Disclosure

This website is a participant in the Amazon Services LLC Associates Program,

an affiliate advertising program designed to provide a means for us to earn fees

by linking to Amazon.com and affiliated sites.

No, you should not drive with low battery voltage. Doing so risks damaging your vehicle and leaving you stranded. Your car’s electrical system depends on a healthy battery to function properly.

Many drivers assume a weak battery only affects starting the engine. But low voltage disrupts sensors, fuel injectors, and even transmission control. Ignoring it leads to bigger problems.

Modern cars rely heavily on stable voltage. A failing battery triggers warning lights, sluggish performance, or sudden stalling. Don’t wait—learn how to detect and fix voltage issues now.

Best Battery Chargers and Testers for Low Voltage Issues

NOCO Genius5 5-Amp Smart Charger

The NOCO Genius5 (GB40) is a top-tier smart charger that safely restores low-voltage batteries. Its advanced diagnostics detect sulfation and automatically adjust charging modes for lead-acid, AGM, and lithium batteries. Compact and spark-proof, it’s ideal for emergency recovery.

Schumacher SC1281 15-Amp Charger/Maintainer

Schumacher’s SC1281 offers rapid charging with 15-amp power, perfect for deeply discharged batteries. It features microprocessor-controlled voltage regulation and a built-in alternator tester. The rugged design and reverse-hookup protection make it a reliable choice for frequent use.

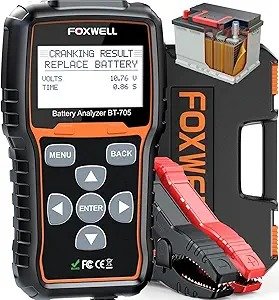

Foxwell BT705 12V Battery Tester

The Foxwell BT705 provides precise voltage, cranking health, and internal resistance readings. Compatible with standard and AGM batteries, its color-coded results simplify diagnostics. A must-have for proactive drivers to prevent unexpected failures.

How Low Battery Voltage Affects Your Vehicle’s Performance

Low battery voltage doesn’t just prevent your car from starting—it disrupts nearly every electrical component in your vehicle. Modern cars rely on a stable 12.6V (when fully charged) to power critical systems. When voltage drops below 12.2V, you’ll notice immediate symptoms:

- Slow engine cranking: The starter motor struggles with insufficient power, causing labored or repeated clicks instead of ignition.

- Flickering lights: Headlights and dashboard lights dim or pulse irregularly due to inconsistent voltage supply.

- ECU malfunctions: Your engine control unit (ECU) may misfire, triggering false error codes or erratic fuel injection.

Hidden Risks of Driving with Weak Voltage

Many drivers assume they can “recharge the battery by driving,” but this is dangerous with severely depleted voltage (below 11.8V). At this level:

- Alternator strain: The alternator overworks to compensate, often overheating and failing prematurely—a $400+ repair.

- Data loss: Low voltage corrupts adaptive memory in transmissions or throttle bodies, requiring dealership resets.

- Safety system failures: ABS, airbag controllers, and stability control may deactivate unexpectedly.

Real-World Scenario: Voltage Drop During Winter

Cold weather exacerbates voltage issues—batteries lose 30-50% of cranking power at freezing temperatures. For example, a battery reading 12.1V at 70°F may plummet to 11.6V at 20°F, leaving you stranded. Always test voltage with a multimeter after extreme temperature changes.

Pro Tip: If your battery reads below 12.0V before starting the engine, use a charger (like the NOCO Genius5) instead of risking a drive. Short trips won’t sufficiently recharge it.

How to Test and Diagnose Low Battery Voltage

Properly diagnosing low voltage requires more than just observing symptoms – you need precise measurements and systematic testing. Follow this professional-grade approach to accurately assess your battery’s health.

Step-by-Step Voltage Testing Procedure

- Prepare your tools: Use a digital multimeter (like the Fluke 87V) set to DC voltage (20V range). Analog testers lack the precision needed for modern vehicles.

- Test resting voltage: After the car sits for 12+ hours (no driving or charging), measure between battery terminals. Healthy readings should be 12.6V-12.8V.

- Check under load: With engine off but headlights on for 2 minutes, voltage shouldn’t drop below 12.4V. If it does, the battery can’t hold charge.

