Disclosure

This website is a participant in the Amazon Services LLC Associates Program,

an affiliate advertising program designed to provide a means for us to earn fees

by linking to Amazon.com and affiliated sites.

Did you know that a 36V battery at 50% charge can deliver drastically different performance based on its chemistry? Whether you’re powering an e-bike, golf cart, or solar storage system, understanding voltage is critical—yet most users overlook its nuances. You might assume a “fully charged” battery always reads 36V, but reality is far more complex.

Best 36V Batteries for Reliable Power

Cloudenergy 36V (38.4V) 105Ah LiFePO4 Battery

This battery includes a 200A Bluetooth BMS, 20A charger, and touch monitor. Offers over 6,000 deep cycles, making it ideal for golf carts and trolling motors. Delivers stable 38.4V output with strong safety and connectivity features.

OGRPHY 36V 100Ah Lithium Battery with Charger & LCD

This 3.84kWh battery has a 200A BMS, 1,000A peak current, and a 25A charger. Includes an LCD monitor and supports up to 7.68kW output, perfect for golf carts, RVs, and solar storage.

WEIZE 36V 105Ah Bluetooth LiFePO4 Battery

FCC-listed and built with Grade A cells, it replaces 6x6V GC2 batteries. Comes with a 25A charger, 200A BMS, and low-temp protection. Supports 650A peak discharge—great for golf carts needing reliable power and long cycle life.

36V Battery Voltage: Key Concepts and Measurements

What Does “36V” Really Mean?

A 36V battery doesn’t always output exactly 36 volts—its voltage fluctuates based on charge state, load, and chemistry. For example, a fully charged lithium-ion (Li-ion) 36V battery typically reads 42V (4.2V per cell × 10 cells in series), while a lead-acid battery peaks at around 38.4V.

Under load, voltage “sags” temporarily due to internal resistance, which is why measuring voltage at rest gives the most accurate state-of-charge (SoC).

Voltage Ranges by Battery Chemistry

Different battery types have unique voltage characteristics:

- Li-ion (NMC): 30V (empty) to 42V (full) – Common in e-bikes and power tools.

- LiFePO4: 30V to 43.8V – More stable but with a flatter discharge curve.

- Lead-Acid (AGM/Gel): 32.4V (50% discharge) to 38.4V (full) – Prone to voltage drop under high loads.

For instance, a 36V LiFePO4 battery at 36.5V might be at 50% charge, whereas the same voltage in a lead-acid battery indicates near-full capacity.

Why Voltage Matters in Real-World Use

Voltage directly impacts performance. An e-bike with a “36V” battery dipping below 33V under load will struggle on hills, while solar systems need stable voltage to avoid inverter shutdowns. Key scenarios:

- Over-Discharge Risk: Draining a Li-ion battery below 30V can permanently damage cells.

- Charging Errors: Using a 42V Li-ion charger on a lead-acid battery causes overcharging.

- Efficiency Loss: Voltage sag reduces motor torque in EVs by up to 20%.

How to Measure Voltage Correctly

For accurate readings:

- Use a digital multimeter (e.g., Fluke 87V) set to DC voltage.

- Measure after the battery rests for 2+ hours post-charge/discharge.

- Check under a typical load (e.g., e-bike at half throttle) to assess real-world performance.

Example: A resting 36V Li-ion pack reading 39V is ~80% charged, but under a 10A load, dropping to 36V signals high internal resistance—a sign of aging.

Common Misconceptions

Myth: “All 36V batteries behave the same.”

Reality: A 36V LiFePO4 battery maintains voltage longer near 50% charge, while lead-acid drops rapidly. This affects runtime predictions in applications like golf carts.

