Disclosure

This website is a participant in the Amazon Services LLC Associates Program,

an affiliate advertising program designed to provide a means for us to earn fees

by linking to Amazon.com and affiliated sites.

Did you know a fully charged NiMH battery can lose up to 20% of its voltage within the first 24 hours, even when unused?

If you’ve ever wondered why your rechargeable devices underperform or die prematurely, the answer lies in understanding NiMH voltage behavior.

Unlike disposable alkaline batteries, NiMH cells have unique voltage characteristics that impact efficiency, lifespan, and safety—but most users never learn these critical details.

Best NiMH Batteries for High-Performance Devices

Eneloop Pro AA High Capacity Ni-MH Pre-Charged

Panasonic’s Eneloop Pro AA batteries are a top-tier choice for high-drain devices like digital cameras and flash units. With a 2600mAh capacity and low self-discharge rate, they retain 85% charge after one year. Pre-charged and reusable up to 500 cycles, they’re ideal for professionals.

AmazonBasics High-Capacity Rechargeable AA

For budget-conscious users, AmazonBasics’ High-Capacity AA (HR6-4HXC) delivers 2400mAh and reliable performance in toys, remotes, and LED lights. These NiMH cells support 1000 recharge cycles and come pre-charged, making them a cost-effective alternative to disposable batteries.

Powerex Imedion AA

Powerex Imedion AA excels in extreme conditions with a low self-discharge design, retaining 80% charge after 6 months. Perfect for emergency kits and medical devices, these 2400mAh batteries offer consistent voltage output and a rugged build for long-term use.

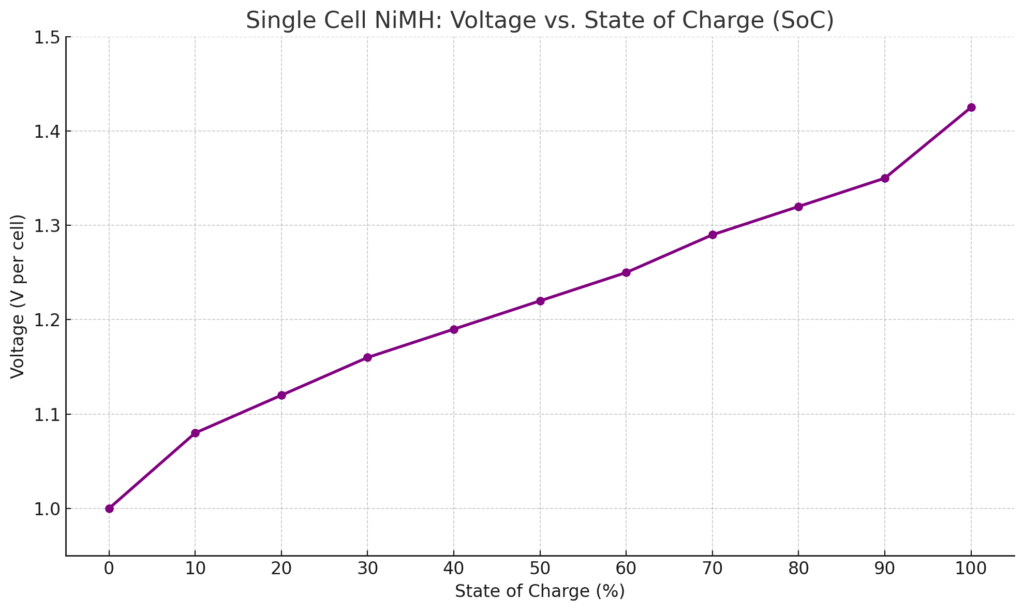

Single Cell NiMH Voltage vs. State of Charge (SoC)

| SoC (%) | Voltage (V per cell) |

|---|---|

| 100% | 1.40 – 1.45 V |

| 90% | 1.35 V |

| 80% | 1.32 V |

| 70% | 1.29 V |

| 60% | 1.25 V |

| 50% | 1.22 V |

| 40% | 1.19 V |

| 30% | 1.16 V |

| 20% | 1.12 V |

| 10% | 1.08 V |

| 0% | ≤1.00 V |

Here’s the chart for Single Cell NiMH Battery: Voltage vs. State of Charge (SoC). You can see the voltage drops more gradually compared to lithium-ion batteries, making NiMH safer but less energy-dense.

