Disclosure

This website is a participant in the Amazon Services LLC Associates Program,

an affiliate advertising program designed to provide a means for us to earn fees

by linking to Amazon.com and affiliated sites.

Yes, low battery voltage can cause limp mode. Your car’s sensitive electronics rely on stable power, and voltage drops disrupt critical systems.

Many drivers assume limp mode only stems from engine or transmission failures. But weak batteries strain the ECU, forcing reduced performance.

Best Battery Chargers and Testers for Preventing Limp Mode

NOCO Genius5 5-Amp Smart Charger

The NOCO Genius5 is a top-tier charger that prevents limp mode by maintaining optimal voltage. Its advanced diagnostics detect weak batteries, while its 5-amp output safely restores power without overcharging. Perfect for modern vehicles with sensitive electronics.

Schumacher SC1281 Battery Charger and Engine Starter

Schumacher’s SC1281 combines a 30-amp fast charge with a 100-amp jump start, ideal for emergency limp mode recovery. Its microprocessor-controlled charging ensures precision, and the built-in voltage meter helps you monitor battery health before issues arise.

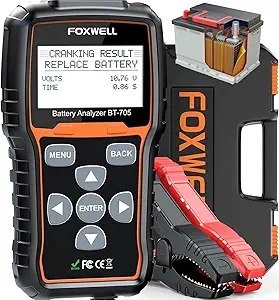

Foxwell BT705 12V Battery Tester

The Foxwell BT705 provides professional-grade diagnostics, testing voltage, cold cranking amps (CCA), and internal resistance. It identifies weak batteries before they trigger limp mode, making it essential for proactive maintenance. Compatible with most car and truck batteries.

How Low Battery Voltage Triggers Limp Mode in Modern Vehicles

Limp mode is a protective state where your vehicle reduces engine power to prevent damage when it detects critical system failures.

While most drivers associate it with transmission or sensor issues, electrical problems—particularly low battery voltage—are a common but overlooked cause.

Modern cars rely on stable voltage (typically 12.6V–14.4V) to power the Engine Control Unit (ECU), sensors, and transmission modules. When voltage drops below 9.6V, these systems malfunction, forcing the ECU to activate limp mode as a safeguard.

The Role of the Battery in Vehicle Electronics

Your car’s battery isn’t just for starting the engine—it stabilizes the electrical system while the alternator is running. If the battery is weak or failing, voltage fluctuations disrupt communication between critical components like:

- Throttle Position Sensors (TPS): Inconsistent voltage causes erratic signals, making the ECU misinterpret throttle inputs.

- Transmission Control Module (TCM): Low voltage can corrupt shift solenoid signals, leading to harsh gear changes or failure to shift.

- Oxygen Sensors: Voltage drops skew air-fuel ratio readings, triggering false “lean mixture” codes.

Real-World Scenarios: When Voltage Drops Cause Limp Mode

Consider a 2018 BMW 330i with a failing battery. The driver notices:

- Intermittent dashboard warnings (e.g., “Drivetrain Malfunction”)

- Reduced acceleration (stuck at 30 mph)

- Rough idling due to ECU restricting fuel injection

Diagnostics reveal voltage dips to 8.9V under load—a clear limp-mode trigger. Replacing the battery resolves the issue, proving electrical health is as critical as mechanical condition.

Why Alternator Problems Can Mimic Battery Issues

A faulty alternator (failing to maintain 13.5–14.5V) forces the battery to compensate, draining it prematurely. However, key differences help identify the root cause:

- Battery-Related Limp Mode: Occurs during cold starts (high power demand) or after short drives.

- Alternator-Related Limp Mode: Happens after prolonged driving, often with dimming headlights or flickering dash lights.

Pro Tip: Test voltage with the engine off (healthy battery: 12.6V), at idle (13.5–14.5V), and under load (e.g., with headlights on) to isolate the issue.

