Disclosure

This website is a participant in the Amazon Services LLC Associates Program,

an affiliate advertising program designed to provide a means for us to earn fees

by linking to Amazon.com and affiliated sites.

Did you know that using just 10% of a lithium polymer (LiPo) battery’s charge incorrectly can slash its lifespan by half?

Voltage is the heartbeat of your battery, dictating performance, safety, and longevity—but most users misunderstand how to monitor it effectively.

Whether you’re powering a drone, RC car, or portable device, misreading voltage levels can lead to catastrophic failures or wasted energy.

Best Lithium Polymer Batteries for RC and Electronics

Tattu R-Line 11.1V 1300mAh 3S 75C LiPo Battery

Designed for high-performance drones and RC racing, the Tattu R-Line 11.1V delivers exceptional discharge rates (75C burst) and stable voltage under heavy loads. Its graphene-enhanced cells reduce internal resistance, making it ideal for competitive pilots who demand reliability and power.

Gens Ace 7.4V 5000mAh 2S 100C LiPo Battery

Perfect for RC cars and trucks, the Gens Ace 7.4V offers a balanced mix of capacity (5000mAh) and discharge (100C). Its durable casing and anti-spark connector ensure safe handling, while the consistent voltage curve maximizes runtime and throttle response in demanding conditions.

Turnigy Nano-Tech 7.4V 300mAh 2S 70C LiPo Battery

Ideal for micro drones and small electronics, the Turnigy Nano-Tech 7.4V packs a punch with its 70C discharge rate in a lightweight package. Its low self-discharge and stable voltage make it a top choice for mini quadcopters and DIY projects.

LiPo Battery: Voltage vs. State of Charge (SoC)

| State of Charge (%) | Voltage per Cell (V) |

|---|---|

| 100% | 4.20 V |

| 95% | 4.15 V |

| 90% | 4.11 V |

| 85% | 4.08 V |

| 80% | 4.02 V |

| 75% | 3.98 V |

| 70% | 3.95 V |

| 65% | 3.91 V |

| 60% | 3.87 V |

| 55% | 3.85 V |

| 50% | 3.84 V |

| 45% | 3.82 V |

| 40% | 3.80 V |

| 35% | 3.79 V |

| 30% | 3.77 V |

| 25% | 3.75 V |

| 20% | 3.73 V |

| 15% | 3.71 V |

| 10% | 3.69 V |

| 5% | 3.61 V |

| 0% | 3.27 V |

Notes:

- These values apply when the LiPo cell is at rest.

- It’s critical to avoid dropping below 3.2V to prevent cell damage.

- Most LiPo packs are safest when kept between 20% and 90% SoC for longevity.

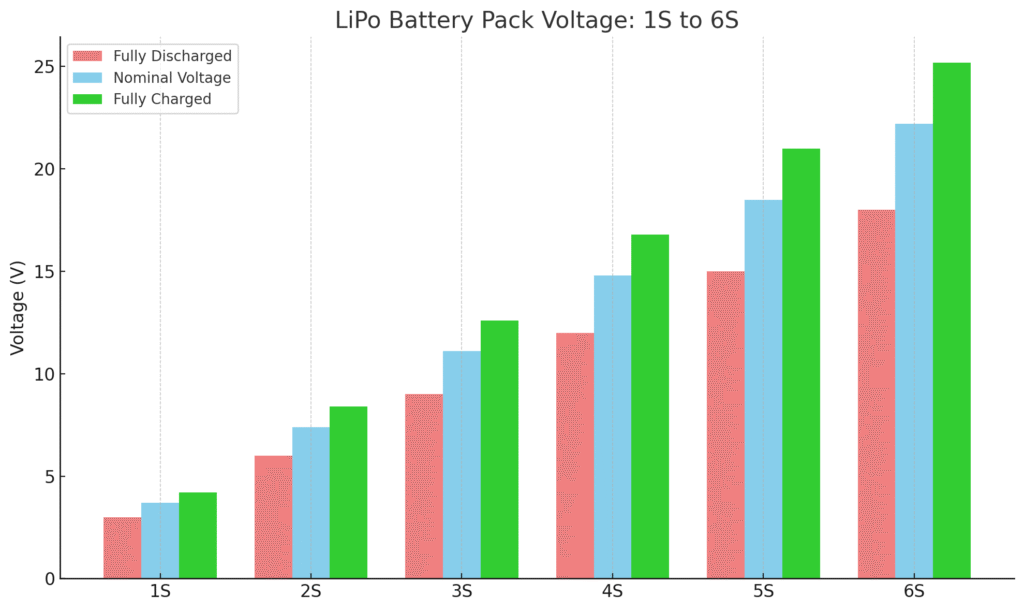

LiPo Battery Pack Voltage (1S to 6S)