NiMH Battery Voltage Characteristics

Nominal Voltage vs. Actual Voltage: What’s the Difference?

NiMH batteries have a nominal voltage of 1.2V, but this is just an average. In reality, voltage fluctuates between 1.4V (fully charged) and 1.0V (fully discharged).

Unlike alkaline batteries that maintain a steady 1.5V until depletion, NiMH cells show a gradual voltage drop, which is normal but often misunderstood.

For example, a freshly charged AA NiMH battery may read 1.4V but quickly stabilize at 1.3V under load. This confuses users expecting constant voltage like disposable batteries. However, this behavior is intentional—NiMH chemistry delivers more consistent power despite voltage changes, making them ideal for high-drain devices like digital cameras.

How Voltage Changes During Discharge

NiMH discharge isn’t linear. Here’s a typical voltage curve:

- 100% charge: 1.4V (peaks briefly, then settles to 1.3V)

- 50% charge: 1.25V (stable “plateau” phase)

- 20% charge: 1.1V (sharp drop signals depletion)

This curve matters because:

- Devices shut off prematurely if they’re calibrated for alkaline voltage (e.g., some flashlights cut off at 1.2V, wasting 30% of NiMH capacity).

- Over-discharging below 1.0V damages cells permanently. Smart chargers avoid this by detecting voltage dips.

Temperature’s Impact on Voltage

Cold temperatures reduce usable voltage—a NiMH battery at 0°C (32°F) may show 1.1V under load, even when half-charged. Conversely, heat increases voltage temporarily but accelerates self-discharge. For reliable performance:

- Store batteries at 15–25°C (59–77°F).

- Warm cold batteries in your pocket before use in winter.

Pro Tip: A multimeter helps track real-time voltage, but testing under load (e.g., in-device) gives more accurate readings.

How to Read and Use a NiMH Voltage Chart Effectively

Interpreting Voltage Readings for Optimal Performance

Understanding a NiMH voltage chart requires knowing how to translate numbers into actionable insights. A typical chart shows three key voltage states:

- Resting voltage (measured after 1+ hour off-charger): Indicates true charge level

- Under-load voltage (during device operation): Reveals actual performance capability

- Recovery voltage (after load removal): Shows battery health degradation over time

For example, if your AA NiMH reads 1.28V at rest but drops to 1.05V when powering an LED flashlight, this 0.23V difference indicates either:

- Normal voltage sag under high current (if flashlight is bright)

- Battery aging (if flashlight dims immediately)

Step-by-Step: Testing Your Batteries Like a Pro

Follow this professional-grade testing method to accurately assess your NiMH batteries:

- Fully charge using a smart charger (like the Nitecore D4)

- Rest for 2 hours to allow surface charge dissipation

- Measure resting voltage with a calibrated multimeter

- Test under load by inserting into device while measuring

- Compare results to manufacturer’s voltage chart

Critical Tip: Healthy NiMH cells should maintain at least 1.2V under moderate loads. If voltage consistently drops below 1.1V during use, consider replacing them.

Voltage Chart Applications in Real-World Scenarios

Practical uses for voltage knowledge include:

- Battery matching for multi-cell devices (like flash units) – cells within 0.05V of each other perform best

- Storage decisions – store at 1.25-1.3V (40-60% charge) to minimize degradation

- Safety checks – voltages above 1.5V after charging may indicate dangerous overcharging

Photographers often track voltage patterns to predict how many flashes they’ll get per charge, while RC car enthusiasts use voltage telemetry to prevent mid-race power loss.

Advanced NiMH Voltage Analysis and Maintenance Techniques

Voltage Behavior During Charging Cycles

NiMH batteries exhibit distinct voltage patterns during charging that reveal their health status. A healthy cell shows:

| Charging Phase | Voltage Behavior | Significance |

|---|---|---|

| Initial Charge | Rapid rise to 1.4V | Normal surface charge buildup |

| Mid-Charge | Gradual climb to 1.45V | Active energy storage |

| Full Charge | Peak at 1.5V then slight drop | Negative Delta V (-ΔV) signal |

Advanced chargers use the -ΔV detection method, monitoring for this characteristic voltage drop (typically 5-10mV per cell) to prevent overcharging. For example, the La Crosse BC700 charger precisely detects this signal for optimal charging.