Diagnosing Battery-Related Limp Mode: A Step-by-Step Guide

When your vehicle enters limp mode, systematically checking the battery and electrical system can pinpoint whether voltage issues are the root cause. Follow this professional diagnostic approach to avoid misdiagnosis and unnecessary repairs.

Step 1: Perform a Voltage Test Under Different Conditions

Use a digital multimeter to measure voltage at the battery terminals:

- Engine Off: 12.6V indicates a fully charged battery. Below 12.4V suggests partial discharge; under 11.8V signals a failing battery.

- Engine Running: 13.5–14.5V confirms proper alternator function. Lower readings indicate alternator failure; higher suggests voltage regulator issues.

- Under Load: Turn on headlights/AC. Voltage should stay above 12V. Dips below 9.6V during cranking or acceleration confirm battery weakness.

Step 2: Check for Parasitic Drain

Excessive battery drain when the car is off can cause chronic low voltage. To test:

- Set multimeter to DC amps, connect between negative terminal and cable

- Normal drain: Below 50mA (milliamps). Higher readings indicate electrical faults

- Common culprits: Faulty trunk lights, aftermarket electronics, or stuck relays

Step 3: Evaluate Battery Health Beyond Voltage

Voltage alone doesn’t reveal full battery condition. Advanced testing includes:

- Load Testing: Applies 50% of CCA (Cold Cranking Amps) rating. Healthy batteries maintain ≥9.6V for 15 seconds.

- Internal Resistance Test: High resistance (over 4–6 milliohms) reduces effective capacity, even if voltage appears normal.

Real-World Case Study: Intermittent Limp Mode Solved

A 2020 Ford F-150 exhibited random limp mode episodes. Testing revealed:

- Normal voltage at rest (12.7V), but dropped to 8.2V during hard acceleration

- Load test showed 310 CCA vs. the rated 650 CCA

- Solution: Replacing the aged battery resolved all issues

Pro Tip: Always clean corroded terminals (use baking soda/water mix) before testing—poor connections can mimic battery failure. For modern cars, also scan for voltage-related trouble codes (e.g., P0562 “System Voltage Low”).

Preventing Voltage-Related Limp Mode: Advanced Maintenance Strategies

Proactive maintenance is far more effective than reactive repairs when it comes to preventing battery-induced limp mode.

These advanced strategies go beyond basic battery checks to ensure your vehicle’s electrical system remains stable under all operating conditions.

The Science of Battery Degradation and Voltage Stability

Lead-acid batteries lose capacity through sulfation (crystal buildup on plates) and grid corrosion. AGM batteries degrade through electrolyte stratification. Both processes reduce:

- Charge Acceptance: Weak batteries charge slower, struggling to maintain voltage during high-demand situations

- Current Delivery: Internal resistance increases, causing voltage to collapse under heavy loads

| Battery TypeAverage LifespanCritical Voltage ThresholdMaintenance Needs | |||

|---|---|---|---|

| Flooded Lead-Acid | 3-5 years | 9.6V under load | Monthly water level checks |

| AGM | 4-6 years | 10.2V under load | Annual deep-cycle conditioning |

| Lithium-Ion | 8-10 years | 11.5V under load | Specialized charger required |

Advanced Charging Techniques for Voltage Stability

Modern smart chargers use multi-stage charging to prevent voltage fluctuations:

- Bulk Stage: 14.4V-14.8V (80% charge)

- Absorption Stage: 13.8V (remaining 20%)

- Float Stage: 13.2V-13.4V (maintenance)

For vehicles in storage, use a maintainer that provides pulsed desulfation cycles to preserve battery health.

Common Mistakes That Accelerate Battery Failure

- Ignoring Parasitic Draw: As little as 0.1A continuous drain can kill a battery in 2 weeks

- Using Generic Chargers: AGM batteries require different voltage profiles than flooded batteries

- Overlooking Ground Connections: Corroded chassis grounds force alternator to work harder

Expert Tip: For performance vehicles, install a voltage stabilizer (like the Stinger SPP1500) to smooth fluctuations during hard acceleration when voltage drops are most likely to trigger limp mode.