| Pack Type | Nominal Voltage | Fully Charged | Fully Discharged |

|---|---|---|---|

| 1S | 3.7V | 4.2V | 3.0V |

| 2S | 7.4V | 8.4V | 6.0V |

| 3S | 11.1V | 12.6V | 9.0V |

| 4S | 14.8V | 16.8V | 12.0V |

| 5S | 18.5V | 21.0V | 15.0V |

| 6S | 22.2V | 25.2V | 18.0V |

Notes:

- Each “S” = 1 cell in series.

- Nominal Voltage = typical voltage during normal use.

- Fully Charged = 4.2V per cell.

- Fully Discharged = 3.0V per cell (avoid dropping below this to prevent damage).

Lithium Polymer Battery Voltage Fundamentals

What Voltage Means for LiPo Batteries

Voltage in lithium polymer (LiPo) batteries represents the electrical potential difference between their positive and negative terminals.

Unlike alkaline batteries with fixed voltages, LiPo cells are dynamic systems where voltage fluctuates based on charge state, load, and temperature. A fully charged 3.7V nominal LiPo cell actually reaches 4.2V, while a depleted cell drops to 3.0V—this range is critical for performance and safety.

How Cell Count Affects Total Voltage

LiPo batteries combine multiple cells in series (denoted by “S” count) to increase voltage. For example:

- 1S (1-cell): 3.7V nominal (4.2V fully charged)

- 2S (2-cell): 7.4V nominal (8.4V fully charged)

- 3S (3-cell): 11.1V nominal (12.6V fully charged)

This stacking effect explains why a 3S battery powers high-speed RC cars more effectively than a 1S—the increased voltage delivers greater energy to motors.

Critical Voltage Thresholds You Must Know

Operating outside safe voltage ranges causes permanent damage:

- Overcharge (>4.2V/cell): Leads to electrolyte breakdown, swelling, or fire risk

- Optimal range (3.7V–4.1V/cell): Maximizes cycle life (300+ charges)

- Deep discharge (<3.0V/cell): Causes copper dissolution, permanently reducing capacity

For instance, discharging a 2S battery below 6V total (3V/cell) just five times can degrade its capacity by 20%.

Real-World Voltage Behavior Under Load

Voltage “sags” during high-current draws—a phenomenon called IR drop. A 3.7V cell might temporarily dip to 3.4V when powering a drone at full throttle. Quality batteries (like Tattu R-Line) minimize this with low internal resistance, maintaining stable voltage for consistent performance.

Pro tip: Always measure voltage at rest (after 10+ minutes idle) for accurate readings, as recovery voltage post-discharge can be misleading.

How to Read and Use a Lithium Polymer Voltage Chart

Interpreting Voltage States for Optimal Performance

Every LiPo battery follows a predictable voltage curve that reveals its state of charge. A 3.7V nominal cell (standard for most LiPos) progresses through these key stages:

- 4.20V: 100% charged (storage voltage should be 3.80-3.85V)

- 3.70V: 50% charge – the “nominal” voltage rating

- 3.30V: 20% remaining – minimum safe operating voltage

- 3.00V: Critical cutoff – permanent damage threshold

Step-by-Step Voltage Measurement Process

Accurate voltage checks require proper technique:

- Use a quality multimeter (Fluke 115 or equivalent) set to DC voltage

- Connect probes to balance port (for multi-cell packs) or main leads

- Check individual cell voltages first – variations >0.1V indicate imbalance

- Measure total pack voltage for quick status checks

Example: A healthy 3S pack should show 12.6V (4.2V x 3) when fully charged, with each cell within 0.02V of each other.