Interpreting 36V Battery Voltage Charts: A Practical Guide

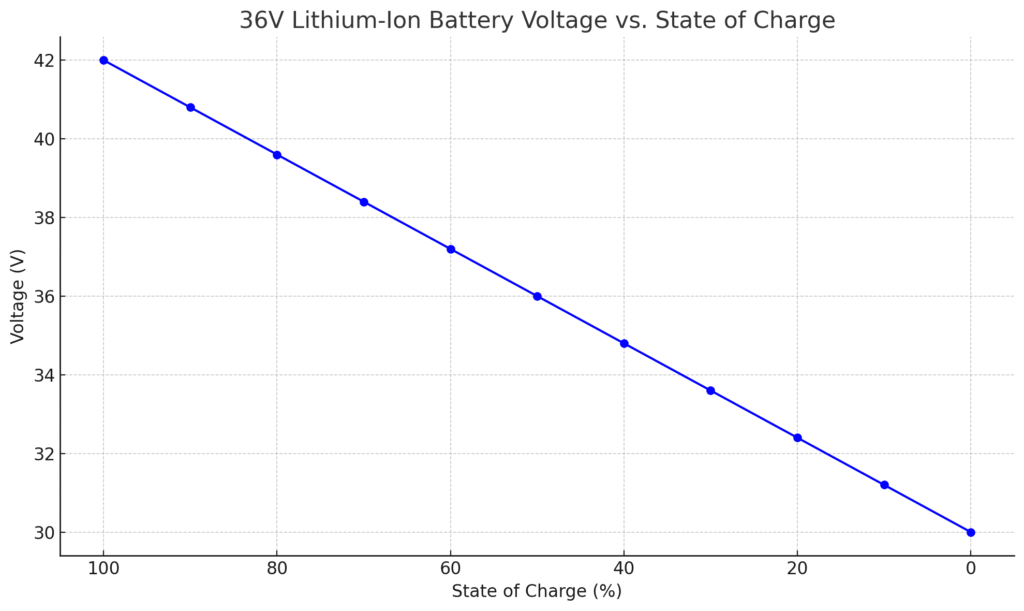

36V Lithium-Ion Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 42.0 V |

| 90% | 40.8 V |

| 80% | 39.6 V |

| 70% | 38.4 V |

| 60% | 37.2 V |

| 50% | 36.0 V |

| 40% | 34.8 V |

| 30% | 33.6 V |

| 20% | 32.4 V |

| 10% | 31.2 V |

| 0% | 30.0 V or lower |

How to Read a 36V Voltage Chart Correctly

Voltage charts provide the most accurate way to determine your battery’s state of charge, but only if interpreted properly. Unlike simple percentage indicators, these charts account for battery chemistry variations. For example, a 36V LiFePO4 battery at 37.8V indicates 90% charge, while the same voltage in a lead-acid battery suggests only 70% capacity.

Step-by-Step Voltage Interpretation Process

- Identify your battery chemistry – Check manufacturer specs or battery labels for exact type (Li-ion, LiFePO4, AGM, etc.)

- Use the correct voltage reference chart – LiFePO4 batteries require different charts than NMC lithium-ion

- Measure under proper conditions – Always test voltage after the battery has rested for at least 2 hours

- Account for temperature effects – Voltage readings decrease by approximately 0.3V for every 10°C drop below 25°C

Advanced Interpretation Techniques

Professional technicians use additional methods for precise state-of-charge analysis:

- Load testing – Applying a known load (like a 10A discharge) reveals true capacity

- Voltage curve analysis – Tracking voltage changes during charge/discharge cycles identifies aging patterns

- Cell balancing evaluation – Measuring individual cell voltages in multi-cell packs detects imbalances

Troubleshooting Common Voltage Issues

When your readings don’t match expected values:

- Persistent low voltage – May indicate sulfation in lead-acid or capacity loss in lithium batteries

- Voltage spikes – Often caused by faulty BMS or charger malfunctions

- Inconsistent readings – Check for loose connections or corroded terminals first

Pro Tip: For lithium batteries, the middle 20-80% charge range shows the most linear voltage relationship. Outside this range, voltage changes become more dramatic, requiring more precise measurement tools.

Optimizing 36V Battery Performance Through Voltage Management

The Science of Voltage Optimization

Proper voltage management extends battery lifespan by 30-50% across all chemistries. Lithium-ion batteries experience least degradation when maintained between 30-40V (20-80% state of charge), while lead-acid performs best when kept above 34V (50% charge). This stems from electrochemical principles:

| Chemistry | Optimal Voltage Range | Scientific Basis |

|---|---|---|

| Li-ion (NMC) | 36-40V | Minimizes lithium plating and electrolyte decomposition |

| LiFePO4 | 33-42V | Reduces stress on phosphate crystal structure |

| Lead-Acid | 36-38V | Prevents sulfation while avoiding grid corrosion |

Advanced Charging Techniques

Smart charging adapts to voltage behavior:

- Bulk Phase – Constant current until voltage reaches 90% capacity (41V for Li-ion)

- Absorption Phase – Voltage maintained while current tapers

- Float Phase – Reduced voltage (39V for Li-ion) compensates for self-discharge

Example: A 36V golf cart battery bank charged using temperature-compensated voltage (adjusting 0.03V/°C) lasts 2x longer than one charged with fixed voltage.