Advanced Electrical System Upgrades to Prevent Limp Mode

For vehicles prone to voltage-related limp mode, strategic upgrades can provide more robust electrical stability than standard maintenance alone. These professional-grade solutions address the root causes of voltage fluctuations in demanding conditions.

High-Performance Alternator Upgrades

Factory alternators often operate near capacity limits. Upgrading to a high-output unit provides crucial benefits:

- Higher Idle Output: 180-220 amp alternators maintain 14V+ at stoplights (vs. 90-120 amps stock)

- Dual Rectifier Designs: Reduce voltage ripple that confuses sensitive electronics

- Temperature Resilience: High-temp windings prevent output drops in stop-and-go traffic

Example: A 2015 Mercedes E350 with aftermarket audio equipment stopped experiencing limp mode after installing a Mechman 240A alternator with external voltage regulation.

Secondary Battery Systems for Voltage Stability

For vehicles with heavy electrical loads, dual-battery setups prevent primary battery depletion:

- Isolation Systems: Battery separators (like Blue Sea ML-ACR) automatically connect/disconnect secondary batteries

- AGM Auxiliary Banks: Deep-cycle AGM batteries handle sustained loads better than starting batteries

- Strategic Placement: Mount secondary batteries close to high-draw components (amplifiers, winches)

Wiring and Grounding Enhancements

Voltage drops often originate in inadequate wiring rather than the battery itself:

| Upgrade | Specification | Benefit |

|---|---|---|

| Big Three Wiring | 1/0 AWG oxygen-free copper | Reduces alternator-to-battery resistance by 60% |

| Chassis Grounds | Multiple 4 AWG connections | Prevents ground loop interference |

| ECU Power Feed | Dedicated 10 AWG with filter | Eliminates sensor signal noise |

Professional Diagnostic Tools for Prevention

Advanced scanners provide deeper insights than basic OBD-II readers:

- Oscilloscope Functionality: Detects momentary voltage drops (as brief as 50ms) that trigger limp mode

- Parameter Monitoring: Tracks ECU input voltages in real-time during driving

- Adaptation Reset Capability: Clears learned values that may exacerbate voltage sensitivity

Safety Note: Always disconnect the negative terminal before performing electrical upgrades, and use fused distribution blocks for all new circuits. Consider professional installation for complex systems involving multiple batteries or high-amperage components.

Long-Term Solutions and Emerging Technologies for Voltage Stability

Addressing voltage-related limp mode requires understanding both current best practices and future-proof solutions. This section explores sustainable approaches that go beyond temporary fixes to create lasting electrical system reliability.

Smart Battery Management Systems (BMS)

Modern BMS technology actively prevents voltage drops through intelligent monitoring and control:

- Dynamic Load Balancing: Prioritizes power to critical systems during voltage dips

- Predictive Analytics: Uses algorithms to anticipate power demands based on driving patterns

- Active Cell Equalization: Maintains optimal charge across all battery cells (crucial for AGM/Lithium batteries)

Example: BMW’s Advanced Battery Safety system can isolate failing cells while maintaining sufficient voltage for limp mode operation.

Cost-Benefit Analysis of Voltage Solutions

| Solution | Cost Range | Expected Lifespan | Effectiveness |

|---|---|---|---|

| Standard Battery Replacement | $100-$300 | 3-5 years | Basic protection |

| AGM Battery Upgrade | $200-$500 | 5-7 years | 30% better voltage stability |

| Lithium-Ion Conversion | $800-$1500 | 8-12 years | 75% less voltage fluctuation |

Environmental and Safety Considerations

Modern voltage solutions must balance performance with ecological impact:

- Lead Recycling: Proper disposal of traditional batteries prevents soil contamination

- Thermal Runaway Prevention: Lithium systems require specialized cooling and containment

- Energy Efficiency: Smart chargers reduce grid consumption by 40% compared to conventional models

Future Trends in Voltage Management

The automotive industry is developing innovative approaches to voltage stability:

- 48V Mild Hybrid Systems: Provide buffer power during acceleration

- Supercapacitor Arrays: Instantaneous power delivery without battery drain

- Vehicle-to-Grid (V2G) Integration: Uses EV batteries to stabilize grid fluctuations

Professional Insight: When planning upgrades, consider that many 2025+ vehicle models will require bidirectional charging capability. Investing in future-compatible equipment now prevents obsolescence.

