Disclosure

This website is a participant in the Amazon Services LLC Associates Program,

an affiliate advertising program designed to provide a means for us to earn fees

by linking to Amazon.com and affiliated sites.

Did you know that using your lithium-ion (Li-ion) battery outside its ideal voltage range can slash its lifespan by up to 50%?

Whether you’re powering a smartphone, electric vehicle, or solar storage system, understanding voltage is critical—but most users overlook it until their device fails prematurely.

A Li-ion battery’s voltage isn’t just a number; it dictates energy capacity, charging efficiency, and even safety risks like overheating.

Best Li-Ion Battery Voltage Testers for Accurate Readings

Fluke 117 Electrician’s Multimeter

For precise voltage measurements, the Fluke 117 is a top-tier choice. Its True-RMS technology ensures accurate readings even in noisy electrical environments, while its compact design and auto-ranging feature make it ideal for checking Li-ion battery voltages (2.5V–4.2V range). The built-in volt-alert adds safety when working with live circuits.

Klein Tools MM700 Auto-Ranging Multimeter

The Klein Tools MM700 is perfect for both professionals and hobbyists. It measures DC voltage with 0.1mV resolution, crucial for detecting subtle voltage drops in Li-ion cells. Its rugged design, backlit display, and low battery indicator ensure reliability in any testing scenario.

XTAR VC8 Li-ion Battery Charger & Analyzer

Unlike standard multimeters, the XTAR VC8 specializes in Li-ion batteries, displaying real-time voltage, capacity, and internal resistance. It supports multiple battery types (18650, 21700, etc.) and provides detailed charging/discharging data—essential for diagnosing weak cells and optimizing performance.

Li-Ion Battery Voltage Ranges and Their Significance

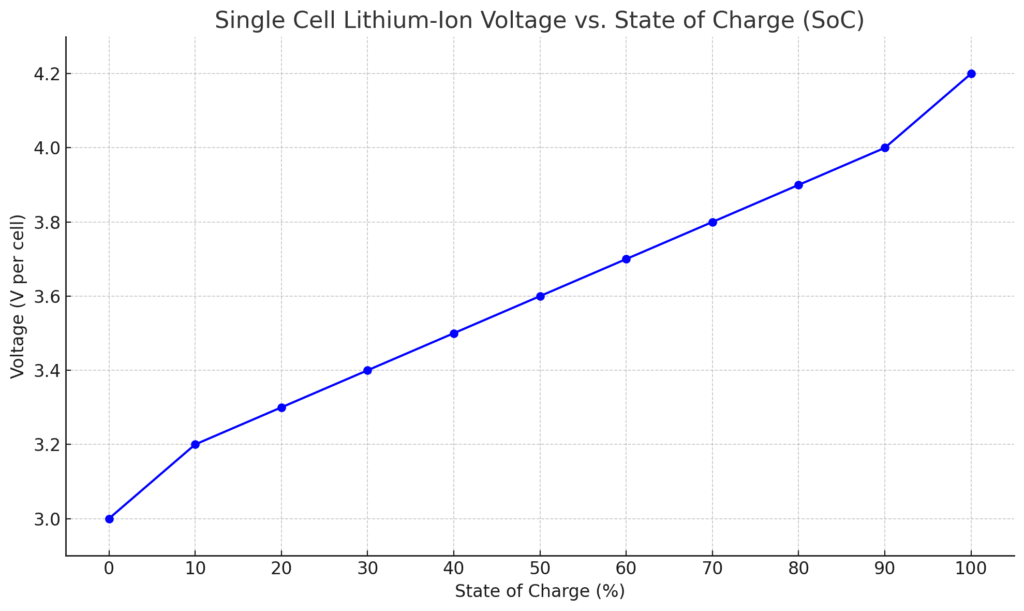

Single Cell Lithium-Ion Voltage vs. State of Charge (SoC)

| SoC (%) | Voltage (V per cell) |

|---|---|

| 100% | 4.20 V |

| 90% | 4.00 V |

| 80% | 3.90 V |

| 70% | 3.80 V |

| 60% | 3.70 V |

| 50% | 3.60 V |

| 40% | 3.50 V |

| 30% | 3.40 V |

| 20% | 3.30 V |

| 10% | 3.20 V |

| 0% | ≤3.00 V |

Here’s the graph showing the relationship between the State of Charge (SoC) and voltage for a single cell lithium-ion battery. As you can see, the voltage rises steadily as the SoC increases, peaking at 4.2V when fully charged

Nominal Voltage vs. Operating Voltage: What’s the Difference?