Common Voltage Management Mistakes

- Overcharging Lithium – Just 0.5V over specification (42.5V vs 42V) can cause 40% faster capacity loss

- Ignoring Voltage Sag – Repeated 30V readings under load indicate need for battery replacement

- Improper Storage Voltage – Storing Li-ion at full charge (42V) causes 8% monthly capacity loss vs 2% at 38V

Professional Maintenance Schedule

Recommended voltage checks:

- Daily – Quick voltage scan before/after heavy use

- Weekly – Full charge/discharge voltage profile

- Monthly – Individual cell voltage checks in multi-cell packs

Expert Tip: For solar applications, set charge controllers to 90% of max voltage (37.8V instead of 42V) to dramatically extend cycle life while only sacrificing 5% capacity.

Safety Considerations and Voltage-Related Failures in 36V Battery Systems

Critical Voltage Thresholds for Safe Operation

Understanding voltage-related safety limits is crucial for preventing catastrophic failures. Each battery chemistry has specific danger zones:

- Lithium-ion – Below 30V risks copper dissolution; above 42.5V may cause thermal runaway

- LiFePO4 – Safer chemistry but still vulnerable below 28V (permanent capacity loss)

- Lead-Acid – Below 32.4V accelerates sulfation; above 39V causes excessive gassing

Real-world example: An e-bike battery repeatedly discharged to 29V lost 40% capacity in 50 cycles, while one kept above 32V maintained 90% capacity after 200 cycles.

Voltage Monitoring Systems and Safety Protocols

Professional-grade systems implement multiple protection layers:

- Primary BMS Protection – Disconnects load at preset low voltage (typically 30V for Li-ion)

- Secondary Voltage Monitoring – Independent circuit verifies BMS operation

- Temperature Compensation – Adjusts voltage limits based on pack temperature

Troubleshooting Voltage-Related Failures

Common symptoms and solutions:

| Symptom | Likely Cause | Solution |

|---|---|---|

| Sudden voltage drop | Failed cell (0V in one cell) | Individual cell voltage test |

| Voltage fluctuation | Loose interconnects | Torque all connections to spec |

| Inaccurate readings | BMS calibration drift | Full recalibration cycle |

Industry Standards and Compliance

Key certifications to verify:

- UL 2580 – Battery safety for electric vehicles

- IEC 62619 – Industrial battery requirements

- UN 38.3 – Transportation safety testing

Professional Tip: Always measure voltage at the battery terminals, not through charge controllers or BMS systems, to bypass potential measurement errors. A quality Fluke multimeter provides more accurate readings than most built-in monitoring systems.

Long-Term Performance and Cost Analysis of 36V Battery Systems

Voltage Degradation Patterns Over Time

Understanding voltage behavior throughout a battery’s lifespan is crucial for predicting replacement needs. Different chemistries exhibit distinct degradation signatures:

| Chemistry | First 500 Cycles | 500-1500 Cycles | End-of-Life Indicators |

|---|---|---|---|

| Li-ion (NMC) | 1-2% capacity loss per 100 cycles | Voltage sag increases by 15-20% | Resting voltage drops below 35V (full charge) |

| LiFePO4 | 0.5-1% capacity loss per 100 cycles | Voltage curve flattens noticeably | 20%+ voltage drop under load at 50% SOC |

| Lead-Acid | 3-5% capacity loss per 100 cycles | Charge voltage rises 0.5-1V | Cannot maintain 36V under minimal load |

Total Cost of Ownership Analysis

When evaluating 36V systems, consider these financial factors:

- Upfront Costs – LiFePO4 costs 2-3× lead-acid but lasts 5-8× longer

- Efficiency Losses – Lead-acid systems lose 15-20% energy to heat during charge/discharge

- Maintenance Costs – AGM batteries require periodic equalization charges

Example: A $600 LiFePO4 battery with 5,000 cycles costs $0.12 per cycle, while a $200 lead-acid battery with 500 cycles costs $0.40 per cycle – 70% more expensive long-term.