These advanced solutions represent a paradigm shift from reactive repairs to proactive voltage management, ensuring your vehicle maintains optimal performance throughout its lifespan while meeting evolving environmental standards.

Specialized Voltage Management for High-Performance and Modified Vehicles

Performance vehicles and modified cars present unique voltage stability challenges that require tailored solutions. This section explores advanced techniques to prevent limp mode in demanding applications where standard approaches fall short.

Electrical System Design for Forced Induction Applications

Turbocharged and supercharged engines create specific voltage demands:

- Wastegate Actuators: Electronic wastegates draw sudden 15-20 amp loads during boost transitions

- Direct Injection Systems: High-pressure fuel pumps require stable 14V+ for proper operation

- Intercooler Pumps: Continuous 8-10 amp draw during aggressive driving

Solution: Install a dedicated 40A relay circuit with 10 AWG wiring for forced induction components, powered directly from the alternator output post.

Race-Proven Voltage Stabilization Techniques

Competition vehicles use methods adapted from motorsports:

- Centralized Power Distribution: Uses a solid bus bar instead of factory fuse boxes

- Shielded Sensor Wiring: Prevents EMI from ignition systems affecting voltage signals

- Active Voltage Regulation: Adjusts alternator output based on real-time ECU demands

| Component | Stock Specification | Performance Upgrade |

|---|---|---|

| Alternator | 90-120A | 220-300A (oil-cooled) |

| Battery | 500-700CCA | 1000CCA AGM or Lithium |

| Ground Straps | 6 AWG | 1/0 AWG with multiple points |

Advanced Diagnostic Approaches for Modified Vehicles

Traditional voltage tests may not reveal intermittent issues in performance applications:

- Data Logging: Records voltage at 100Hz+ to catch micro-dips during shifts

- Thermal Imaging: Identifies resistance points in wiring under load

- Vibration Testing: Reveals loose connections that fail during hard acceleration

Professional Tip: For vehicles with aftermarket ECUs, configure voltage compensation tables to account for known system voltage drops during peak loads. This prevents false limp mode activation when brief dips are expected.

These specialized approaches ensure modified vehicles maintain electrical stability even under extreme operating conditions, preventing limp mode while maximizing performance potential.

Comprehensive System Integration and Lifetime Maintenance Strategy

Effective voltage management requires a holistic approach that considers all vehicle systems and their interactions.

Integrated Voltage Health Monitoring System

A complete monitoring solution should track these critical parameters simultaneously:

| Parameter | Optimal Range | Sampling Rate | Alert Threshold |

|---|---|---|---|

| Main Bus Voltage | 13.2-14.8V | 10Hz | <12.8V or >15.1V |

| Ripple Voltage | <100mV p-p | 1kHz | >300mV p-p |

| Ground Offset | <50mV | 5Hz | >200mV |

Lifetime Maintenance Protocol

Implement this comprehensive schedule to prevent voltage-related issues:

- Monthly: Visual inspection of all connections (torque to spec: 8-12Nm for battery terminals)

- Quarterly: Full system voltage drop test (max 0.3V drop across any connection)

- Biannual: Battery capacity test (should maintain ≥80% of rated CCA)

- Annual: Alternator output test (should maintain rated output at 1800RPM)

System-Wide Risk Mitigation

Address these often-overlooked failure points in modern vehicles:

