Disclosure

This website is a participant in the Amazon Services LLC Associates Program,

an affiliate advertising program designed to provide a means for us to earn fees

by linking to Amazon.com and affiliated sites.

Batteries produce direct current (DC) voltage, a steady flow of electrical energy in one direction. Unlike alternating current (AC), DC voltage remains constant, making it ideal for portable devices.

You might assume all power sources work the same, but batteries differ from wall outlets. While your home uses AC, your phone relies on DC—here’s why.

Best Multimeters for Measuring Battery Voltage

Fluke 87V Digital Multimeter

The Fluke 87V is a top-tier multimeter for professionals, offering high accuracy (±0.05%) and True RMS for precise DC voltage readings. Its rugged design and CAT IV safety rating make it ideal for automotive and industrial battery testing.

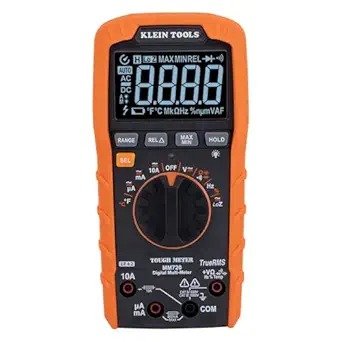

Klein Tools MM720 Auto-Ranging Multimeter

The Klein Tools MM720 is a budget-friendly yet reliable choice, featuring auto-ranging for hassle-free voltage checks. Its backlit display and durable build make it perfect for DIYers testing car batteries or household DC power sources.

Innova 3340 Automotive Digital Multimeter

Designed for car enthusiasts, the Innova 3340 includes specialized modes for 12V/24V systems. Its easy-to-read screen and built-in thermometer help diagnose battery health, making it a great tool for troubleshooting vehicle electrical issues.

How Batteries Generate Direct Current (DC) Voltage

Batteries produce direct current (DC) voltage through electrochemical reactions inside their cells. Unlike alternating current (AC), which periodically reverses direction, DC flows steadily in one direction, making it ideal for powering electronics. This happens because batteries convert chemical energy into electrical energy in a controlled, one-way process.

The Science Behind Battery Voltage

Every battery contains three key components: an anode (negative terminal), a cathode (positive terminal), and an electrolyte.

When a circuit is completed (e.g., by turning on a device), electrons flow from the anode to the cathode, creating an electrical current. The voltage produced depends on the battery’s chemistry:

- Alkaline batteries (AA, AAA): Typically produce 1.5V per cell due to the zinc-manganese dioxide reaction.

- Lithium-ion batteries: Deliver 3.6V–3.7V per cell, thanks to their high-energy lithium-cobalt oxide chemistry.

- Lead-acid batteries (car batteries): Generate 2.1V per cell, with six cells combined to produce 12.6V when fully charged.

Why DC Voltage Matters in Real-World Applications

DC voltage is crucial for devices requiring stable, low-power energy. For example:

- Smartphones: Use lithium-ion batteries (3.7V) because DC provides consistent power without damaging sensitive circuits.

- Flashlights: Rely on alkaline batteries (1.5V) for steady light output without flickering.

- Electric vehicles: Use high-voltage DC battery packs (400V–800V) for efficient energy storage and motor performance.

Common Misconceptions About Battery Voltage

A frequent mistake is assuming all batteries provide the same voltage. In reality, voltage varies by chemistry and design. For instance, stacking cells in series (like in a 9V battery) increases voltage, while parallel configurations boost capacity. Additionally, voltage drops as a battery discharges, which is why devices may malfunction before the battery is “dead.

How to Measure Battery Voltage Accurately

Proper voltage measurement is essential for diagnosing battery health and ensuring optimal device performance. Using the wrong technique can give misleading readings that might cause you to replace good batteries or overlook failing ones. Follow this professional approach for reliable results.

