Disclosure

This website is a participant in the Amazon Services LLC Associates Program,

an affiliate advertising program designed to provide a means for us to earn fees

by linking to Amazon.com and affiliated sites.

Most people assume all chargers are interchangeable, but the truth lies in voltage—the silent killer of battery health.

Your phone’s performance, charging speed, and even safety depend on maintaining the correct voltage range. But what exactly is “normal,” and how do you avoid dangerous spikes or drops?

Best Multimeters for Testing Phone Battery Voltage

Fluke 117 Electrician’s Multimeter

The Fluke 117 is a top-tier multimeter with True RMS voltage measurement, ensuring precise readings for lithium-ion phone batteries (3.7V–4.2V). Its compact design, auto-ranging, and low-input impedance prevent ghost voltage errors—critical for diagnosing charging issues or battery degradation.

Klein Tools MM325 Multimeter

Ideal for beginners, the Klein Tools MM325 offers a dedicated 20V DC range, perfect for testing phone battery voltage without overloading. Its rugged build, backlit display, and continuity buzzer make it a reliable, affordable choice for troubleshooting charging ports or power banks.

ANENG AN8008 True RMS Digital Multimeter

For budget-conscious users, the ANENG AN8008 delivers lab-grade accuracy (±0.5%) with a fast refresh rate, capturing voltage fluctuations in real time. Its slim profile and micro-USB charging compatibility mirror the portability of the devices it tests—great for on-the-go diagnostics.

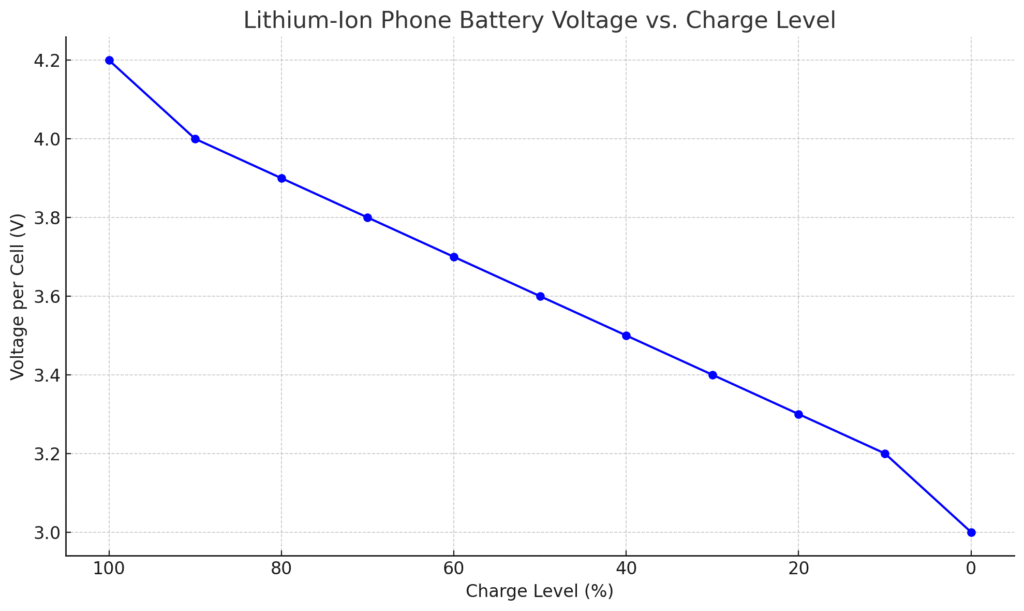

Lithium-Ion Phone Battery Voltage Chart

| Charge Level | Voltage per Cell | Battery Status |

|---|---|---|

| 100% | 4.2V | Fully charged |

| 90% | 4.0V | High charge |

| 80% | 3.9V | Moderate to high |

| 70% | 3.8V | Moderate |

| 60% | 3.7V | Typical operating voltage |

| 50% | 3.6V | Half charged |

| 40% | 3.5V | Low charge |

| 30% | 3.4V | Very low |

| 20% | 3.3V | Near depletion |

| 10% | 3.2V | Critical level |

| 0% | 3.0V or lower | Recharge immediately |

The above is a graph showing the relationship between lithium-ion phone battery voltage and charge level. As you can see, the voltage gradually drops as the charge level decreases, with 4.2V representing a fully charged state and 3.0V indicating the battery is fully discharged

Phone Battery Voltage: Key Ranges and Their Impact

Standard Voltage Ranges for Lithium-Ion Batteries

Most smartphones use lithium-ion (Li-ion) or lithium-polymer (LiPo) batteries, which operate within specific voltage ranges.