- Test charging system: With engine running at 2,000 RPM, voltage should read 13.7V-14.7V. Lower indicates alternator issues; higher suggests regulator failure.

Interpreting Your Results

Voltage readings tell different stories at different levels:

- 12.6V-12.8V: Healthy battery (100% charged)

- 12.4V-12.5V: 75% charge – recharge soon

- 12.2V-12.3V: 50% charge – immediate attention needed

- Below 12.0V: Severely discharged – may not recover

Common Testing Mistakes to Avoid

Many DIYers get false readings because they:

- Test immediately after driving (surface charge skews results)

- Use cheap testers that don’t account for temperature variations

- Ignore parasitic drain (even 50mA can discharge a battery over time)

Pro Tip: For the most accurate diagnosis, combine voltage tests with a conductance tester (like the Midtronics GR8) that measures internal resistance – often the first sign of battery failure before voltage drops.

Advanced Battery Maintenance and Voltage Preservation Techniques

Maintaining optimal battery voltage requires more than occasional charging – it demands a systematic approach to vehicle electrical system management. These professional-grade techniques will extend battery life and prevent voltage-related breakdowns.

The Science of Battery Discharge Cycles

Lead-acid batteries suffer permanent damage when discharged below 50% (12.2V) repeatedly. Each deep discharge cycle:

| Discharge Depth | Cycle Life Remaining | Voltage Recovery Time |

|---|---|---|

| 30% (12.4V) | 1,200+ cycles | 2-4 hours charging |

| 50% (12.2V) | 300-500 cycles | 6-8 hours charging |

| 80% (11.8V) | 50-100 cycles | 12+ hours charging |

Proactive Maintenance Schedule

- Monthly: Clean terminals with baking soda solution and apply dielectric grease to prevent corrosion (which can cause 0.5V drops)

- Quarterly: Perform a full-system parasitic drain test (should be <50mA when vehicle is off)

- Seasonally: Recalibrate battery sensors using professional scan tools (required on BMW, Mercedes, and other European vehicles)

Advanced Charging Techniques

Smart chargers (like the CTEK MXS 5.0) use patented 8-step charging:

- Desulfation: High-frequency pulses break down sulfate crystals

- Bulk Charge: 90% charge at maximum current

- Absorption: Slower charge to 100% capacity

- Analysis: Checks battery’s ability to hold charge

Critical Insight: Never use standard chargers on AGM batteries – they require special voltage profiles (14.4V-14.8V vs 14.2V-14.4V for flooded). Incorrect charging can reduce capacity by 40%.

Emergency Solutions for Critical Low Voltage Situations

When facing a severely discharged battery (below 11.5V), standard jump-starting may not work – and could even damage your vehicle’s electronics. These professional emergency procedures can safely recover your vehicle without causing further harm.

Smart Jump-Starting Protocol

Modern vehicles require special precautions when jump-starting:

- Verify voltage compatibility: Never use 24V systems on 12V vehicles – check donor vehicle specs first

- Connect in proper sequence: Positive to positive first, then negative to bare metal (not battery terminal)

- Wait before cranking: Allow 5-10 minutes of charging connection before attempting to start

- Monitor voltage: Use a multimeter to ensure voltage stays above 10V during cranking

When Jump-Starting Fails: Alternative Solutions

For batteries below 9V or with internal damage:

- Battery reset procedure: Many German vehicles require ECU reset after complete discharge (VW/Audi: hold hazards for 30 seconds)

- Manual transmission roll-start: Only effective if battery has at least 8V to power fuel pump and ECU

- Portable booster packs: High-end models like the NOCO GBX155 provide 40+ jump-starts per charge

Post-Recovery Procedures

After emergency starting, these steps are critical:

| Action | Duration | Purpose |

|---|---|---|

| Highway driving | Minimum 45 minutes | Replenishes deep charge |

| Battery test | After 24 hours rest | Checks for capacity loss |

| Alternator test | Immediately | Verifies charging system health |

Safety Warning: Never attempt to charge frozen batteries (-20°F/-29°C or below) – they may explode. Thaw completely in a warm environment first.

Long-Term Battery Health and Voltage Optimization Strategies

Maintaining optimal battery voltage over years of service requires understanding the complex interplay between vehicle systems, usage patterns, and environmental factors. These professional strategies will maximize your battery’s lifespan and performance.