Step-by-Step Voltage Measurement Process

- Select the right multimeter: Use a digital multimeter (DMM) with DC voltage capability. Auto-ranging models like the Fluke 87V simplify the process by automatically selecting the proper range.

- Prepare the battery: For accurate readings, measure batteries at room temperature (20-25°C). Cold batteries can show up to 20% lower voltage temporarily.

- Set up your multimeter:

- Turn the dial to DC voltage (V⎓)

- For car batteries, select 20V range

- For small batteries (AA/AAA), use 2V or 2000mV range

- Connect the probes properly:

- Red probe to positive (+) terminal

- Black probe to negative (-) terminal

- Maintain solid contact for 3-5 seconds

Interpreting Your Voltage Readings

Understanding what your measurements mean is crucial:

| Battery Type | Healthy Voltage | Needs Recharge | Replace Soon |

|---|---|---|---|

| 12V Car Battery | 12.6-12.8V | 12.0-12.5V | Below 11.9V |

| AA Alkaline | 1.5-1.6V | 1.2-1.49V | Below 1.2V |

| Li-ion (Smartphone) | 3.7-4.2V | 3.4-3.69V | Below 3.4V |

Professional Measurement Tips

- Measure under load: For car batteries, check voltage while cranking the engine (should stay above 9.6V)

- Watch for voltage sag: If voltage drops significantly when connecting probes, the battery may have high internal resistance

- Check multiple cells: In multi-cell batteries (like 9V), measure individual cells to identify weak ones

Remember that voltage alone doesn’t tell the whole story – a battery showing proper voltage might still have reduced capacity. For complete diagnosis, combine voltage tests with load testing or capacity measurements.

Battery Voltage Variations and Performance Factors

Battery voltage isn’t constant – it fluctuates based on multiple technical factors that affect performance and lifespan. Professional technicians understand these variations to accurately assess battery health and predict remaining useful life.

Key Factors Affecting Battery Voltage Output

Several scientific principles govern how batteries maintain their voltage:

- Temperature effects: Chemical reactions slow in cold temperatures, reducing voltage by 0.3-0.5V per 10°C drop below 20°C

- Load current: Higher current draws cause greater voltage drop due to internal resistance (Ohm’s Law: V=IR)

- State of charge: Voltage decreases predictably as stored energy depletes (see discharge curve table below)

- Age degradation: Electrode corrosion increases internal resistance, causing voltage to sag under load

Battery Discharge Curves by Chemistry

| Chemistry | Initial Voltage | Nominal Voltage | End Voltage | Discharge Curve Shape |

|---|---|---|---|---|

| Lead-Acid | 12.8V | 12.6V | 10.5V | Gradual linear decline |

| Li-ion | 4.2V | 3.7V | 3.0V | Flat plateau then steep drop |

| NiMH | 1.4V | 1.2V | 1.0V | Steady gradual decline |

Advanced Voltage Analysis Techniques

Professional battery testing goes beyond simple voltage measurements:

- Open Circuit Voltage (OCV) testing: Measure after 24+ hours rest to eliminate surface charge effects

- Dynamic voltage analysis: Monitor voltage response to pulsed loads to assess internal resistance

- Voltage recovery testing: Time how quickly voltage rebounds after load removal (indicates sulfation in lead-acid)

- Mid-point voltage monitoring: Track voltage at 50% discharge for most accurate state-of-charge estimation

Common Voltage Interpretation Mistakes

Avoid these frequent errors when working with battery voltage:

- Measuring too soon: Testing immediately after charging shows artificially high “surface charge” voltage

- Ignoring temperature: Not compensating for cold weather readings leads to false “weak battery” diagnoses

- Overlooking load conditions: A battery showing 12.6V OCV might drop to 9V under cranking load if failing

- Mixing chemistries: Applying lead-acid voltage standards to lithium batteries causes incorrect assessments

Battery Voltage Safety and Handling Best Practices

Working with battery voltage requires careful attention to safety protocols and proper handling techniques. Different battery chemistries present unique hazards that demand specific precautions to prevent accidents, damage, or injuries.

