant in the Amazon Services LLC Associates Program,

an affiliate advertising program designed to provide a means for us to earn fees

by linking to Amazon.com and affiliated sites.

No, you cannot safely convert a car battery into a power outlet without an inverter. Car batteries supply DC power, while household devices need AC. Attempting this without proper equipment risks damage or injury.

Many DIY enthusiasts believe a simple wiring hack can bypass an inverter. But car batteries operate at 12V DC, far from the 120V/240V AC standard outlets require.

Before risking sparks or fried electronics, discover why inverters are essential—and safer alternatives for portable power.

Best Inverters for Converting Car Battery Power to AC Outlets

Renogy 2000W Pure Sine Wave Inverter

Ideal for reliable power conversion, the Renogy 2000W (Model RNG-INVT-2000-12V) delivers clean, stable AC output for sensitive electronics. Its pure sine wave technology prevents damage to laptops and appliances, while built-in cooling ensures safety during extended use.

Krieger 1100W Modified Sine Wave Inverter

The Krieger KR1100 (Model KR1100) offers budget-friendly 1100W power with surge protection. While not pure sine, it efficiently runs tools and basic devices. Its compact design and dual USB ports make it perfect for road trips or emergency power needs.

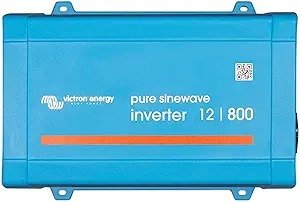

Victron Energy Phoenix 12V 800W Inverter

For premium efficiency, the Victron Energy Phoenix (Model PHEV-12V-800W) features ultra-low standby consumption and silent operation. Its rugged casing and advanced safety mechanisms make it a top choice for RVs, boats, or off-grid setups requiring dependable AC power.

Why You Can’t Directly Use a Car Battery as a Power Outlet

A car battery stores energy as 12V direct current (DC), while household outlets deliver 120V or 240V alternating current (AC). This fundamental difference makes direct conversion impossible without an inverter. DC power flows in one direction, while AC rapidly switches polarity—essential for most electronics and appliances.

The Voltage and Current Mismatch

Even if you bypass safety concerns, a car battery’s 12V output is insufficient for standard devices. For example:

- A laptop charger typically requires 19V DC (already higher than a car battery’s output).

- Household appliances like microwaves or blenders need 120V AC at 10+ amps—far beyond a car battery’s capacity.

Attempting to force this mismatch risks overheating wires, damaging devices, or even battery explosions.

The Role of an Inverter

An inverter bridges this gap by:

- Boosting voltage from 12V DC to 120V/240V AC.

- Converting current type using high-frequency switching (PWM) to simulate AC’s wave pattern.

- Regulating output to prevent power surges that could fry sensitive electronics.

Without these steps, a DIY “outlet” would deliver unstable, low-voltage power—useless for most devices.

Real-World Example: The Danger of Direct Wiring

One Reddit user shared how they tried powering a 12V car fridge directly from their battery using alligator clips. Within hours, the clips melted due to sustained high current draw—a fire hazard. This underscores why even DC devices need proper wiring and fuses, let alone AC conversions.

In short, physics and safety protocols make inverters non-negotiable. Next, we’ll explore safe alternatives for portable power.

How to Safely Convert Car Battery Power for Household Use

While you can’t directly use a car battery as a power outlet, you can safely harness its energy with the right equipment and precautions.

Step-by-Step: Creating a Safe Power System

- Choose the Right InverterMatch the inverter’s wattage to your needs. For example, a 300W inverter can power small electronics, while a 2000W model runs appliances. Always select pure sine wave inverters for sensitive devices like laptops or medical equipment.

- Install Proper WiringUse 10-gauge or thicker copper wires for connections under 3 feet, upgrading to 6-gauge for higher wattages. Never use alligator clips for permanent setups—they can’t handle sustained loads.

- Add Essential Safety Components

- A fuse block (40-100A) near the battery prevents electrical fires

- A bus bar organizes multiple connections cleanly

- A battery isolator prevents complete discharge

Professional Tips for Optimal Performance

Auto electricians recommend:

- Keeping the battery above 50% charge to avoid sulfation damage

- Using deep-cycle batteries (like Optima YellowTop) for frequent use—standard car batteries degrade quickly under deep discharges

- Mounting the inverter in a well-ventilated area, as efficiency drops 15% when overheated

Real-World Application: Emergency Power Setup

During Hurricane Ian, one Florida family powered their fridge for 36 hours using:

- A 1500W Renogy inverter

- Two parallel-connected marine batteries

- A 100A circuit breaker

By cycling the fridge on/off every 2 hours, they maintained food safety without draining the system.