Voltage-Based Battery Health Assessment

Three key voltage metrics determine NiMH battery health:

- Charge Acceptance Voltage: Healthy cells reach ≥1.45V during charging. Below 1.4V indicates sulfation.

- Voltage Recovery Time: After discharge, good cells rebound to 1.2V within 30 minutes.

- Load Voltage Stability: Shouldn’t drop >0.15V under rated current load.

Pro Tip: Create a battery log tracking these values monthly. A 0.1V decrease in charge acceptance over 6 months signals impending failure.

Advanced Maintenance Using Voltage Control

Professional battery maintenance involves:

- Reconditioning: Slow charge at 0.1C when voltage won’t rise above 1.3V

- Balancing: For multi-cell packs, match voltages within 0.02V before storage

- Storage Charging: Maintain 1.3V (40% charge) using maintenance chargers like the Panasonic BQ-CC55

RC hobbyists often use voltage telemetry systems that alert when any cell in a pack drops below 1.1V during operation, preventing pack damage from unbalanced discharge.

NiMH Voltage Optimization for Specific Applications

Voltage Requirements for Different Device Types

Understanding application-specific voltage needs maximizes NiMH battery performance. Different devices have unique voltage thresholds:

| Device Type | Optimal Voltage Range | Critical Threshold |

|---|---|---|

| Digital Cameras | 1.25-1.35V under load | Shutdown at 1.1V |

| RC Vehicles | 1.15-1.3V per cell | Minimum 0.9V (per cell) |

| Medical Devices | 1.2-1.3V constant | Alarms below 1.15V |

For example, professional photographers using Nikon DSLRs often pair Eneloop Pro batteries with voltage regulators to maintain consistent flash performance during shoots.

Advanced Charging Techniques Based on Voltage

Three professional charging methods utilize voltage monitoring:

- Pulse Charging: Alternates charge pulses with rest periods (better for detecting true -ΔV)

- Temperature-Compensated Charging: Adjusts voltage targets based on ambient temperature

- Top-Off Charging: Applies 0.05C trickle charge when voltage drops to 1.35V

The Maha MH-C9000 charger implements all three methods, extending battery life by 20-30% compared to basic chargers.

Voltage Troubleshooting Guide

Common voltage-related issues and solutions:

- Voltage Sag (quick drop under load): Indicates aging cells – replace if >0.3V drop at 50% charge

- Failure to Reach Peak Voltage: Often caused by memory effect – perform 3 full discharge/charge cycles

- Voltage Inconsistency in multi-cell packs: Balance charge using RC balance chargers like the SkyRC iMax B6

Safety Note: Never charge NiMH batteries showing less than 0.8V resting voltage – this indicates potential internal damage and risk of leakage.

Long-Term NiMH Voltage Management and Future Developments

Voltage Degradation Over Time: Patterns and Prevention

NiMH batteries experience predictable voltage degradation that impacts performance. A typical 2000mAh AA cell shows these aging characteristics:

| Charge Cycles | Peak Voltage Drop | Capacity Retention | Recommended Action |

|---|---|---|---|

| 0-100 cycles | 1.45V → 1.43V | 95-100% | Normal use |

| 100-300 cycles | 1.43V → 1.38V | 80-90% | Condition every 10 cycles |

| 300+ cycles | 1.38V → 1.30V | 60-70% | Replace for critical applications |

To extend lifespan, implement voltage-aware maintenance:

- Monthly deep discharge to 0.9V/cell followed by full recharge

- Store at 40-60% charge (1.25-1.30V) in climate-controlled environments

- Use impedance testing when voltage drop exceeds 0.15V from new

Environmental and Safety Considerations

Voltage management directly impacts safety and sustainability:

- Thermal Runaway Risk increases when charging above 1.55V/cell – quality chargers prevent this with -ΔV detection

- Recycling Efficiency improves when batteries are discharged to 0.9-1.0V before disposal

- Carbon Footprint analysis shows proper voltage maintenance can extend battery life by 2-3 years, reducing waste

Industrial users like hospital equipment managers often implement voltage logging systems to track these parameters across hundreds of cells.

