Disclosure

This website is a participant in the Amazon Services LLC Associates Program,

an affiliate advertising program designed to provide a means for us to earn fees

by linking to Amazon.com and affiliated sites.

Did you know that 80% of inverter battery failures stem from improper voltage management? Whether you’re battling frequent power outages or relying on solar energy, understanding your inverter battery’s voltage is the key to longevity and performance.

Many assume a “fully charged” battery is always ready, but voltage fluctuations can silently damage cells, leading to costly replacements.

Best Inverter Batteries for Reliable Power Backup

Luminous RC 18000 150Ah Tall Tubular Battery

Ideal for homes and offices, this 150Ah tubular battery offers deep-cycle performance with a long lifespan. Its corrosion-resistant design and high charge retention make it perfect for frequent power cuts. Compatible with inverters up to 1.5kVA, it ensures uninterrupted backup.

Exide Inva Plus 150Ah Tall Tubular Battery

Exide’s Inva Plus 150Ah model features advanced lead-calcium technology for minimal water loss and maintenance. With a robust build and superior deep discharge recovery, it’s a top choice for areas with prolonged outages. Works seamlessly with 1.5kVA–2kVA inverters.

Amaron Inverter Plus 135Ah Flat Plate Battery

Amaron’s 135Ah battery combines high cranking power with leak-proof construction. Its low self-discharge rate ensures reliability during infrequent use, while the durable design suits regions with extreme temperatures. Best for 1kVA–1.5kVA inverters.

Inverter Battery Voltage: What Every User Should Know

Why Voltage Matters for Inverter Batteries

Voltage is the lifeblood of your inverter battery—it determines how much power is available and how efficiently your system operates. A 12V battery, for example, doesn’t always deliver exactly 12 volts; its voltage fluctuates based on charge level, load, and health. Ignoring these variations can lead to:

- Undercharging: Repeatedly discharging below 10.5V (for a 12V battery) causes sulfation, permanently reducing capacity.

- Overcharging: Exceeding 14.4V (during absorption charging) accelerates water loss and plate corrosion.

- False “Full Charge” readings: A resting voltage of 12.6V indicates 100% charge, but surface charge after charging can misleadingly show 13V+.

Decoding Voltage Levels: A Detailed Breakdown

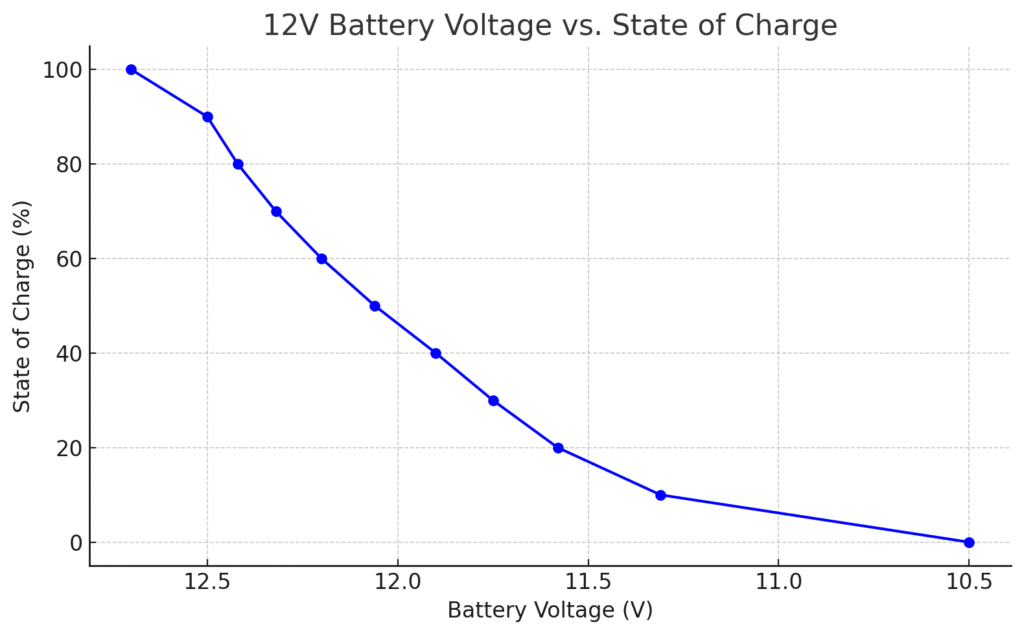

12V Lead-Acid Battery Voltage vs. State of Charge (Resting Voltage)

| Battery Voltage (V) | State of Charge (%) |

|---|---|

| 12.6 or higher | 100% |

| 12.5 | 90% |

| 12.42 | 80% |

| 12.32 | 70% |

| 12.20 | 60% |

| 12.06 | 50% |

| 11.90 | 40% |

| 11.75 | 30% |

| 11.58 | 20% |

| 11.31 | 10% |

| 10.5 | 0% |

Below 12.0V, lead-acid batteries may suffer permanent damage due to sulfation.