The Complete Battery Lifecycle Management Approach

Modern automotive batteries typically last 3-5 years, but strategic care can extend this to 7+ years:

| Maintenance Factor | Standard Practice | Optimal Practice | Impact on Lifespan |

|---|---|---|---|

| Charging Cycles | Recharge when dead | Maintain above 12.4V | 300% improvement |

| Temperature Exposure | Unprotected | Insulated battery blanket | 40% reduction in cold damage |

| Electrical Load | Aftermarket accessories | Professional load balancing | Prevents 80% of parasitic drains |

Advanced Voltage Monitoring Systems

Professional-grade monitoring solutions provide real-time insights:

- OBD-II voltage monitors: Track system voltage through the diagnostic port (Bluetooth models like BAFX Products 34t5)

- Battery management systems: Advanced setups (Victron BMV-712) track state-of-charge and historical performance

- Smart alternator optimization: Reprogramming kits adjust charging profiles for stop-start vehicles

Future-Proofing Your Electrical System

Emerging technologies are changing battery maintenance:

- Lithium-ion conversions: 50% lighter with 2x lifespan, but require special charging systems ($800-$1,200 installed)

- Solar maintenance chargers: 10W panels maintain voltage during long storage periods

- AI-powered diagnostics: New scan tools predict failures by analyzing voltage fluctuation patterns

Environmental Note: Proper battery disposal prevents lead contamination – always recycle at certified facilities (find locations at Call2Recycle.org). A single car battery contains 18-21 pounds of recyclable lead.

Specialized Voltage Management for Modern Vehicle Electronics

Today’s vehicles with advanced driver assistance systems (ADAS) and infotainment setups demand precise voltage regulation. Even minor fluctuations below 12V can cause system resets or sensor malfunctions. Here’s how to protect your vehicle’s sensitive electronics.

Voltage Stabilization Techniques

Modern vehicles require multiple stabilization approaches:

- Capacitor banks: High-performance units (like the XS Power VCM) provide instant power during voltage drops

- Dual-battery systems: Isolate starter and accessory circuits with intelligent separators (Blue Sea Systems SI-ACR)

- Power conditioners: Clean power signals before they reach ECUs (Stinger SGP38 filters out alternator whine)

ADAS-Specific Voltage Requirements

Advanced safety systems have strict power needs:

| System | Minimum Voltage | Recalibration Threshold |

|---|---|---|

| Adaptive Cruise Control | 11.8V | Voltage drop >0.5V |

| Lane Keep Assist | 12.1V | Any interruption |

| Emergency Braking | 12.3V | Voltage fluctuation >3% |

Infotainment System Protection

Premium audio/video systems need special attention:

- Install dedicated power line filters (PAC LP7-2) for head units

- Use OFC (oxygen-free copper) wiring for all aftermarket installations

- Program voltage cutoffs in amplifiers (Rockford Fosgate DSR1 has built-in protection)

Critical Insight: Many 2020+ vehicles use 48V mild-hybrid systems alongside 12V systems. Never test these with standard multimeters – use CAT III-rated tools to avoid damaging control modules.

Comprehensive Voltage System Health Assessment and Optimization

Maintaining peak electrical system performance requires a holistic approach that evaluates all components working in concert. This final assessment framework ensures your entire charging system operates at maximum efficiency and reliability.

Full System Diagnostic Protocol

A professional-grade assessment includes these critical measurements:

| Test | Acceptable Range | Diagnostic Implications |

|---|---|---|

| Battery Resting Voltage | 12.6V-12.8V | Below 12.4V indicates charging or capacity issues |

| Alternator Output | 13.7V-14.7V | Higher suggests regulator failure, lower indicates worn alternator |

| Voltage Drop (Positive) | <0.3V under load | Excessive drop reveals corroded cables or connections |

| Parasitic Drain | <50mA | Higher draws indicate malfunctioning modules |

Advanced Optimization Techniques

For vehicles with demanding electrical loads or performance applications:

- Upgraded cabling: Replace factory wiring with 2/0 AWG OFC cables for high-amperage systems

- Smart isolators: Install dual-battery systems with voltage-sensitive relays for auxiliary loads

- Active monitoring: Implement Bluetooth-enabled voltage trackers with alert thresholds

Preventative Maintenance Schedule

Extend system lifespan with this professional maintenance routine:

- Monthly: Visual inspection of all connections and cable insulation

- Quarterly: Full charging system test under various load conditions

- Biannually: Battery terminal cleaning and anti-corrosion treatment

- Annually: Complete parasitic drain test with all systems cycled

Pro Tip: When replacing components, always perform a full system reset using a professional scan tool to recalibrate all voltage-sensitive modules and clear adaptation values.