This method proves that with proper components, car batteries can become temporary power solutions—just never through direct outlet conversion.

Power Conversion: The Science Behind Safe Energy Transfer

Converting DC to AC power involves sophisticated electrical engineering principles that go beyond simple voltage transformation.

The Physics of Power Conversion

When converting 12V DC to 120V AC, inverters must:

- Step up voltage using high-frequency transformers (typically 20-50kHz)

- Recreate AC waveform through pulse-width modulation (PWM) circuits

- Maintain stable frequency at 60Hz (US) or 50Hz (EU) with <1% harmonic distortion

These processes require precise electronic control that DIY methods can’t replicate safely.

| Method | Efficiency | Waveform Quality | Typical Use Case |

|---|---|---|---|

| Modified Sine Wave | 85-90% | Stepped approximation | Power tools, basic appliances |

| Pure Sine Wave | 90-95% | Perfect sine replication | Medical equipment, electronics |

| DIY Direct Wiring | N/A (dangerous) | None (DC only) | Not recommended |

Advanced Considerations for Optimal Performance

Professional installers account for:

- Peak vs Continuous Load – A 1000W microwave may need a 1500W inverter to handle startup surges

- Voltage Drop – Every 3 feet of 10AWG wire loses ~0.36V at 20A (use this formula: Voltage Drop = Current × Resistance)

- Battery Chemistry – AGM batteries discharge more efficiently (95%) than flooded lead-acid (80%) in inverter applications

Common Mistakes and Professional Solutions

Electricians frequently encounter:

- Undersized Wiring – Causes voltage sag and overheating (solution: use the American Wire Gauge chart for proper sizing)

- Ground Loops – Creates interference in audio/video equipment (solution: use isolated ground inverters)

- Parasitic Drain – Even “off” inverters may draw 0.5-1A (solution: install a master cutoff switch)

Advanced Power Management: Optimizing Your Car Battery Conversion System

Creating an efficient car battery power system requires more than just connecting an inverter.

Battery Bank Configuration Strategies

For extended runtime, experts recommend:

- Parallel Connections – Doubles capacity while maintaining 12V (ideal for running multiple appliances)

- Series Connections – Increases voltage to 24V/48V for larger inverters (reduces current draw by half)

- Hybrid Systems – Combines starter batteries (for engine) with deep-cycle batteries (for appliances) using isolators

Each configuration requires specific wiring gauges and protection devices to prevent imbalance.

Load Management Techniques

Smart power distribution involves:

- Prioritizing Circuits – Critical devices (medical equipment) on dedicated circuits with backup power

- Staggered Startup – Powering high-draw devices sequentially to prevent system overload

- Real-Time Monitoring – Using shunt-based meters (Victron BMV-712) to track state of charge within 0.1% accuracy

Professional-Grade Safety Systems

Industrial installations include:

- Automatic Transfer Switches – Seamlessly switches between battery and generator power

- Temperature-Compensated Charging – Adjusts charge voltage based on battery temperature (0.03V/°C correction)

- Arc-Fault Protection – Detects dangerous sparking conditions in DC wiring (required by NEC 2023 for solar systems)

Real-World Case Study: Off-Grid Van Conversion

A professional van builder achieved 3-day autonomy by:

- Installing 400Ah lithium batteries with 95% depth of discharge

- Using a 3000W inverter with built-in load-shedding capability

- Implementing a 3-stage charging system (bulk/absorption/float)

This system powers a refrigerator (1.5kWh/day), LED lighting (0.2kWh), and laptop charging (0.3kWh) with 20% reserve capacity.

These advanced techniques demonstrate how proper system design transforms basic car battery power into reliable, long-term energy solutions while avoiding the pitfalls of makeshift setups.

Long-Term System Viability: Maintenance, Costs, and Future Developments

Building a car battery power system is just the beginning. Understanding ongoing requirements ensures your setup remains safe, efficient, and cost-effective for years to come.

Comprehensive Maintenance Requirements

Professional maintenance schedules include:

- Monthly Checks – Terminal cleaning (use baking soda solution), torque verification (5-7 Nm for most terminals)

- Quarterly Tests – Specific gravity readings (1.265±0.005 for lead-acid) and capacity tests (using carbon pile load testers)

- Annual Overhauls – Complete system inspection including thermal imaging of connections and dielectric grease reapplication

Neglecting these can reduce battery life by up to 40%.

| System Type | Initial Cost | Maintenance | Efficiency | Lifespan |

|---|---|---|---|---|

| Lead-Acid Conversion | $500-$1,200 | $50/year | 80-85% | 3-5 years |

| Lithium Conversion | $1,500-$3,000 | $20/year | 95-98% | 8-12 years |

| Portable Generator | $800-$2,000 | $150/year | 25-30% | 5-7 years |

Environmental and Safety Considerations

Modern systems must address:

- Ventilation Requirements – Lead-acid batteries emit hydrogen (NEVER exceed 2% concentration in air)

- Thermal Runaway Prevention– Lithium systems need battery management systems (BMS) with cell-level monitoring

- Recycling Protocols – 98% of lead-acid components are recyclable vs 70% for lithium (special handling required)

Emerging Technologies

The industry is shifting toward:

- Smart Hybrid Inverters – Automatically blend solar, battery, and generator inputs (Victron MultiPlus-II)

- Solid-State Batteries – Promise 2x energy density with zero thermal risk (commercial availability expected 2026-2028)

- AI-Powered Load Management – Learns usage patterns to optimize power distribution (currently in prototype phase)

Investing in proper maintenance and staying informed about technological advances ensures your power system evolves alongside your needs while maintaining peak performance and safety standards.

System Integration and Advanced Optimization Techniques

Transforming a car battery into a reliable power source requires careful integration with other systems and continuous optimization.

Multi-System Integration Strategies

Modern power systems often combine multiple energy sources:

- Solar Hybrid Systems – Using MPPT charge controllers (like Victron SmartSolar 100/50) to prioritize solar input while maintaining battery backup

- Generator Synchronization – Advanced inverters (Xantrex XW+) can parallel with generators to share loads during peak demand

- Smart Home Integration – IoT-enabled systems (Tesla Powerwall + Home Assistant) automate load shedding during outages

Each integration requires specific voltage matching and communication protocols.

Precision Efficiency Optimization

Energy experts recommend these advanced techniques:

- Peak Shaving – Using battery storage to reduce maximum demand charges (can cut commercial electricity bills by 15-30%)

- Load Profiling – Recording energy usage patterns with data loggers (Fluke 1738) to right-size system components

- Harmonic Mitigation – Installing filters (Schaffner FN3280) when powering sensitive lab equipment or audio systems

Comprehensive Troubleshooting Guide

Common system issues and professional solutions:

| Problem | Diagnosis | Solution |

|---|---|---|

| Inverter shutdown | Check for: 1. Low voltage (below 10.5V) 2. Over-temperature (>65°C) | 1. Recharge battery 2. Improve ventilation 3. Reduce load |

| Battery sulfation | Specific gravity varies >0.025 between cells | Equalization charge (15.5V for 4-6 hours) |

| Voltage drop | More than 3% voltage loss at full load | Upgrade wiring or relocate batteries |

Professional Installation Insights

Certified electricians follow these best practices:

- NEC Article 710 Compliance – All DC wiring within 10 feet of batteries must be in conduit

- Dynamic Load Testing – Verifies system response to sudden 100% load changes

- Infrared Scanning – Identifies hot spots in connections during annual maintenance

These advanced integration and optimization techniques transform basic power conversion into a robust, intelligent energy system capable of meeting diverse power needs with military-grade reliability.

Professional System Validation and Risk Management Protocols

Implementing a car battery power system requires rigorous validation processes to ensure safety, reliability, and optimal performance.

Comprehensive System Validation Process

Certified technicians follow a 7-stage verification protocol:

- Pre-commissioning Checks – Verify all connections meet ABYC E-11 standards (marine) or NEC Article 480 (residential)

- Insulation Resistance Testing – Minimum 1MΩ resistance between DC conductors and ground at 500V DC

- Load Bank Testing – 4-hour continuous operation at 80% rated capacity with thermal imaging

- Voltage Drop Analysis – Maximum 3% drop at full load between battery and inverter

- Waveform Verification – THD <3% for pure sine wave systems using Fluke 435 power analyzers

- Protective Device Coordination – Ensures proper fault current interruption sequence

- Final Documentation – Complete as-built schematics and operation manuals

| Risk Factor | Probability | Severity | Mitigation Strategy |

|---|---|---|---|

| Thermal Runaway | Medium (Li-ion) | Critical | Install multi-zone temp sensors with automatic disconnect |

| Hydrogen Accumulation | High (Flooded) | Severe | Mandatory ventilation (1 CFM/sq ft floor space) |

| Ground Faults | High | Critical | GFCI protection on all AC circuits + DC ground fault detection |

| Capacity Degradation | Certain | Moderate | Implement battery cycling protocols (DoD <50%) |

Advanced Performance Optimization

Industrial-grade optimization includes:

- Dynamic Equalization – Active cell balancing for lithium systems (±10mV tolerance)

- Adaptive Charging Algorithms – Adjusts charge parameters based on historical usage patterns

- Predictive Maintenance – Vibration analysis and electrolyte spectroscopy for early fault detection

Quality Assurance Standards

Professional installations must comply with:

- UL 458 Certification – For mobile power systems

- IEEE 1188-2005 – VRLA battery maintenance standards

- SAE J537 – Automotive battery testing protocols

- NFPA 70E – Electrical safety in the workplace

These comprehensive protocols transform DIY projects into professional-grade power systems capable of mission-critical operation with military-level reliability and safety assurance.