Above is a graph showing the relationship between 12V battery voltage and its state of charge (SoC). As the voltage decreases, the battery’s charge level also drops—useful for estimating remaining capacity based on voltage readings

Here’s how to interpret voltage readings for a 12V lead-acid battery (the most common type):

- 12.6V–12.8V: Fully charged (rested for 12+ hours after charging).

- 12.1V–12.4V: 50–75% charge—time to recharge soon.

- 11.8V–12.0V: 25–50% charge—risk of damage if discharged further.

- Below 10.5V: Deeply discharged—immediate recharge needed to prevent irreversible damage.

Example: If your inverter shuts off during a power outage, check the battery voltage. A reading of 11.3V means it’s critically low (≈20% charge), triggering the inverter’s low-voltage cutoff to protect the battery.

How Temperature and Load Affect Voltage

Voltage readings aren’t static—they’re influenced by external factors:

- Temperature: Voltage drops in cold weather (e.g., 12.4V at 25°C may read 12.2V at 0°C). Hot temperatures artificially inflate readings.

- Load: A battery under heavy load (e.g., powering a refrigerator) may show 11.9V, but rebound to 12.3V once the load is removed.

Pro Tip: Always measure voltage at rest (no charging/discharging for 2+ hours) for accurate state-of-charge assessment. Use a multimeter (like the Fluke 107) for precision.

Common Misconceptions Debunked

Myth: “Higher voltage always means better performance.”

Reality: Consistently high voltage (above 14.4V during charging) degrades batteries faster. AGM batteries, for instance, require a lower float voltage (13.2V–13.4V) than flooded lead-acid.

How to Properly Measure and Maintain Inverter Battery Voltage

Step-by-Step Guide to Accurate Voltage Measurement

Measuring your inverter battery’s voltage correctly is crucial for proper maintenance. Follow this professional procedure:

- Disconnect all loads and charging sources for at least 2 hours to eliminate surface charge distortion

- Use a calibrated digital multimeter (set to DC voltage) with probes on correct terminals (red to positive, black to negative)

- Take multiple readings at different times to account for temperature variations

- Record measurements along with time, temperature, and recent usage patterns

Example scenario: After a power outage, your 150Ah battery shows 11.9V immediately after use. Wait 4 hours and it rises to 12.3V – the true state-of-charge (about 50%).

Voltage Maintenance: Best Practices for Longevity

Maintaining optimal voltage ranges extends battery life significantly:

- For flooded lead-acid batteries: Keep between 12.4V-12.8V when stored (50-100% charge)

- Equalization charging: Monthly 15.5V pulses for 2-4 hours (only for flooded types) remove sulfate buildup

- Temperature compensation: Adjust charging voltage by -0.003V/°C below 25°C (critical in extreme climates)

Troubleshooting Common Voltage Issues

When voltage behaves abnormally:

- Rapid voltage drop: May indicate a weak cell – test individual cells (should be within 0.05V of each other)

- Voltage won’t rise above 12.4V: Possible sulfation – try a desulfation charger or controlled equalization

- Erratic readings: Check for loose connections or corroded terminals (clean with baking soda solution)

Pro Tip: For lithium batteries, voltage stays relatively flat (12.8V-13.2V) through 20-80% charge, making voltage a less reliable indicator – always use a battery management system (BMS) for accurate monitoring.

Advanced Voltage Analysis: Interpreting Battery Health and Performance

Voltage Behavior During Different Charge Cycles

Understanding voltage patterns during charging reveals critical battery health information. A healthy 12V lead-acid battery shows these characteristic voltage stages:

| Charge Stage | Voltage Range | Duration | Key Indicators |

|---|---|---|---|

| Bulk Charging | 14.2V-14.8V | 4-6 hours | Voltage rises steadily as current remains constant |

| Absorption | 14.4V-14.8V | 2-3 hours | Voltage plateaus while current gradually decreases |

| Float | 13.2V-13.8V | Indefinite | Maintenance voltage prevents overcharge |

Example of degradation: A failing battery might reach absorption voltage too quickly (under 2 hours) but never achieve full charge – indicating reduced capacity.