A fully charged battery typically measures 4.2V, while a completely discharged one drops to around 3.0V. The nominal voltage—the average operating level—is usually 3.7V. Deviations outside these ranges can indicate battery damage, charging circuit failures, or safety risks like swelling or overheating.

Why Voltage Matters for Battery Health

Voltage directly impacts your phone’s performance and longevity. For example:

- Overcharging (above 4.2V): Causes stress on the battery, accelerating wear and increasing the risk of leaks or explosions.

- Deep discharge (below 3.0V): Triggers a protection circuit to shut down the device, but repeated cycles can permanently reduce capacity.

- Optimal range (3.6V–4.1V): Balances energy output and lifespan, which is why manufacturers limit fast charging to 80% in some modes.

Real-World Voltage Scenarios and Troubleshooting

Consider these common issues tied to voltage:

- Rapid battery drain: If your phone dies at 20%, the battery might be “lying” due to voltage calibration errors. Recalibrating by fully discharging and charging can help.

- Slow charging: A faulty charger or cable may deliver inconsistent voltage, trickling power at 3V instead of the required 5V/9V for fast charging.

- Swollen battery: Often caused by overvoltage from a defective charger, which breaks down internal materials and releases gas.

How to Measure Voltage Accurately

To check your phone’s battery voltage:

- Use a multimeter (like the Fluke 117) in DC voltage mode.

- Connect probes to the battery terminals (requires disassembly for some models) or test via the charging port with a USB voltage tester.

- Compare readings to your phone’s specs—e.g., Samsung Galaxy S23 batteries should show ~3.85V at 50% charge.

Pro Tip: Apps like AccuBattery estimate voltage via software, but hardware measurements are more reliable for diagnostics.

How Temperature and Usage Patterns Affect Battery Voltage

The Critical Role of Temperature in Voltage Stability

Battery voltage doesn’t exist in isolation – it’s profoundly affected by environmental temperature. Lithium-ion batteries operate optimally between 15°C to 35°C (59°F to 95°F). Outside this range, you’ll notice significant voltage fluctuations:

- Cold weather (below 10°C/50°F): Chemical reactions slow down, causing temporary voltage drops. Your phone might show 30% charge but suddenly shut down.

- Hot conditions (above 40°C/104°F): Accelerates chemical reactions, showing artificially high voltage readings that quickly plummet when cooled.

How Charging Habits Impact Voltage Longevity

Your daily charging routine directly influences voltage stability over time. Contrary to popular belief, lithium-ion batteries prefer partial charges:

- 80% Rule: Keeping charges between 20-80% reduces voltage stress. Many phones now include “battery protection” modes that cap charging at 85%.

- Fast Charging Effects: While convenient, 9V/12V fast charging generates more heat, causing temporary voltage spikes that degrade battery chemistry faster.

- Overnight Charging: Modern phones stop charging at 100%, but the trickle charging to maintain that level creates small but constant voltage fluctuations.

Practical Voltage Maintenance Tips

Extend your battery’s voltage stability with these professional techniques:

- Seasonal Adjustments: In winter, keep your phone in an inner pocket to maintain optimal operating temperature.

- Charging Cycles: Perform a full 0-100% charge once monthly to recalibrate the voltage monitoring system.

- Storage Preparation: If storing a device long-term, charge to 50% (about 3.7V) to minimize voltage-related degradation.

Expert Insight: Gaming or video recording while charging creates a “double load” scenario where the battery simultaneously charges and discharges, causing unstable voltage that can trigger overheating warnings or unexpected shutdowns.

Advanced Voltage Analysis: Interpreting Battery Health Metrics

Voltage as a Diagnostic Tool for Battery Wear

Experienced technicians use voltage patterns to assess battery health beyond simple charge levels. A healthy lithium-ion battery should maintain:

| State of Charge | Expected Voltage | Warning Signs |

|---|---|---|

| 100% (Fully charged) | 4.20V ± 0.05V | Voltage drops below 4.15V indicates capacity loss |

| 50% (Nominal) | 3.70V ± 0.03V | Fluctuations >0.1V suggest unstable chemistry |

| 20% (Low charge) | 3.50V ± 0.05V | Voltage collapse below 3.4V signals severe degradation |

The Science Behind Voltage Drop Patterns

Three key electrochemical processes affect voltage behavior:

- Internal Resistance Increase: As batteries age, lithium plating forms on electrodes, causing faster voltage drops under load. A 2-year-old phone might show 3.6V at 50% but crash to 3.2V when launching the camera.