Critical Safety Considerations by Battery Type

| Battery Chemistry | Primary Hazards | Maximum Safe Voltage | Special Precautions |

|---|---|---|---|

| Lead-Acid | Acid burns, hydrogen gas | 15V (12V systems) | Ventilate charging areas, wear acid-resistant gloves |

| Lithium-Ion | Thermal runaway, fire | 4.25V per cell | Use protective circuits, avoid mechanical damage |

| NiMH | Overheating, leakage | 1.6V per cell | Monitor temperature during charging |

Professional Handling Procedures

- Personal Protective Equipment (PPE):

- Safety glasses with side shields for all battery work

- Insulated gloves when handling high-voltage (>50V) systems

- Face shield when working with large lead-acid batteries

- Safe Measurement Techniques:

- Always measure voltage before current to prevent meter damage

- Use fused test leads for automotive battery testing

- Keep one hand in pocket when working on live circuits

Troubleshooting Voltage-Related Issues

When encountering abnormal voltage readings:

- Low voltage after charging: Check for parasitic drains (should be <50mA in vehicles) or sulfated plates in lead-acid

- Voltage spikes: May indicate regulator failure in charging systems – immediately disconnect and diagnose

- Unstable readings: Often caused by poor connections – clean terminals and retighten to specified torque

Industry Standards and Compliance

Professional battery systems should comply with:

- IEEE 1187 for stationary lead-acid installations

- UL 2054 for lithium battery safety certification

- IEC 62133 for portable battery safety requirements

- SAE J537 for automotive battery testing standards

Always store batteries at 40-60% charge in temperature-controlled environments (15-25°C) to maximize lifespan. For lithium batteries, implement a battery management system (BMS) that monitors individual cell voltages to prevent dangerous imbalances.

Optimizing Battery Performance Through Voltage Management

Advanced voltage management techniques can significantly extend battery life and improve performance. Understanding these methods allows users to maximize their battery investments while maintaining safety and reliability.

Voltage Thresholds for Maximum Battery Lifespan

| Battery Type | Ideal Storage Voltage | Optimal Charge Voltage | Discharge Cutoff | Cycle Life at Optimal Voltage |

|---|---|---|---|---|

| Li-ion (3.7V) | 3.8V | 4.1V (instead of 4.2V) | 3.0V | 1200+ cycles |

| Lead-Acid (12V) | 12.4V | 14.4V (absorption) | 10.8V | 500-800 cycles |

| NiMH (1.2V) | 1.25V | 1.45V | 1.0V | 300-500 cycles |

Advanced Voltage Regulation Techniques

- Smart Charging Algorithms:

- CC-CV (Constant Current-Constant Voltage) for lithium batteries

- Three-stage charging (bulk/absorption/float) for lead-acid

- Pulse charging for NiMH to prevent voltage depression

- Voltage Compensation Methods:

- Temperature compensation (-3mV/°C/cell for lead-acid)

- Line loss compensation for long cable runs

- Load-dependent voltage adjustment

Emerging Technologies in Voltage Management

The battery industry is developing innovative voltage control solutions:

- AI-powered voltage prediction: Machine learning algorithms analyze voltage patterns to predict failures

- Self-regulating batteries: Smart materials that automatically adjust internal resistance

- Quantum voltage sensors: Ultra-precise measurement at the atomic level

- Solid-state voltage regulation: Eliminates need for external BMS in some applications

Economic and Environmental Considerations

Proper voltage management impacts both costs and sustainability:

- Operating Li-ion at 4.1V instead of 4.2V increases lifespan by 40% with only 10% capacity reduction

- Maintaining lead-acid batteries at correct float voltage prevents water loss and reduces maintenance

- Voltage-matched battery pairing in solar systems improves efficiency by 5-8%

- Precise voltage control reduces energy waste and extends replacement intervals

Future battery designs are focusing on flatter voltage curves and wider operating ranges to simplify management while maintaining performance.