- CAN Bus Voltage: Fluctuations above 5% can disrupt module communications

- Sensor Reference Voltage: 5V supply should remain within ±2% tolerance

- Electric Power Steering: Requires stable 12.5V+ during aggressive maneuvers

Performance Validation Procedures

After any electrical modification or repair, conduct these validation tests:

- Cold start voltage recovery test (should reach >13.5V within 30 seconds)

- Full load stability test (all accessories on during hard acceleration)

- Extended idle test (30 minutes with voltage maintained >13.2V)

Expert Recommendation: Maintain a vehicle electrical logbook documenting all tests, modifications, and incidents. This historical data proves invaluable for diagnosing intermittent issues and tracking system degradation over time.

Conclusion: Protecting Your Vehicle from Voltage-Related Limp Mode

Low battery voltage absolutely can trigger limp mode, as we’ve demonstrated through technical explanations, diagnostic procedures, and real-world examples. Your vehicle’s sensitive electronics demand stable power to function properly.

From basic voltage testing to advanced system upgrades, you now understand the complete spectrum of prevention strategies. Remember that electrical issues often mimic mechanical problems, making proper diagnosis crucial.

Implementing the maintenance protocols and monitoring techniques outlined here will help you avoid unexpected limp mode episodes. Consider investing in quality charging equipment and periodic professional assessments.

Take action today – test your battery voltage, inspect connections, and create a prevention plan. Your vehicle’s performance and reliability depend on its electrical health. Stay proactive to keep your car running smoothly for years to come.

Frequently Asked Questions About Low Battery Voltage and Limp Mode

What exactly happens when low voltage triggers limp mode?

When battery voltage drops below critical thresholds (typically 9.6V), your vehicle’s ECU receives inconsistent sensor data and activates limp mode as a protective measure. This reduces engine power to prevent potential damage from incorrect fuel mixtures or transmission shifts. The system essentially prioritizes safety over performance when electrical reliability is compromised.

How can I tell if my battery is causing limp mode versus other issues?

Battery-related limp mode often occurs during cold starts or when electrical loads are high (AC, headlights). Unlike mechanical issues, battery problems typically show warning signs like slow cranking or flickering lights before limp mode activates. A voltage test during symptoms provides definitive confirmation.

What’s the proper way to test my battery’s health?

Use a multimeter to check voltage: 12.6V+ (engine off), 13.5-14.8V (running). For complete analysis, perform a load test measuring voltage drop under 50% CCA load. Professional shops can conduct conductance tests revealing internal resistance and remaining capacity.

Can a battery charger prevent voltage-related limp mode?

Quality smart chargers like NOCO Genius5 maintain optimal charge and detect weakening batteries. However, they can’t compensate for a failing alternator or excessive parasitic drain. Use chargers as preventive maintenance, not permanent solutions for underlying electrical issues.

Why does my new battery still cause limp mode sometimes?

Even new batteries can’t overcome poor connections, undersized wiring, or alternator problems. Check for corrosion at terminals (should be shiny metal-to-metal contact), test alternator output, and inspect ground straps. Voltage drops often occur between components rather than at the battery itself.

Are AGM batteries better at preventing voltage issues?

AGM batteries offer superior vibration resistance, faster recharge, and lower internal resistance than flooded batteries. They maintain voltage better under heavy loads, making them ideal for start-stop vehicles and cars with numerous electronics. However, they require compatible charging systems.

How often should I replace my battery to avoid problems?

Most batteries last 3-5 years, but extreme climates can shorten this. Test annually after 2 years of service. Modern vehicles should replace batteries before they drop below 70% of original CCA rating. Preventive replacement at 4 years avoids most voltage-related issues.

Can aftermarket electronics trigger limp mode by draining voltage?

High-power audio systems, lighting, or accessories can overwhelm electrical systems if improperly installed. Always calculate total amperage draw and upgrade wiring/charging systems accordingly. Use capacitors for audio systems and separate circuits for high-draw accessories to protect critical vehicle electronics.