- Charge Acceptance Decline: Worn batteries struggle to reach 4.2V, often plateauing at 4.1V during charging while reporting “100%”.

- Recovery Voltage: Healthy batteries should rebound 0.1-0.2V after removing load. Minimal recovery indicates replacement time.

Professional Diagnostic Techniques

Advanced users can perform these voltage tests:

- Load Testing: Measure voltage while running CPU-intensive apps. >0.3V drop indicates excessive internal resistance.

- Charge Curve Analysis: Graph voltage over a full charge cycle. Healthy batteries show smooth S-curves, while degraded ones exhibit erratic spikes.

- Open-Circuit Voltage: Measure after 30 minutes rest. Below 3.3V suggests permanent capacity loss.

Critical Mistake to Avoid: Never judge battery health by voltage alone when cold – lithium-ion batteries exhibit temporary voltage suppression up to 0.3V lower in freezing conditions that normalizes at room temperature.

Voltage Optimization Strategies for Maximum Battery Lifespan

Smart Charging Techniques for Voltage Preservation

Modern lithium-ion batteries thrive on specific voltage maintenance practices that differ significantly from older battery technologies. The most effective approach involves:

- Partial charging cycles: Maintaining battery voltage between 3.4V (20%) and 4.1V (85%) reduces electrode stress. Many flagship phones now include “optimized charging” features that learn usage patterns to complete charging to 100% just before use.

- Temperature-aware charging: Avoid charging when device temperatures exceed 35°C (95°F), as heat causes voltage to spike unpredictably. Use slow charging in hot environments to maintain stable voltage curves.

- Voltage threshold customization: Advanced users can utilize manufacturer diagnostic modes (like Samsung’s Service Mode) to view real-time voltage data and adjust charging behavior accordingly.

Voltage Regulation Circuits

Your phone’s power management IC (PMIC) constantly monitors and adjusts voltage through several protection mechanisms:

- Over-voltage protection (OVP): Automatically cuts off charging if voltage exceeds 4.25V to prevent dangerous pressure buildup

- Under-voltage lockout (UVLO): Forces shutdown when voltage drops below 3.0V to avoid irreversible copper shunt formation

- Dynamic voltage scaling: Adjusts processor voltage (typically 0.8V-1.2V) independently of battery voltage to optimize power efficiency

Professional-Grade Voltage Maintenance Schedule

For optimal long-term voltage stability, follow this monthly maintenance routine:

| Task | Purpose | Voltage Impact |

|---|---|---|

| Full discharge/charge cycle | Recalibrate voltage monitoring system | Resets 3.0V-4.2V detection range |

| Cool-down period | Allow battery to stabilize at room temperature | Normalizes voltage readings by ±0.1V |

| Load test with diagnostic app | Check voltage drop under stress | Reveals internal resistance changes |

Safety Note: When measuring voltage directly with multimeters, always use fused test leads and start with the highest voltage range setting. Lithium-ion batteries can deliver dangerous current if shorted, even at “low” 4.2V levels.

The Future of Battery Voltage Technology and Sustainable Practices

Emerging Voltage Management Technologies

Next-generation battery systems are revolutionizing voltage control with several key advancements:

- Adaptive voltage charging: Newer smartphones like the iPhone 15 Pro and Samsung Galaxy S24 series now feature AI-driven charging that dynamically adjusts voltage based on usage patterns, maintaining optimal 3.8-4.1V ranges for 80% of the charge cycle.

- Solid-state battery voltage profiles: Upcoming solid-state batteries (expected 2026-2028) will operate at higher nominal voltages (4.5-5.0V) while maintaining better stability, potentially doubling energy density.

- Self-healing voltage regulators: Experimental circuits can detect and compensate for voltage fluctuations caused by microscopic battery damage, extending usable life by up to 40%.