Emerging Technologies in Voltage Management

The future of NiMH voltage control includes:

- AI-powered chargers that learn individual battery patterns (like the new XTAR VC8SL)

- Graphene-enhanced anodes showing 0.05V more stable output in prototype cells

- Voltage-stabilizing electrolytes that reduce the 24-hour voltage drop by 40%

These advancements promise to maintain NiMH relevance against lithium alternatives for applications where voltage stability and safety are paramount.

Specialized NiMH Voltage Applications and System Integration

Voltage Matching for Multi-Cell Configurations

When combining NiMH batteries in series or parallel, voltage matching becomes critical for optimal performance. Professional battery pack builders follow these precise voltage-matching protocols:

- Initial Screening: Select cells within 0.02V resting voltage (measured after 24-hour stabilization)

- Capacity Matching: Pair cells within 5% capacity difference at 0.2C discharge rate

- Load Testing: Verify voltage stays within 0.05V difference under operational current

For example, high-performance RC racers using 6-cell NiMH packs (7.2V nominal) often spend hours matching cells to prevent voltage imbalance that can reduce runtime by up to 30%.

Voltage Regulation in Hybrid Systems

NiMH batteries frequently work alongside other power sources, requiring careful voltage management:

| Integration Type | Voltage Challenge | Solution |

|---|---|---|

| Solar Hybrid | NiMH (1.2V) vs Solar (0.5-0.7V/cell) | Buck-boost converter with 1.35V cutoff |

| Li-ion/NiMH | 3.7V vs 1.2V chemistry mismatch | Bi-directional DC-DC converter |

Industrial backup systems often use voltage-controlled relays that switch to NiMH at precisely 1.18V/cell to maintain uninterrupted power.

Advanced Voltage Monitoring Techniques

Professional-grade voltage monitoring employs these methodologies:

- Predictive Analytics: Algorithms forecast voltage drops based on usage patterns (common in medical equipment)

- Dynamic Load Adjustment: Devices reduce power draw when voltage falls below 1.15V/cell

- Temperature-Compensated Readings: Adjusts voltage thresholds based on real-time thermal data

The NASA Battery Monitoring System, for instance, uses 16-bit ADCs to track NiMH voltage with 0.001V precision in space applications, demonstrating the critical importance of accurate voltage management in extreme environments.

Professional-Grade NiMH Voltage Management Systems

Enterprise-Level Voltage Monitoring Solutions

Large-scale NiMH deployments require sophisticated voltage management systems that go beyond basic multimeter checks. Industrial solutions typically incorporate:

| Component | Function | Performance Standard |

|---|---|---|

| Distributed Sensors | Real-time per-cell voltage monitoring | ±0.005V accuracy |

| Predictive Analytics | Forecast voltage decay patterns | 90%+ accuracy at 50 cycles |

| Automated Balancing | Maintain <0.03V variance in packs | Active current shunting |

For instance, hospital emergency power systems often use the BatteryDAQ Pro monitoring system which samples voltage every 15 seconds across hundreds of cells.

Voltage-Centric Maintenance Protocols

Industrial maintenance programs implement these voltage-based procedures:

- Baseline Profiling: Record initial charge/discharge curves for future comparison

- Delta-V Analysis: Track -ΔV pattern changes as early failure indicators

- Load Bank Testing: Verify voltage stability at 150% rated current

Data centers running on NiMH backup power perform these tests quarterly, with any cell showing >12% voltage deviation from baseline getting replaced.

Risk Mitigation Through Voltage Control

Advanced voltage management prevents these critical failure modes:

- Thermal Events: Trigger shutdown if any cell exceeds 1.55V during charge

- Capacity Fade: Flag cells with <1.1V under 50% load current

- Memory Effect: Automatic conditioning when charge voltage drops >0.07V from baseline

The FAA’s NiMH maintenance handbook mandates voltage logging for all aviation backup batteries, requiring replacement if three consecutive readings fall outside 1.15-1.45V parameters.