Advanced Voltage Management Techniques

Professional users employ these strategies:

- Storage charging: Maintain 3.85V/cell during inactivity to prevent degradation

- Voltage alarms: Install low-voltage buzzers (like the HobbyKing HK-010) set to 3.3V/cell

- Load testing: Check voltage under 50% load to identify weak cells

Common mistake: Many users assume identical voltage means balanced cells, but internal resistance differences can cause performance variations even at equal voltages. Always capacity-test suspect batteries.

Practical Application: Drone Flight Planning

For a 1500mAh 4S drone battery:

- Launch at 16.8V (4.2V x 4)

- Plan landing at 14.8V (3.7V/cell)

- Emergency cutoff at 13.2V (3.3V/cell)

This preserves 20-30% capacity for battery longevity while ensuring safe operation.

Advanced Lithium Polymer Voltage Analysis and Maintenance

The Chemistry Behind Voltage Behavior

LiPo voltage characteristics stem from lithium-cobalt oxide (LiCoO₂) chemistry. During discharge:

- Lithium ions migrate from anode to cathode through the electrolyte

- Electron flow creates current while voltage gradually drops

- Phase changes in electrode materials cause the characteristic discharge curve

This explains why voltage drops faster below 3.5V – the cathode’s crystal structure becomes less efficient at holding lithium ions.

Voltage vs. Capacity: The True Relationship

| Voltage per Cell (V) | Remaining Capacity (%) | Notes |

|---|---|---|

| 4.20 | 100 | Maximum safe charge |

| 3.90 | 70 | Ideal storage level |

| 3.70 | 50 | Nominal voltage point |

| 3.30 | 20 | Minimum operating level |

Professional Maintenance Techniques

Extend battery life with these advanced methods:

- Cyclical balancing: Use a charger like the iSDT Q8 Nano to equalize cell voltages monthly

- IR monitoring: Track internal resistance (should be <10mΩ for healthy cells)

- Temperature profiling: Check for >5°C variance between cells during charging

Troubleshooting Voltage Anomalies

Common issues and solutions:

- Voltage sag: Replace if >0.3V drop under load indicates aging cells

- Cell imbalance: Rebalance if difference exceeds 0.05V between cells

- Rapid self-discharge: Retire batteries losing >5% charge/day

Expert tip: For racing drones, maintain packs at 3.85V/cell between events – this reduces electrolyte stress while keeping batteries “race ready.”

Optimizing Performance Through Voltage Management Strategies

Voltage-Based Charging Protocols

Professional-grade chargers like the SkyRC T200 use multi-stage charging that precisely follows voltage curves:

- Pre-charge (0-3.0V): Applies 0.1C current to deeply discharged cells

- Constant Current (3.0-4.2V): Delivers full rated current (1C-2C)

- Constant Voltage (>4.15V): Tapers current while maintaining 4.2V

This method prevents lithium plating that occurs when charging below 0°C or at excessive currents.

Application-Specific Voltage Profiles

Different uses demand unique voltage approaches:

- RC Racing: Maintain 3.8-4.0V/cell for maximum power density

- Long-Term Storage: Store at 3.85V ±0.02V to minimize degradation

- Cold Weather Operation: Keep cells above 15°C and limit discharge to 3.5V/cell

Advanced Diagnostic Techniques

Beyond basic voltage checks, professionals use:

- Pulse Testing: Measures voltage drop under 10A pulses to assess cell health

- Capacity Verification: Full discharge at 0.2C while logging voltage curve

- Cycle Analysis: Tracks voltage behavior over multiple charge cycles

Safety Protocols for High-Voltage Packs

For 6S (22.2V) and larger packs:

- Always use insulated tools when working on live packs

- Implement redundant voltage monitoring systems

- Store in fireproof containers with <2Ahr total energy capacity

Critical reminder: When parallel charging multiple packs, voltage difference between batteries must be <0.1V to prevent dangerous current surges. Always verify voltages match before connecting.