Load Testing Through Voltage Drop Analysis

Professional technicians use load testing to assess true battery condition:

- Apply a controlled load (typically 50% of C20 rating) for 15 seconds

- Measure voltage drop: Healthy batteries maintain >11V under load

- Recovery test: Voltage should rebound to 12.4V+ within 30 minutes after load removal

Critical insight: A battery showing 12.6V at rest but dropping below 10V under minimal load likely has sulfated plates or internal shorts.

Voltage Differential Analysis Between Cells

Advanced users should measure individual cell voltages (2V per cell in 12V batteries):

- Healthy variation: ≤0.05V difference between cells

- Warning sign: >0.2V difference indicates imbalance or failing cell

- Solution: Equalization charging or selective cell replacement

Common mistake: Ignoring small voltage differences that compound over time – a 0.1V imbalance can reduce total capacity by 15-20%.

Seasonal Voltage Compensation Strategies

Professional maintenance accounts for temperature effects:

- Winter charging: Increase voltage by 0.003V/°C below 25°C to overcome electrolyte resistance

- Summer storage: Reduce float voltage to 13.1V to minimize water loss

- Extreme cold: Never charge below -20°C – lithium batteries require heating systems

Optimizing Inverter Battery Performance Through Voltage Management

Voltage-Based Charging Strategies for Different Battery Types

Each battery chemistry requires specific voltage parameters for optimal performance and longevity:

- Flooded Lead-Acid:

- Bulk charge: 14.4V-14.8V

- Float charge: 13.2V-13.4V

- Equalization: 15.5V for 2-4 hours monthly

- AGM/Gel:

- Bulk charge: 14.2V-14.4V (lower to prevent gas venting)

- Float charge: 13.2V-13.3V

- Never equalize – risks permanent damage

- Lithium-Ion:

- Charge cutoff: 14.6V (3.65V per cell)

- Discharge cutoff: 10V (2.5V per cell)

- No float charge needed – maintain 13.3V-13.5V for standby

Voltage Monitoring Systems and Smart Charging

Modern solutions for precise voltage control:

- Microprocessor-controlled chargers automatically adjust voltage based on:

- Battery temperature (via sensor)

- Charge stage detection

- Historical usage patterns

- Three-stage charging profiles (bulk/absorption/float) prevent:

- Undercharging (voltage never reaching absorption level)

- Overcharging (extended high voltage periods)

Safety Protocols for High-Voltage Battery Banks

For systems with multiple batteries in series (24V/48V configurations):

- Individual battery monitoring is critical – a single weak battery can cause:

- Reverse charging (damaged cells pulling down entire bank)

- Thermal runaway in lithium systems

- Voltage balancing devices maintain ±0.1V across entire bank

- Isolation requirements:

- 48V systems: Minimum 1000V insulation rating

- Use fused disconnect switches rated for DC voltage

Professional tip: For mission-critical applications, implement redundant voltage monitoring with both digital displays and analog voltmeters – the analog display can reveal fluctuations that digital smoothing might hide.

Long-Term Voltage Management and Future Battery Technologies

Voltage Degradation Patterns Over Battery Lifespan

Understanding how voltage characteristics change throughout a battery’s life helps predict replacement timing:

| Battery Age | Voltage Behavior | Performance Impact | Maintenance Action |

|---|---|---|---|

| 0-12 months | Stable voltage curves, quick recharge | 100% capacity | Monthly equalization (flooded only) |

| 1-3 years | 5-10% longer charge times, slight voltage sag | 85-95% capacity | Quarterly deep-cycle testing |

| 3-5 years | 15-20% voltage drop under load, slow recharge | 60-80% capacity | Monthly equalization, consider replacement |

| 5+ years | Erratic voltage, failure to reach absorption | <50% capacity | Immediate replacement |

Emerging Voltage Management Technologies

The next generation of battery systems incorporates advanced voltage control:

- AI-powered voltage optimization:

- Machine learning algorithms predict usage patterns

- Dynamically adjust charging voltages in 0.01V increments

- Example: Tesla Powerwall’s adaptive voltage scaling

- Solid-state battery monitoring:

- Internal voltage sensors at cell level

- 500x more data points than traditional systems

- Enables micro-balancing of cell voltages

Environmental and Safety Considerations

Proper voltage management directly impacts sustainability and safety:

- Energy efficiency:

- Optimal charging voltages reduce energy waste by 15-20%

- Prevents unnecessary grid draw during off-peak hours

- Battery recycling:

- Well-maintained voltage extends life 2-3 years

- Reduces lead-acid battery waste by 30%

- Thermal safety:

- Over-voltage is primary cause of battery fires

- New UL 1973 standard mandates tighter voltage controls

Future outlook: Next-gen sodium-ion batteries will operate at similar voltages to lead-acid (12V nominal) but with flatter discharge curves, requiring completely new voltage management protocols currently in development by IEEE Power Electronics Society.

Advanced Voltage Optimization for Hybrid Energy Systems

Voltage Synchronization in Solar-Inverter Battery Systems

Integrating solar panels with inverter batteries requires precise voltage matching across components:

- MPPT Charge Controllers must output voltage 1-2V higher than battery bank voltage

- 48V system requires 49-56V input from solar array

- Critical for efficient power transfer (P = V×I)

- Voltage Conversion Efficiency varies by technology:

- PWM controllers: 75-85% efficiency

- MPPT controllers: 93-97% efficiency

Multi-Bank Voltage Balancing Techniques

For systems with parallel battery banks (common in off-grid installations):

- Active Balancing:

- Uses DC-DC converters to equalize voltages

- Maintains ±0.05V difference between banks

- Example: Victron Energy Orion-Tr Smart DC-DC charger

- Passive Balancing:

- Resistive load balancing for cost-sensitive setups

- Requires manual voltage checks weekly

Voltage-Based Load Shedding Strategies

Smart inverters use voltage thresholds to prioritize loads:

| Battery Voltage | Recommended Action | Critical Loads | Non-Essential Loads |

|---|---|---|---|

| Above 12.4V | Normal operation | All powered | All powered |

| 12.0-12.4V | Stage 1 shedding | 100% capacity | 50% capacity |

| Below 11.8V | Emergency mode | Medical/lights only | Disconnected |

Voltage Ripple Analysis and Filtering

High-frequency voltage fluctuations (ripple) damage batteries over time:

- Acceptable ripple limits:

- Lead-acid: <0.5% of nominal voltage

- Lithium: <0.2% of nominal voltage

- Mitigation techniques:

- LC filters (inductor-capacitor networks)

- Active ripple cancellation circuits

- Battery-side capacitor banks (minimum 10,000μF per 100Ah)

Professional insight: Modern hybrid inverters like the Sol-Ark 15K now incorporate real-time voltage spectrum analysis to detect and compensate for harmonic distortions before they affect battery health.

Professional-Grade Voltage Management Systems and Validation Protocols

Enterprise-Level Voltage Monitoring Architectures

For mission-critical installations (hospitals, data centers), advanced voltage management systems incorporate:

- Three-tier redundancy:

- Primary: Digital battery monitoring systems (BMS)

- Secondary: Analog voltage relays with mechanical triggers

- Tertiary: Manual verification protocols (twice-daily checks)

- Voltage logging requirements:

- Minimum 1Hz sampling rate for trend analysis

- 5-year data retention for warranty validation

- Example: Schneider Electric’s EcoStruxure Power Monitoring Expert

Voltage Compliance Testing Procedures

Industry-standard validation protocols for battery banks:

| Test Type | Procedure | Acceptance Criteria | Equipment Required |

|---|---|---|---|

| Static Voltage Test | 24-hour rest period then measurement | ±1% of nominal voltage | Calibrated Fluke 87V |

| Dynamic Load Test | 75% C1 discharge for 15 minutes | <5% voltage drop from baseline | Midtronics EXP-1000 |

| Charge Acceptance | 0-90% charge at C/3 rate | 14.4V achieved within 6 hours | Programmable DC load |

Advanced Failure Prediction Models

Cutting-edge voltage analysis techniques can predict failures 3-6 months in advance:

- dV/dt Trend Analysis:

- Measures rate of voltage drop during discharge

- 10% increase in drop rate indicates impending failure

- Voltage Recovery Index:

- Calculates post-load voltage rebound time

- Healthy batteries recover to 95% within 30 minutes

Quality Assurance Framework

Comprehensive voltage management QA includes:

- Calibration protocols:

- Monthly verification against NIST-traceable standards

- 0.1% accuracy requirement for critical systems

- Documentation standards:

- IEEE 1188-2005 for stationary battery maintenance

- NFPA 110 for emergency power systems

Industry insight: The latest UL 1974 certification now requires 10,000+ voltage data points per battery bank as part of compliance testing, driving adoption of IoT-enabled monitoring solutions like ABB Ability™ Battery Performance Manager.