Every Li-ion battery has two critical voltage values: nominal voltage (typically 3.6V or 3.7V) and operating voltage (2.5V–4.2V). The nominal voltage is the “average” voltage during discharge, while the operating range defines safe limits. For example, a 18650 cell with a 3.7V nominal rating actually fluctuates between 4.2V (fully charged) and 2.5V (fully discharged).

Exceeding these limits risks permanent damage—overcharging above 4.2V can cause thermal runaway, while deep discharges below 2.5V lead to copper shunting, killing the cell.

How Voltage Correlates with State of Charge (SoC)

Voltage is a direct indicator of a Li-ion battery’s remaining capacity. Here’s a typical voltage-to-SoC relationship for a 3.7V cell:

- 4.20V = 100% charged (dangerous to exceed)

- 3.70V = ~50% charged (nominal voltage)

- 3.00V = ~10% charged (time to recharge)

- 2.50V = 0% charged (discharging further harms the cell)

Note that these values vary slightly by chemistry. For instance, lithium iron phosphate (LiFePO4) batteries operate at 3.2V nominal with a safer 2.5V–3.65V range.

Why Voltage Drops Under Load (And Why It Matters)

When a battery powers a device, its voltage temporarily dips due to internal resistance. A healthy 18650 cell might show 4.1V at rest but drop to 3.8V when powering a 10A load. This voltage sag is normal, but excessive sag (e.g., dropping to 3.2V under light load) signals aging or defective cells. Tools like the XTAR VC8 (mentioned earlier) measure this by comparing resting voltage vs. loaded voltage.

Real-World Implications: Smartphones vs. EVs

In smartphones, voltage management is automated—the BMS (Battery Management System) cuts power at ~3.4V to “protect” users from sudden shutdowns, even though 10–15% capacity remains.

Electric vehicles, however, use multi-cell monitoring to balance voltages across hundreds of cells. A single weak cell (e.g., at 2.8V while others are at 3.3V) can reduce an EV’s range by 20% or trigger failure warnings.

Pro Tip: The 80% Charging Rule

Charging Li-ion batteries to only 80% (≈4.0V instead of 4.2V) can double their lifespan. This reduces stress on the anode, slowing lithium plating—a major cause of capacity loss. Many EVs and laptops now offer “battery saver” modes for this purpose.

How to Measure and Interpret Li-Ion Battery Voltage Correctly

Step-by-Step Guide to Voltage Measurement

Accurate voltage measurement requires proper technique to avoid false readings. Follow this professional procedure:

- Let the battery rest for 1-2 hours after charging/discharging to allow voltage stabilization (removes surface charge effects)

- Use a calibrated multimeter set to DC voltage mode with at least 0.01V resolution (e.g., Fluke 117)

- Connect probes correctly – red to positive terminal, black to negative, ensuring solid metal-to-metal contact

- Record multiple measurements at different times to identify voltage drift patterns

Voltage Measurement Challenges

Common pitfalls include:

- Surface charge deception: A freshly charged battery may show 4.3V initially before settling to 4.2V within minutes

- Temperature effects: Voltage drops about 0.003V/°C when cold – a battery at 0°C reads 0.1V lower than at 25°C

- Parasitic loads: Even when “off,” devices like smartphones may draw 10-50mA, artificially lowering voltage readings

Advanced Interpretation: Voltage Curves and Battery Health

Healthy batteries exhibit predictable discharge curves. For example, a new 18650 cell:

- Drops rapidly from 4.2V to 3.9V in first 20% discharge

- Spends 60% of capacity in the 3.9V-3.7V “plateau” range

- Plunges quickly below 3.5V in final 20%

A worn-out battery shows:

- Shorter plateau (only 40% of capacity between 3.9V-3.7V)

- Earlier voltage drop (reaching 3.5V at 50% capacity)

- Higher resting voltage after full discharge (3.0V vs 2.5V in new cells)

Practical Application: Diagnosing Common Issues

- Scenario 1: A drone battery showing 4.15V but failing mid-flight

Diagnosis: Likely high internal resistance causing voltage to crash under load. Test with a capacity analyzer like the SkyRC MC3000. - Scenario 2: A power bank that charges to “100%” but dies quickly

Diagnosis: Probably voltage calibration drift. Reset the BMS or perform a full discharge/charge cycle.