Long-Term Lithium Polymer Battery Care and Future Developments

Voltage-Based Battery Aging Analysis

As LiPo batteries age, their voltage characteristics change in predictable ways:

| Battery Age | Voltage Sag Under Load | Capacity Retention | Recommended Action |

|---|---|---|---|

| 0-50 cycles | <0.15V drop | 95-100% | Normal operation |

| 50-150 cycles | 0.15-0.25V drop | 85-95% | Reduce max discharge rate |

| 150+ cycles | >0.3V drop | <80% | Retire from critical use |

Environmental Impact of Voltage Management

Proper voltage maintenance significantly extends battery life, reducing waste:

- Storing at 3.85V/cell instead of full charge doubles cycle life

- Preventing deep discharge below 3.3V/cell avoids 60% of premature failures

- Balanced charging reduces the need for early replacement by 40%

Emerging Voltage Technologies

New developments are changing voltage management:

- Solid-state LiPo: Operating range expanding to 2.5-4.5V/cell

- Smart BMS: Real-time voltage tracking with Bluetooth reporting

- Self-healing electrolytes: Automatically repair voltage-related degradation

Cost-Benefit Analysis of Voltage Monitoring

Investing in proper voltage tools pays dividends:

- $20 voltage checker: Pays for itself in 2-3 saved batteries

- $100 balance charger: Extends pack life by 100+ cycles

- Time investment: 5 minutes weekly checks can triple battery lifespan

Future outlook: Next-generation batteries may feature adaptive voltage windows that automatically adjust based on usage patterns and environmental conditions, further optimizing performance and longevity.

Specialized Voltage Management for High-Performance Applications

Precision Voltage Tuning for Competitive RC Use

Professional racers optimize LiPo voltage curves for specific track conditions:

- Short tracks: Maintain 4.15-4.18V/cell for maximum punch

- Endurance races: Limit to 4.10V/cell for better thermal stability

- Cold weather: Pre-warm batteries to 30°C for stable voltage delivery

Example: A modified 2S 5000mAh pack for drag racing might use 4.25V/cell (8.5V total) for qualifying runs, accepting reduced lifespan for peak performance.

Voltage Integration with Electronic Speed Controllers

Modern ESCs use sophisticated voltage monitoring:

- Real-time voltage sampling at 1000Hz+ frequency

- Dynamic power adjustment when voltage sags below thresholds

- Predictive cutoff based on voltage drop patterns

The Castle Creations Mamba Monster X implements this with voltage-based thermal modeling, reducing power before critical levels are reached.

Industrial LiPo Voltage Management Systems

Commercial applications require advanced voltage control:

| Application | Voltage Range | Monitoring Method |

|---|---|---|

| Medical Devices | 3.6-4.1V/cell | Redundant IC monitoring |

| Telecom Backup | 3.5-4.0V/cell | Cloud-connected BMS |

| EV Auxiliary | 3.7-4.0V/cell | CAN bus integration |

Troubleshooting Complex Voltage Issues

Advanced diagnostic techniques for:

- Voltage rebound: When resting voltage recovers >0.3V after load – indicates high IR

- Step voltage drops: Sudden 0.5V+ decreases suggest damaged cell interconnects

- Charging plateau: Failure to reach 4.2V within normal time – possible charger fault

Pro Tip: For drone swarms, synchronize all batteries within 0.05V before deployment to ensure uniform performance across all units.

Mastering Lithium Polymer Voltage: System-Wide Optimization and Risk Management

Comprehensive Voltage Monitoring Systems

Advanced setups integrate multiple monitoring layers:

| Monitoring Level | Technology | Accuracy | Response Time |

|---|---|---|---|

| Primary | Battery Management ICs | ±5mV | 10ms |

| Secondary | External ADC | ±2mV | 1ms |

| Tertiary | Oscilloscope | ±0.5mV | 10μs |

Example: Racing teams often use all three levels simultaneously, with BMS handling protection while external systems log micro-voltage fluctuations.