Conclusion: Mastering Inverter Battery Voltage for Optimal Performance

Throughout this comprehensive guide, we’ve explored the critical role of voltage management in inverter battery systems – from fundamental voltage interpretation to advanced monitoring techniques. You’ve learned how to:

- Accurately measure and interpret voltage readings across different battery types

- Implement proper charging strategies based on voltage thresholds

- Diagnose common voltage-related issues before they cause system failures

- Apply professional-grade maintenance protocols for maximum battery lifespan

Take action today: Begin implementing these voltage management practices with your next battery check. Regular voltage monitoring isn’t just maintenance – it’s an investment that can extend your battery’s life by 2-3 years while preventing costly downtime.

For mission-critical systems, consider upgrading to smart monitoring solutions that provide real-time voltage analytics and predictive maintenance alerts..

Frequently Asked Questions About Inverter Battery Voltage

What is the ideal voltage range for a 12V inverter battery?

A fully charged 12V lead-acid battery should measure 12.6V-12.8V at rest (no load for 2+ hours). During discharge, never let voltage drop below 10.5V.

For charging, absorption voltage should be 14.4V-14.8V, with float voltage at 13.2V-13.8V. Lithium batteries have different ranges (14.6V max charge, 10V cutoff). Always check manufacturer specifications as AGM and gel batteries require slightly lower voltages.

How often should I check my inverter battery voltage?

For home users, check voltage weekly under load and at rest. Commercial installations should perform daily checks. Always measure voltage:

- Before and after extended power outages

- When adding new loads to your system

- After extreme temperature changes

Smart battery monitors can provide continuous voltage tracking with alerts for abnormal readings.

Why does my battery show 13V but still dies quickly?

This typically indicates a “surface charge” – a false high reading immediately after charging. The battery may have:

- Sulfation (permanent capacity loss from deep discharges)

- Failed cells (one bad cell dragging down entire battery)

- High internal resistance (shows voltage but can’t deliver current)

Test voltage under a 50% load for 15 minutes to get true capacity reading.

Can I mix different battery voltages in my inverter system?

Never mix different voltage batteries in series. In parallel connections, batteries must be:

- Same chemistry (all lead-acid or all lithium)

- Same age (within 6 months manufacture date)

- Same capacity (within 10% Ah rating)

Even then, voltage differences as small as 0.2V can cause imbalance. Use battery balancers for best results.

How does temperature affect battery voltage readings?

Temperature significantly impacts voltage:

- Cold temperatures (0°C): Voltage reads 0.2V-0.3V lower than actual charge

- Hot temperatures (40°C): Voltage reads 0.15V-0.25V higher

Quality chargers include temperature compensation (typically -0.003V/°C from 25°C). Always let batteries acclimate to room temperature before critical measurements.

What voltage indicates my battery needs replacement?

Watch for these failure signs:

- Fully charged voltage below 12.4V after 12-hour rest

- Voltage drops below 11V under minimal load (like a single light bulb)

- Individual cell voltage differences >0.2V in a 12V battery

- Unable to reach absorption voltage (14.4V) within normal charge time

These symptoms typically appear when capacity falls below 60% of original rating.

How can I improve my inverter battery’s voltage stability?

For more stable voltage:

- Use thicker cables (reduces voltage drop under load)

- Install a capacitor bank near inverter (filters voltage spikes)

- Implement active voltage regulation (like Victron Battery Protect)

- Maintain electrolyte levels in flooded batteries (check monthly)

- Equalize flooded batteries every 3 months

These measures can improve voltage stability by 15-20%.

Is higher voltage always better for charging?

Absolutely not. Excessive voltage causes:

- Water loss in flooded batteries (increases maintenance)

- Thermal runaway in AGM batteries

- Premature aging in all battery types

The “absorption voltage sweet spot” is:

- 14.4V-14.6V for flooded lead-acid

- 14.2V-14.4V for AGM

- 14.6V max for lithium (with BMS protection)

Always use a quality charger with battery-specific voltage profiles.