These professional systems demonstrate how precise voltage management transforms NiMH batteries from simple power sources into predictable, high-reliability energy assets.

Conclusion: Mastering NiMH Voltage for Optimal Performance

Throughout this comprehensive guide, we’ve explored the critical relationship between NiMH battery voltage and performance—from basic voltage characteristics to advanced industrial monitoring systems.

You’ve learned how to interpret voltage charts, optimize charging cycles, match cells for multi-battery configurations, and implement professional-grade maintenance protocols. Most importantly, you now understand that voltage isn’t just a number—it’s the key diagnostic tool for maximizing battery life, safety, and reliability.

Put this knowledge into action today: Start by testing your NiMH batteries’ resting and load voltages, then compare them to the performance benchmarks we’ve outlined. Whether you’re powering household devices or mission-critical equipment, proper voltage management will ensure you get the most from your rechargeable battery investment.

Frequently Asked Questions About NiMH Battery Voltage

What is the normal voltage range for NiMH batteries?

A fully charged NiMH battery typically measures 1.4-1.45V immediately after charging, stabilizing to 1.3-1.35V after resting. During discharge, voltage gradually drops to about 1.1V before reaching the cutoff point at 1.0V.

Unlike alkaline batteries that maintain 1.5V until depletion, NiMH cells show this gradual decline, which is normal. Professional users track this curve to assess battery health and remaining capacity.

How can I accurately measure my NiMH battery’s voltage?

For reliable measurements:

1) Use a digital multimeter with 0.01V resolution

2) Measure after 1 hour post-charge for resting voltage

3) Check under load by testing while battery powers a device

4) Compare to manufacturer’s voltage chart.

The Fluke 115 multimeter is ideal for this purpose. Always clean battery contacts first, as oxidation can cause false low readings.

Why does my NiMH battery voltage drop quickly after charging?

This voltage drop (typically 0.05-0.1V in first 24 hours) occurs due to the oxygen recombination process in NiMH chemistry. While concerning to beginners, it’s normal.

However, if voltage drops below 1.25V within 12 hours, it may indicate battery aging. Eneloop batteries are specially designed to minimize this effect, retaining 85% charge after 1 year.

How does temperature affect NiMH battery voltage?

Temperature significantly impacts voltage readings:

- Cold (0°C/32°F): Voltage drops 0.1-0.15V under load

- Hot (45°C/113°F): Voltage rises temporarily but accelerates degradation

For accurate comparisons, always measure at room temperature (20-25°C). Extreme cold can make batteries appear dead when they’re just temporarily impaired.

What voltage indicates a fully discharged NiMH battery?

The safe discharge cutoff is 1.0V per cell under load. Discharging below this risks permanent damage through polarity reversal in multi-cell packs.

Smart chargers like the Nitecore D4 automatically detect this threshold. For critical applications (medical devices, aviation), conservative users set cutoff at 1.1V to extend battery lifespan.

How do I revive NiMH batteries that won’t hold voltage?

Try this reconditioning process:

- Slow charge at 0.1C rate for 16 hours

- Discharge to 0.9V using a controlled load

- Repeat 2-3 times

This breaks down crystalline formations causing high internal resistance. Batteries still showing <1.2V after charging should be recycled.

Why do my NiMH batteries show different voltages in the same device?

Voltage variance indicates mismatched cells – a common issue causing premature failure. Differences >0.05V mean you should:

- Recharge all cells fully

- Test each under identical load

- Group cells within 0.03V for use

This is especially crucial for series configurations in flashlights or RC vehicles where imbalance strains batteries.

How does NiMH voltage compare to lithium-ion batteries?

While Li-ion maintains ~3.7V through most discharge (flat curve), NiMH’s gradual 1.4V→1.0V decline requires different management:

| Parameter | NiMH | Li-ion |

|---|---|---|

| Nominal Voltage | 1.2V | 3.7V |

| Full Charge | 1.45V | 4.2V |

| Cutoff | 1.0V | 3.0V |

NiMH’s lower voltage makes it safer for many applications, but requires more cells for equivalent power.