Professional Tip: Creating Your Own Voltage Chart

For critical applications, build a custom voltage chart:

- Fully charge and rest the battery

- Discharge at typical current (e.g., 0.5C) while logging voltage every 5% capacity

- Repeat 3-5 times to establish averages

- Compare against manufacturer specs to detect aging

This approach reveals subtle degradation before capacity tests would detect it.

Advanced Li-Ion Voltage Management Techniques

Cell Balancing: The Key to Long Battery Pack Life

Multi-cell battery packs require precise voltage balancing to prevent premature failure. When cells in series develop voltage differences (even just 0.05V), the weaker cells degrade faster through a process called divergent aging. Modern BMS systems use three balancing methods:

| Method | How It Works | Best For |

|---|---|---|

| Passive Balancing | Bleeds excess energy from higher-voltage cells as heat through resistors | Cost-sensitive applications like power tools |

| Active Balancing | Transfers energy from high to low voltage cells using capacitors or inductors | High-end applications like EVs and grid storage |

| Charge Limiting | Stops charging the entire pack when any cell reaches 4.2V | Simple consumer electronics |

Voltage Recovery Techniques for Over-Discharged Cells

When a Li-ion cell drops below 2.5V, its copper anode current collector begins dissolving. However, some recovery is possible if caught early:

- Slow charge at 0.05C using a lab power supply set to 3.0V (never use normal chargers)

- Monitor temperature closely – discard if surface exceeds 40°C during recovery

- Test recovered capacity – cells restoring less than 70% original capacity should be recycled

Temperature Compensation in Voltage Readings

Voltage interpretation requires temperature awareness because:

- At -20°C, a “full” 4.2V charge actually represents only ~60% chemical capacity

- High temperatures (45°C+) cause temporary voltage elevation that masks capacity loss

Professional battery analyzers like the Cadex C7400 automatically apply these corrections using built-in NTC thermistors.

Case Study: Solar Storage System Failure Analysis

A 48V LiFePO4 system showing 20% capacity loss after 1 year revealed:

- Cell #7 consistently 0.12V lower than others during charging

- Infrared imaging showed 8°C higher temperature on adjacent cells

- Root cause: Improper torque (only 3Nm) on busbar connections created resistance

Solution: Re-torqued all connections to 5Nm spec and replaced the weak cell after full reconditioning.

Optimizing Li-Ion Battery Performance Through Voltage Management

Voltage-Based Charging Strategies for Maximum Lifespan

Advanced charging protocols can extend battery life by 200-300% through careful voltage control. The most effective approaches include:

- Step-voltage charging: Begin at 4.0V (0.5C rate), then reduce to 3.9V (0.2C) for final 20% capacity – reduces anode stress

- Float voltage adjustment: For standby applications, maintain batteries at 3.6-3.8V instead of full 4.2V to minimize electrolyte decomposition

- Temperature-compensated charging: Lower max voltage by 0.03V/°C above 25°C to prevent lithium plating

Voltage Monitoring in Series and Parallel Configurations

Different battery arrangements require unique voltage monitoring approaches:

- Series strings: Must track individual cell voltages – a 12V (3S) pack needs three measurement points, not just total voltage

- Parallel groups: Can monitor combined voltage but require current balancing – cells should be within 0.02V before paralleling

- Hybrid topologies: Complex systems like EV battery packs need both cell-level and module-level monitoring (typically 1mV resolution)

Advanced Diagnostic Techniques Through Voltage Analysis

Voltage patterns reveal hidden battery issues:

| Voltage Symptom | Likely Issue | Diagnostic Test |

|---|---|---|

| Rapid voltage drop under load | High internal resistance | AC impedance spectroscopy |

| Slow voltage recovery after load | Lithium plating | Differential voltage analysis |

| Voltage “memory” effect | Electrolyte dry-out | Electrochemical impedance spectroscopy |