These developments will make voltage optimization more accessible to non-technical users while improving overall system reliability.

Battery Voltage in Complex Electrical Systems

Modern electrical systems often integrate multiple battery banks with different voltage requirements, creating unique challenges for system designers and maintenance technicians. Understanding these interactions is crucial for reliable operation.

Voltage Matching and System Integration

When combining multiple batteries or connecting to electrical systems:

- Series connections: Voltages add while capacity remains constant (e.g., two 12V 100Ah batteries in series = 24V 100Ah)

- Parallel connections: Voltage stays the same while capacities add (e.g., two 12V 100Ah batteries in parallel = 12V 200Ah)

- Mixed configurations: Series-parallel arrangements must maintain identical voltages and states of charge across all strings

Voltage Conversion and Regulation Techniques

Different systems require specialized voltage management approaches:

| Application | Voltage Challenge | Solution | Efficiency |

|---|---|---|---|

| Solar Power Systems | Variable input voltage | MPPT charge controllers | 92-98% |

| EV Conversions | High-voltage DC to 12V | DC-DC converters | 85-93% |

| Marine Systems | Voltage drop over long runs | 24V or 48V systems | 7-12% improvement |

Advanced System Monitoring

Professional installations implement comprehensive voltage monitoring:

- Individual cell monitoring: Critical for lithium battery banks to prevent dangerous imbalances

- Voltage logging: Tracks long-term trends to predict failures before they occur

- Automated alerts: Notifies when voltages exceed safe operating parameters

- Load-dependent compensation: Adjusts voltage based on current draw to maintain stability

Troubleshooting Complex Voltage Issues

Common problems in multi-battery systems include:

- Voltage imbalance: Caused by uneven aging, temperature variations, or connection resistance

- Ground loops: Create false voltage readings and measurement errors

- Transient spikes: Inductive loads can generate voltage spikes exceeding 100V in 12V systems

- Voltage creep: Gradual increase in system voltage indicating failing regulation

For mission-critical applications, consider redundant voltage monitoring systems and automatic isolation switches that trigger when voltages exceed safe thresholds. These systems typically add 5-15% to installation costs but prevent catastrophic failures.

Strategic Battery Voltage Management for Long-Term System Reliability

Implementing a comprehensive voltage management strategy is critical for maximizing battery lifespan and system performance. This final section synthesizes key concepts into actionable best practices for professional applications.

Comprehensive Voltage Monitoring Framework

An effective monitoring system should track these critical voltage parameters:

| Parameter | Measurement Frequency | Acceptable Variance | Corrective Action Threshold |

|---|---|---|---|

| Float Voltage | Continuous | ±1% of setpoint | ±2% sustained variance |

| Cell Balance | Daily (Li-ion) | <50mV difference | >100mV difference |

| Load Voltage Sag | Per operation cycle | <10% drop | >15% drop |

| Recovery Time | Weekly | <30 seconds to 90% | >60 seconds |

Advanced Predictive Maintenance Techniques

- Voltage Trend Analysis:

- Track resting voltage decline rates to predict end-of-life

- Compare charge/discharge voltage differentials to detect increasing internal resistance

- Dynamic Response Testing:

- Analyze voltage response to controlled load pulses

- Measure voltage recovery time constants

System-Wide Voltage Optimization

For complex installations:

- Voltage zoning: Segment systems by voltage requirements to minimize conversion losses

- Adaptive charging: Adjust charge voltage based on usage patterns and temperature

- Load prioritization: Automatically shed non-critical loads when voltages drop below thresholds

Quality Assurance Protocols

Implement these validation procedures:

- Annual capacity testing with synchronized voltage logging

- Infrared thermography during high-voltage operations

- Periodic torque checks on all high-current connections

- Dielectric withstand testing for high-voltage battery packs

For mission-critical systems, consider implementing redundant voltage monitoring paths with automatic cross-verification. This level of protection typically adds 10-20% to system costs but can prevent 90% of voltage-related failures.