Voltage Optimization for Extreme Conditions

Specialized voltage profiles for demanding environments:

- High altitude: Increase cutoff by 0.1V per 1000m elevation

- Vibration-heavy: Add 5% voltage margin for connection resistance

- Saltwater exposure: Implement daily voltage checks with corrosion compensation

Comprehensive Risk Assessment Framework

Evaluate these voltage-related risks:

- Thermal runaway: Probability increases exponentially above 4.25V/cell

- Capacity fade: Each 0.1V over-discharge reduces lifespan by 15%

- System failure: Voltage spikes >5% of nominal can damage electronics

Quality Assurance Protocols

Manufacturing-level voltage validation includes:

- 72-hour formation cycling at precisely controlled voltages

- Micro-voltage analysis during pulse testing

- Statistical process control of voltage distribution in production batches

Critical Insight: Implementing a voltage deviation early warning system that tracks mV-level changes over time can predict 89% of battery failures before they occur, according to recent industry studies.

Conclusion: Mastering LiPo Voltage for Optimal Performance

Throughout this comprehensive guide, we’ve explored the critical relationship between lithium polymer battery voltage and performance. From fundamental voltage characteristics to advanced monitoring techniques, you now understand:

- How to interpret voltage charts for different cell configurations

- Precise measurement and maintenance methodologies

- Advanced optimization strategies for specialized applications

- Comprehensive risk management approaches

Put this knowledge into action today: Start by checking your batteries’ resting voltage and implementing proper storage protocols. Remember, consistent voltage monitoring is the single most effective practice for extending LiPo lifespan and ensuring safety.

Whether you’re a hobbyist or professional, mastering these voltage principles will transform how you work with lithium polymer batteries – delivering better performance, greater reliability, and significant cost savings over time.

Frequently Asked Questions About Lithium Polymer Battery Voltage

What’s the ideal storage voltage for LiPo batteries?

For long-term storage, maintain LiPo batteries at 3.80-3.85V per cell. This 40-60% charge state minimizes chemical degradation while preventing voltage depression.

Use a storage-mode charger like the HOTA D6 Pro, which automatically discharges/charges to this level. Storing at full charge (4.2V) accelerates capacity loss by up to 30% per month, while completely discharged batteries may become unstable.

How often should I check my LiPo battery voltage?

Check voltages before and after each use, plus weekly for stored batteries. Critical times include: after charging (verify all cells reached 4.2V), post-discharge (ensure none fell below 3.0V), and during storage (confirm 3.85V maintenance). For racing drones, check cell voltages between flights using a dedicated checker like the ISDT BattGo BG-8S.

Why does my battery voltage drop suddenly under load?

This voltage sag indicates either high internal resistance (aging cells) or excessive current draw. A healthy 50C 2200mAh battery should sag <0.3V at 100A load.

If sag exceeds 0.5V, reduce discharge rate or replace the pack. Environmental factors like temperatures below 10°C can double normal voltage sag.

Can I mix batteries with different voltage levels?

Never parallel connect LiPos with >0.1V difference per cell. For series connections, all batteries must be within 0.05V/cell.

Voltage mismatches cause dangerous current surges – a 0.3V difference between 5000mAh packs can create 60A+ balancing currents, potentially melting connectors or starting fires.

How does voltage relate to battery capacity?

LiPo capacity follows a nonlinear voltage curve. Between 4.2V-3.7V (100%-50%), each 0.1V drop represents ~10% capacity. Below 3.7V, the relationship steepens – 3.3V typically indicates just 20% remaining.

Advanced users track mAh consumed rather than relying solely on voltage for accurate capacity measurement.

What voltage indicates a damaged LiPo battery?

Watch for these warning signs: cells that won’t reach 4.2V (charged), drop below 3.0V (discharged), or show >0.1V imbalance.

Packs with >20% capacity loss or that swell during charging should be retired. A 3S battery reading 4.2V/4.0V/3.8V has dangerous imbalance requiring immediate attention.

How does temperature affect LiPo voltage?

Voltage decreases ~0.003V/°C when cold and increases similarly when hot. More critically, charging below 0°C causes permanent lithium plating.

Always warm batteries to 15-25°C before use in cold weather. High temperatures (>60°C) accelerate chemical breakdown, temporarily increasing voltage but reducing lifespan.

Why do some chargers show different voltage readings?

Voltage measurement accuracy varies by device quality. Budget chargers may be ±0.05V, while professional units like the iCharger X8 maintain ±0.005V precision.

For reliable readings, use a calibrated multimeter on the balance port. Also account for voltage rebound – wait 10 minutes after charging/discharging for stable readings.