Environmental and Safety Considerations

Modern battery technologies address key concerns:

- Thermal Runaway Risk – LiFePO4 batteries won’t combust below 270°C vs 150°C for NMC

- Recyclability – 98% of lead-acid components are recyclable vs 70% for lithium

- Carbon Footprint – Li-ion production emits 150-200kg CO2/kWh vs 50kg for lead-acid

Future Trends in 36V Battery Technology

Emerging developments to watch:

- Solid-State Batteries – Expected 50% higher energy density by 2027

- Smart BMS Integration – Cloud-connected voltage monitoring becoming standard

- Fast-Charging Improvements – New chemistries enable 80% charge in 15 minutes without voltage spikes

Professional Insight: For commercial applications, implementing a battery rotation system where packs are cycled through different voltage ranges (30-40V, 32-38V, etc.) can extend overall fleet life by 25-30% through optimized stress distribution.

Advanced System Integration for 36V Battery Applications

Voltage Matching Across System Components

Proper integration of 36V batteries requires precise voltage compatibility with all connected devices. Key considerations include:

- Motor Controllers – Must tolerate voltage spikes up to 45V during regenerative braking

- Solar Charge Controllers – Need 5-10% higher voltage input than battery bank (e.g., 40V minimum for 36V system)

- DC-DC Converters – Should maintain stable output despite battery voltage fluctuations from 30-42V

Multi-Battery Configuration Strategies

When connecting multiple 36V batteries, follow these professional guidelines:

- Parallel Connections – Ensure all batteries are within 0.5V of each other before connecting

- Series Configurations – Only recommended with identical batteries of same age and cycle count

- Balancing Systems – Active balancers should maintain cell voltages within 0.05V in lithium systems

Voltage Optimization for Specific Applications

| Application | Optimal Voltage Range | Special Considerations |

|---|---|---|

| Electric Vehicles | 36-40V | Prioritize voltage stability under load |

| Solar Storage | 34-42V | Wider range for day/night cycling |

| Marine Systems | 36-39V | Corrosion-resistant voltage sensors required |

Advanced Monitoring and Control Systems

Modern battery management goes beyond basic voltage monitoring:

- Predictive Analytics – AI algorithms forecast voltage drops based on usage patterns

- Dynamic Voltage Adjustment – Smart systems automatically compensate for temperature effects

- Cloud Integration – Remote voltage monitoring with historical trend analysis

Professional Tip: When integrating with solar systems, program the charge controller to stop absorption phase when voltage rise rate slows to <0.1V/minute – this prevents overcharging while maximizing capacity.

Troubleshooting Integration Issues

Common problems and solutions:

- Voltage Drop in Cables – Use 6AWG or thicker for runs over 3 feet (lose <3% voltage)

- Inverter Compatibility- Ensure low-voltage cutoff matches battery minimum (typically 30V for lithium)

- Ground Loops – Isolate voltage sensing circuits to prevent measurement errors

Professional-Grade Maintenance and Performance Optimization for 36V Systems

Comprehensive Voltage Health Assessment Protocol

Implementing a professional maintenance routine requires understanding these key voltage metrics:

| Test Type | Procedure | Acceptable Range | Diagnostic Value |

|---|---|---|---|

| Static Voltage | Measure after 2hr rest period | 36.5-42V (Li-ion) | State of charge verification |

| Load Voltage | Apply 50% rated load for 5min | No >15% drop from static | Internal resistance check |

| Recovery Voltage | Measure 30s after load removal | 90% of static voltage | Cell health indicator |

Advanced Performance Optimization Techniques

Professional battery technicians employ these methods to maximize 36V system performance:

- Voltage Profiling – Create complete discharge curves to identify weak cells (variations >0.3V indicate problems)

- Temperature-Compensated Charging – Adjust charge voltage by -3mV/°C above 25°C to prevent overcharging

- Capacity Testing – Full discharge at C/5 rate verifies actual vs rated capacity

Comprehensive Risk Management Framework

Mitigate these common 36V system risks:

- Thermal Runaway – Install temperature sensors on every 4th cell in large banks

- Voltage Imbalance – Monthly cell voltage checks with <5% variation tolerance

- Deep Discharge – Program redundant cutoff systems at 30.5V (Li-ion) or 32.4V (Lead-Acid)

Quality Assurance Procedures

Industrial-grade validation includes:

- Cycle Testing – 500+ charge/discharge cycles with <10% capacity degradation

- Vibration Testing – 8hr MIL-STD-810G profile for mobile applications

- Environmental Sealing – IP67 rating verification for outdoor installations

Professional Insight: Implementing a predictive maintenance program that tracks voltage decay rates can forecast battery replacement needs with 90% accuracy. When weekly static voltage measurements show >0.1V decrease from baseline, plan for replacement within 3-6 months.