The most advanced systems now incorporate machine learning algorithms that analyze historical voltage patterns to predict failures weeks in advance, allowing for planned maintenance rather than emergency repairs.

Conclusion

Understanding battery voltage is fundamental to working with any electrical system. We’ve explored how different battery chemistries produce specific voltage outputs and why DC voltage dominates battery-powered applications.

Proper voltage measurement techniques, safety protocols, and system integration methods ensure optimal performance. Advanced monitoring and predictive maintenance can significantly extend battery lifespan while preventing failures.

From basic AA batteries to complex multi-bank systems, voltage management remains the key to reliability. The strategies covered here apply equally to consumer electronics and industrial power systems.

Put this knowledge into practice by regularly checking your batteries’ voltage and implementing appropriate maintenance routines. Your devices – and wallet – will thank you for the extended battery life and reliable performance.

Frequently Asked Questions About Battery Voltage

What exactly is battery voltage and how is it created?

Battery voltage represents the electrical potential difference between its terminals, created through electrochemical reactions. When chemicals like lithium or lead interact with electrolytes, they release electrons that flow from negative to positive terminals when connected to a circuit.

Different materials produce different voltages – lithium yields 3.7V per cell while alkaline produces 1.5V. This potential difference remains stable until the chemical reactions slow as the battery discharges.

Why do batteries produce DC voltage instead of AC?

Batteries generate DC because their chemical reactions create a constant, one-way electron flow. The anode consistently releases electrons while the cathode absorbs them, maintaining unidirectional current unlike AC’s alternating flow.

DC’s steady voltage better suits electronic devices requiring stable power. Converting battery DC to AC would waste energy and add complexity to simple portable devices.

How can I accurately measure my car battery’s voltage?

Use a digital multimeter set to 20V DC range. Connect red probe to positive terminal and black to negative with engine off. A healthy 12V battery should read 12.6-12.8V when fully charged.

For most accurate results, measure after the car sits overnight. Avoid testing immediately after driving as surface charge can show artificially high readings.

Why does my battery show good voltage but won’t start my car?

Voltage alone doesn’t indicate capacity. A battery might show 12V but lack sufficient current due to sulfation or plate damage. Test under load – if voltage drops below 9.6V when cranking, replace the battery.

This condition often occurs in older batteries where chemical degradation reduces active material despite maintaining surface voltage.

How does temperature affect battery voltage?

Cold temperatures slow chemical reactions, temporarily reducing voltage. A lead-acid battery at -18°C may show 0.3-0.5V lower than at 25°C. Lithium batteries experience similar but less severe drops.

High temperatures increase voltage slightly but accelerate permanent damage. Always compensate charging voltage by -3mV/°C/cell for lead-acid in hot environments.

Can I mix different voltage batteries in a system?

Never directly connect batteries of different voltages in series or parallel. Mismatched voltages cause dangerous current flows as higher voltage batteries try to charge lower ones, potentially leading to overheating or explosions.

For mixed-voltage systems, use appropriate DC-DC converters between different voltage sections to maintain safety and proper charging.

How often should I check my solar battery bank’s voltage?

Check individual cell voltages weekly in lithium systems and monthly for lead-acid. More frequent monitoring (even daily) is recommended during extreme temperatures or heavy usage periods.

Install permanent voltage monitors with alarms for critical systems. Voltage imbalances over 50mV between cells indicate developing problems needing attention.

Why does my new lithium battery’s voltage seem too high?

Fresh lithium batteries often ship at 3.8-3.9V per cell (30-40% charge) for storage safety. When fully charged to 4.2V, they may seem excessively high compared to other chemistries.

This is normal – lithium cells operate optimally between 3.0-4.2V. Never charge beyond the manufacturer’s specified maximum voltage.