Environmental Impact of Voltage Optimization

Proper voltage maintenance directly contributes to sustainability:

| Practice | Voltage Impact | Environmental Benefit |

|---|---|---|

| Optimal charging (20-80%) | Maintains 3.7-4.1V range | Reduces battery replacements by 2-3x |

| Temperature management | Prevents ±0.2V fluctuations | Cuts energy waste by 15-20% |

| Proper disposal at 2.5V | Fully discharges safely | Enables 95% material recovery |

Long-Term Voltage Maintenance Economics

A comprehensive cost-benefit analysis reveals:

- Initial investment: Quality voltage monitoring tools ($50-150) pay for themselves in 6-12 months through extended battery life

- Operational savings: Proper voltage maintenance can delay replacement costs ($80-300) by 18-24 months

- Hidden costs: Voltage-related battery failures account for 23% of premature smartphone replacements according to 2023 industry data

Safety Evolution: New UL 2054 standards require batteries to maintain voltage stability within ±0.05V during extreme condition testing, pushing manufacturers to implement more robust voltage regulation circuits in all consumer devices by 2025.

Advanced Voltage Diagnostics and System Integration

Comprehensive Voltage Troubleshooting Methodology

Professional technicians follow a systematic approach to diagnose voltage-related issues:

- Baseline Measurement: Record open-circuit voltage after 30 minutes of inactivity (should be 3.7V ±0.1V at room temperature)

- Load Testing: Monitor voltage drop during standardized tasks (e.g., 4K video recording should cause ≤0.15V drop on healthy batteries)

- Charge Cycle Analysis: Graph voltage progression during charging (healthy batteries show smooth curve from 3.0V to 4.2V in 90-120 minutes)

Integration with Power Management Systems

Modern smartphones utilize multi-layer voltage regulation:

| Component | Voltage Range | Function |

|---|---|---|

| Battery Cell | 3.0-4.2V | Primary energy storage |

| PMIC | 1.8-3.3V | System power distribution |

| CPU/GPU | 0.6-1.2V | Dynamic voltage scaling |

Specialized Scenarios and Solutions

Addressing unique voltage challenges requires tailored approaches:

- Fast Charging Systems: Qualcomm Quick Charge 5 switches between 3.3V-20V in 200mV increments, requiring precise voltage monitoring

- Wireless Charging:

Inductive systems induce voltage fluctuations that must be filtered by dedicated regulation circuits - Extreme Environments: Aerospace applications use redundant voltage monitoring chips that sample at 1000Hz for critical systems

Optimization Techniques for Power Users

Advanced users can implement these voltage management strategies:

- Use manufacturer diagnostic modes (e.g., *#0228# on Samsung) to view real-time voltage data

- Install kernel-level managers like Franco Kernel to customize voltage-frequency tables

- Implement USB-C voltage triggers to maintain optimal 4.8V input during extended desktop use

Professional Tip: When replacing batteries, always verify the new cell’s voltage matches the old one within 0.05V before installation to prevent system compatibility issues or inaccurate charge reporting.

Mastering Voltage Management: Professional-Grade Optimization and Risk Mitigation

System-Wide Voltage Optimization Framework

Advanced voltage management requires understanding the complete power delivery ecosystem:

| Component | Optimal Voltage | Tolerance Threshold |

|---|---|---|

| Battery Cell | 3.7V nominal | ±0.25V operational |

| Charging Circuit | 5V/9V input | ±5% regulation |

| Processor Cores | 0.8-1.2V dynamic | ±50mV stability |

Comprehensive Risk Assessment Matrix

Professional technicians evaluate voltage-related risks using this severity classification:

- Critical Risks (Immediate Action Required):

- Voltage spikes exceeding 4.3V (thermal runaway risk)

- Sustained operation below 3.0V (copper shunting)

- High Risks (Scheduled Mitigation):

- Consistent 0.3V+ drops under load (impending failure)

- Charging plateau at 4.1V (capacity degradation)

- Monitoring Required:

- 0.1-0.2V seasonal variations (normal operation)

- Brief 4.25V peaks during fast charging (within spec)

Advanced Quality Assurance Protocols

Manufacturer-level voltage validation includes:

- 1000-cycle stress testing: Verifying voltage stability remains within 3.5-4.2V through entire lifespan

- Thermal voltage mapping: Ensuring ≤0.1V deviation across -20°C to 60°C operating range

- Transient response analysis: Measuring recovery time from 4.2V to 3.7V under simulated call load

Long-Term Maintenance Strategy

Implement this 6-month voltage health check protocol:

- Perform full discharge-charge cycle to reset voltage counters

- Measure resting voltage after 2 hours (should be 3.7V ±0.05V)

- Test under 50% load (gaming benchmark) for ≤0.2V drop

- Verify charging completes to 4.2V within manufacturer specs

Professional Insight: High-end diagnostic tools like the Batronix Battery Analyzer can predict remaining lifespan with 95% accuracy by analyzing micro-voltage fluctuations during charge cycles, revealing degradation patterns invisible to standard testing.