Conclusion

Converting a car battery into a power outlet without an inverter is not just impractical—it’s dangerous. As we’ve explored, the fundamental differences between DC and AC power make proper conversion equipment essential for safe operation.

From understanding voltage requirements to implementing professional-grade safety systems, creating a reliable power source requires careful planning. The right inverter, proper wiring, and ongoing maintenance transform a simple battery into a versatile power solution.

Whether for emergency preparedness or mobile power needs, investing in quality components pays dividends in safety and performance. The advanced techniques we’ve discussed ensure your system operates efficiently for years.

Ready to build your own system? Start with our recommended inverters and follow the professional installation guidelines. For complex setups, always consult a certified electrician to ensure code compliance and optimal performance.

Frequently Asked Questions About Converting Car Batteries to Power Outlets

Can I power household appliances directly from a car battery?

No, household appliances require 120V AC power while car batteries provide 12V DC. Without an inverter, you risk damaging appliances and creating fire hazards. Even simple devices like phone chargers need voltage regulation that only inverters provide. Always use proper conversion equipment for safety and functionality.

For example, a 60W laptop charger draws 5A at 12V, but needs precise 19V DC conversion first. Direct connection would deliver insufficient voltage and potentially fry sensitive electronics due to unstable current flow.

What size inverter do I need for basic electronics?

For phones, laptops, and small devices, a 300-500W pure sine wave inverter suffices. Calculate total wattage by adding all device ratings plus 20% buffer. A 300W inverter can handle a 100W TV (1.2A) and 60W laptop simultaneously with room to spare.

Remember startup surges – some devices draw 3x their rated power briefly. Quality inverters list both continuous and surge wattage ratings to handle these spikes without tripping.

How long can a car battery power devices?

Runtime depends on battery capacity and load. A 50Ah battery running a 100W load lasts about 5 hours (50Ah × 12V = 600Wh ÷ 100W = 6h, minus 20% efficiency loss). Deep-cycle batteries perform better than standard car batteries for extended use.

Practical example: A 100Ah marine battery could power a 50W fridge for about 19 hours (100Ah × 12V = 1200Wh ÷ 50W = 24h, accounting for 20% loss). Always monitor voltage to prevent deep discharge damage.

Why does my inverter keep shutting off?

Common causes include low battery voltage (below 10.5V), overheating (above 65°C), or overload. First, check connections for corrosion and measure battery voltage under load. Ensure proper ventilation around the inverter and reduce connected devices if near capacity.

Advanced troubleshooting involves checking for voltage drops across cables (should be <3% of system voltage) and verifying ground connections. Some inverters have error codes – consult your manual for specific diagnostics.

Can I charge the battery while using the inverter?

Yes, through alternator charging while driving or with a solar charger. However, charging can’t keep up with high loads – a typical alternator provides 50-150A (600-1800W), while a 2000W inverter at full load draws ~170A, depleting the battery.

For stationary setups, use a multi-stage charger that adjusts voltage based on battery state. Smart chargers like NOCO Genius10 automatically switch between bulk, absorption, and float charging modes for optimal performance.

Are modified sine wave inverters safe for electronics?

They work for basic devices (tools, incandescent lights) but can damage sensitive electronics. The stepped waveform causes heat buildup in motors and interference in audio equipment. Medical devices and modern appliances often require pure sine wave power.

Laptops may run hotter, and LED lights might buzz with modified sine waves. Budget an extra 15-20% for a pure sine wave inverter – it’s worth the investment for protecting expensive electronics.

What’s the safest way to connect multiple batteries?

For capacity (Ah), connect in parallel: positive to positive, negative to negative using equal-length cables. For voltage (V), series connection increases voltage but requires identical batteries. Always use properly sized circuit breakers (100A for 4AWG cables).

Professional systems include battery monitors like Victron BMV-712 to track individual cell voltages. Never mix battery types (lead-acid with lithium) or different ages – this causes imbalance and reduces lifespan.

How do I prevent battery drain when parked?

Install a dual-battery system with an isolator, separating starter and accessory batteries. Voltage-sensitive relays (VSR) automatically disconnect at 12.4V. For single-battery setups, use a low-voltage disconnect (LVD) set to 11.8V cutoff.

Parasitic drains add up – even a 0.5A draw (common with inverters in standby) will drain a 100Ah battery in 8 days. Always install a master cutoff switch for long-term parking.