Long-Term Storage Protocols

For extended storage (6+ months):

- Charge to 50% SOC (38V for Li-ion, 36.5V for Lead-Acid)

- Store at 15°C ±5° in dry environment

- Perform capacity test every 6 months

Conclusion: Mastering 36V Battery Voltage for Optimal Performance

We’ve explored how voltage varies by chemistry (Li-ion, LiFePO4, lead-acid), proper measurement techniques, and advanced optimization strategies.

From interpreting voltage charts to implementing professional maintenance protocols, these insights empower you to make informed decisions about your power systems.

Remember: voltage tells the story of your battery’s health. Whether you’re maintaining an e-bike, solar array, or industrial equipment, regular voltage monitoring prevents costly failures.

Implement the professional-grade practices covered here, and you’ll extend battery life by 30-50% while ensuring reliable operation. Your next step? Grab a quality multimeter and start tracking your system’s voltage behavior today.

Frequently Asked Questions About 36V Battery Voltage

What exactly does 36V mean for a battery?

A 36V nominal rating indicates the battery’s average operating voltage, but actual voltage fluctuates between 30-42V depending on charge state.

For example, a fully charged lithium-ion 36V battery actually measures 42V (4.2V per cell × 10 cells), while a “dead” battery may read 30V. The nominal value represents the midpoint of its working range during normal discharge cycles.

How do I accurately measure my 36V battery’s voltage?

Use a digital multimeter set to DC voltage with at least 0.1V precision. Connect probes directly to battery terminals (red to positive, black to negative) after the battery rests for 2+ hours post-charge/discharge.

For lithium batteries, measure individual cell voltages too – variations >0.3V indicate balancing issues. Always check voltage both at rest and under typical load conditions.

Why does my 36V battery show different voltages when charging vs discharging?

This voltage hysteresis is normal due to internal resistance. During charging, voltage appears higher (up to 42V for Li-ion) as current flows into the battery.

When discharging, voltage drops under load (may sag to 33V temporarily). The difference between charge and discharge voltages increases as batteries age – a >10% difference suggests significant wear.

How can I tell if my 36V battery is failing based on voltage readings?

Watch for these failure signs:

1) Resting voltage below 30V after full charge,

2) Rapid voltage drop under minimal load (>1V drop per 5% capacity used),

3) Inability to reach full charge voltage (42V for Li-ion), or

4) Individual cell voltage differences >0.5V.

These indicate capacity loss, internal shorts, or balancing failures requiring replacement.

Is it better to store my 36V battery fully charged or discharged?

For long-term storage, lithium batteries last longest at 40-60% charge (36-38V). Lead-acid should be stored fully charged (38.4V) with monthly top-ups.

Never store any battery below 30V. Temperature matters too – store at 15°C if possible. Example: A Li-ion stored at 42V loses 8% capacity monthly vs 2% at 38V.

How does cold weather affect my 36V battery’s voltage?

Cold causes temporary voltage depression – at 0°C, voltage drops about 0.3V per 10°C below 25°C. A 36V Li-ion showing 39V at 25°C may read 37.5V at 0°C.

This recovers when warmed. However, charging below freezing can permanently damage lithium batteries – use temperature-compensated chargers that reduce current when cold.

Can I mix different 36V battery types in the same system?

Never mix chemistries (Li-ion with lead-acid) due to different voltage characteristics. Even with same chemistry, avoid mixing old/new batteries – voltage differences cause imbalance.

If parallel connection is unavoidable, ensure voltage difference <0.5V before connecting and use blocking diodes. Series connections require identical batteries with matching cycle counts.

How often should I check my 36V battery’s voltage?

For routine maintenance:

1) Check resting voltage weekly,

2) Test under load monthly,

3) Verify full charge voltage every 3 months.

High-use systems (e.g., daily e-bikes) need more frequent checks. Smart BMS systems can automate monitoring, but manual verification is still recommended quarterly to confirm accuracy.