Conclusion: Mastering Phone Battery Voltage for Optimal Performance

Understanding your phone’s battery voltage is the key to maximizing both performance and lifespan. Throughout this guide, we’ve explored the critical voltage ranges (3.0V-4.2V), how temperature and usage patterns affect stability, advanced diagnostic techniques, and professional optimization strategies.

You’ve learned to interpret voltage readings as vital health indicators, implement smart charging practices, and troubleshoot common voltage-related issues.

Put this knowledge into action today: Start by checking your current battery voltage using a multimeter or diagnostic app, then establish proper charging habits. Remember, consistent voltage monitoring can extend your battery’s life by years.

Frequently Asked Questions About Phone Battery Voltage

What is the normal voltage range for a smartphone battery?

A healthy lithium-ion phone battery operates between 3.0V (fully discharged) and 4.2V (fully charged), with 3.7V being the nominal voltage.

Most manufacturers design protection circuits to prevent operation outside this range. For example, iPhones automatically shut down at 3.2V to prevent deep discharge damage, while Samsung devices typically charge to 4.35V for extended capacity.

How can I accurately measure my phone’s battery voltage?

You’ll need a digital multimeter set to DC voltage mode. For direct measurement (requires battery access):

- Power off the device and remove the battery if possible

- Connect red probe to positive terminal, black to negative

- Read voltage display (should be 3.3-4.2V for usable charge)

For non-removable batteries, use USB voltage testers or diagnostic apps like AccuBattery (less precise).

Why does my phone battery voltage drop suddenly in cold weather?

Cold temperatures (<10°C/50°F) slow electrochemical reactions in lithium-ion batteries, causing temporary voltage suppression of 0.2-0.3V. This isn’t permanent damage – the voltage recovers when warmed.

For example, your phone might show 3.5V at 20% in cold weather but rebound to 3.8V at room temperature. Extreme cold (<0°C/32°F) can trigger premature shutdowns as protection circuits activate.

How does fast charging affect battery voltage over time?

Fast charging (9V/12V) creates higher voltage stress through:

- Increased heat generation (reduces electrolyte stability)

- More aggressive lithium plating (raises internal resistance)

- Voltage spikes during charge cycle transitions

After 300 fast-charge cycles, you might notice 0.1-0.15V lower maximum voltage capacity. Using standard 5V charging 2-3 times weekly helps maintain voltage stability.

What voltage indicates I need to replace my phone battery?

Watch for these warning signs:

- Fully charged voltage below 4.15V (normal is 4.2V)

- 20% charge reading below 3.5V

- Voltage drops >0.3V under moderate load

- Inability to reach 4.0V during charging

For context, a 2-year-old battery typically shows 4.1V at “full” charge and 3.4V at 20%.

Is it safe to use third-party chargers with different voltage outputs?

Quality third-party chargers with proper USB-IF certification are generally safe as modern phones negotiate voltage through the USB Power Delivery protocol. However, uncertified chargers may:

- Deliver unstable voltage (spikes above 5.5V can damage circuits)

- Fail to step down properly during trickle charging

- Lack over-voltage protection (risk of exceeding 4.25V battery input)

Always verify the charger outputs exactly 5V/9V as labeled.

How does battery voltage affect my phone’s performance?

Voltage directly impacts performance through:

| Voltage Range | Performance Impact |

|---|---|

| 4.1-4.2V | Peak CPU/GPU performance |

| 3.7-4.0V | Normal operation |

| 3.4-3.6V | Possible throttling |

| <3.4V | Emergency power saving mode |

This explains why phones feel slower at low charge – processors reduce clock speeds to maintain stability.

Can I revive a phone battery that won’t hold voltage?

For batteries reading below 2.5V, recovery is unlikely due to copper shunting. For marginal cases (2.8-3.0V):

- Use a specialized lithium-ion charger with “wake-up” mode

- Apply 0.1C current (50mA for 500mAh battery) for 1 hour

- Monitor for voltage rise above 3.2V

Note that even successful revival typically results in 30-50% capacity loss. Professional battery analyzers can assess true remaining capacity.