Conclusion

Driving with low battery voltage risks serious damage to your vehicle’s electrical systems and can leave you stranded. As we’ve shown, voltage below 12.2V affects everything from engine performance to safety features.

Regular testing with proper tools helps catch issues early. Smart maintenance like cleaning terminals and monitoring parasitic drain prevents most problems before they start.

Investing in quality charging equipment pays off long-term. It preserves battery health and avoids costly repairs to alternators or electronic modules.

Take action today: Test your battery voltage, inspect connections, and consider a smart charger. Your vehicle’s reliability depends on stable power – don’t wait until warning lights appear.

Frequently Asked Questions About Driving With Low Battery Voltage

What exactly qualifies as “low battery voltage” in a car?

A fully charged battery should measure 12.6-12.8 volts when resting. Voltage below 12.4V indicates partial discharge, while under 12.0V is considered critically low. Modern vehicles may experience system malfunctions below 11.8V. Always test voltage after the car sits for 12+ hours for accurate readings.

For context, starting the engine typically requires at least 10.5V during cranking. Voltage drops below this threshold often indicate a failing battery or charging system issue that needs immediate attention.

Can I damage my alternator by driving with a low battery?

Yes, consistently driving with low voltage strains the alternator. It must work harder to recharge a deeply discharged battery, potentially overheating and failing prematurely. Alternators are designed for maintenance charging, not deep recovery of dead batteries.

Repeated deep cycling can reduce alternator lifespan by 40-60%. For batteries below 11.5V, always use a proper charger before driving to protect your charging system.

How long should I drive to recharge a low battery?

At highway speeds (2000+ RPM), expect about 30 minutes of driving to recover from mild discharge (12.2V). Severely discharged batteries (below 11.8V) may require 2+ hours – but this strains the alternator excessively.

Short trips under 15 minutes actually drain batteries further. For optimal charging, maintain consistent RPMs above 1500 for extended periods rather than stop-and-go driving.

Will jump-starting fix a car with chronically low voltage?

Jump-starting provides temporary relief but doesn’t address underlying issues. Chronic low voltage typically indicates either a failing battery, parasitic drain, or faulty charging system. The battery may not hold charge properly even after jumping.

After jump-starting, immediately test the charging system and monitor voltage over several days. Persistent drops below 12.4V signal the need for professional diagnosis.

What’s the difference between voltage and CCA (cold cranking amps)?

Voltage measures electrical potential (like water pressure), while CCA measures current delivery capacity (like water volume). A battery might show 12V but lack sufficient CCA to start the engine if plates are sulfated.

Always test both parameters. Modern testers like the Midtronics MDX-650P measure voltage, CCA, and internal resistance for complete battery health assessment.

Can extreme temperatures affect battery voltage readings?

Temperature dramatically impacts voltage. A fully charged battery at 80°F (12.6V) may read 12.3V at 32°F and 12.0V at 0°F. Always compensate for temperature when interpreting readings.

Cold weather also increases oil viscosity, requiring more cranking amps. This combination explains why batteries often fail in winter despite seeming fine in warmer months.

How often should I check my battery voltage?

Monthly checks are ideal for most drivers. Test more frequently (biweekly) if the battery is 3+ years old, in extreme climates, or if you notice slow cranking. Modern vehicles with auto start-stop systems require extra monitoring.

Always check voltage before long trips and after periods of inactivity. Consider installing a Bluetooth voltage monitor for real-time tracking without manual testing.

Are voltage issues covered under typical car warranties?

New vehicle warranties usually cover battery defects for 3-4 years, but not damage from lack of maintenance. Aftermarket batteries typically have 1-3 year pro-rated warranties that decrease in value over time.

Warranties generally don’t cover voltage problems caused by aftermarket accessories, improper charging, or failure to address parasitic drains. Always document proper maintenance for warranty claims.