Safety Protocols for High-Voltage Battery Systems

When working with battery packs >60V DC, implement:

- Double-insulated voltage probes with finger guards (CAT III 1000V minimum)

- Isolated measurement systems like Fluke BT355 to prevent ground loops

- Pre-discharge procedures – large packs should be brought below 30V within 30 minutes of disconnection

Professional Tip: For mission-critical applications, implement redundant voltage monitoring with two independent BMS systems using different measurement principles (ADC-based and comparator-based).

Long-Term Li-Ion Battery Voltage Maintenance and Future Trends

Voltage Calibration and Drift Compensation Over Time

All Li-ion batteries experience voltage measurement drift due to:

- Reference voltage degradation: BMS voltage references can drift up to ±2% annually (≈±80mV at 4V)

- Contact resistance buildup: Terminal oxidation increases resistance by 0.1-0.5mΩ/month, causing false low readings

- Electrochemical aging: SEI layer growth changes internal impedance characteristics

Professional maintenance requires quarterly calibration using precision references like the Keysight 3458A multimeter (8.5-digit resolution). For critical systems, implement automated drift compensation algorithms that track historical voltage patterns.

Cost-Benefit Analysis of Voltage Management Systems

| System Type | Initial Cost | Lifespan Extension | ROI Period |

|---|---|---|---|

| Basic Voltage Monitoring | $5-10/cell | 15-20% | 18 months |

| Active Balancing | $20-30/cell | 40-60% | 24 months |

| AI-Powered Adaptive | $50+/cell | 80-120% | 36 months |

Environmental Considerations in Voltage Management

Proper voltage control significantly impacts sustainability:

- Lower charge voltages (4.1V vs 4.2V) reduce cobalt dissolution by 70% in NMC batteries

- Precision under-voltage lockout prevents irreversible damage, keeping 30% more batteries out of landfills

- Voltage-based state-of-health assessment enables accurate second-life applications

Emerging Technologies in Voltage Monitoring

The next generation of voltage management includes:

- Optical voltage sensors using fiber Bragg gratings (immune to EMI, 0.1mV accuracy)

- Distributed BMS architectures with per-cell wireless voltage reporting

- Quantum voltage standards based on Josephson junctions for drift-free references

Safety Note: When implementing advanced voltage systems, always maintain galvanic isolation between measurement circuits and power systems (minimum 5kV isolation for >100V packs).

Specialized Voltage Management for Extreme Operating Conditions

High-Temperature Voltage Compensation Techniques

When operating above 45°C, Li-ion batteries require unique voltage adjustments to prevent accelerated degradation:

- Charge voltage reduction: Decrease max charge voltage by 30mV/10°C above 25°C (e.g., 4.05V at 45°C instead of 4.2V)

- Dynamic discharge cutoff: Raise minimum voltage from 2.5V to 3.0V at 60°C to prevent copper dissolution

- Cooling system integration: Implement active cooling when cell voltages indicate thermal runaway risk (≥4.25V at high temps)

Low-Temperature Operation and Voltage Considerations

Below 0°C, lithium plating becomes a major concern, requiring these protocols:

- Pre-heating to 10°C minimum before charging (measured at cell terminals, not ambient)

- Pulse charging technique: 5-second charge pulses at 0.1C with 30-second rests to allow ion redistribution

- Voltage recovery monitoring: After load removal, healthy cells should rebound ≥50% within 2 minutes at -20°C

High-Power vs. High-Energy Cell Voltage Profiles

| Parameter | High-Power Cells | High-Energy Cells |

|---|---|---|

| Optimal Voltage Window | 3.2V-4.0V (80% utilization) | 3.0V-4.2V (100% utilization) |

| Voltage Sag Under Load | ≤5% at 10C rate | ≤15% at 1C rate |

| End-of-Life Voltage Shift | ±0.05V from new | ±0.15V from new |

Voltage Management in Second-Life Applications

When repurposing used batteries, implement these voltage-based grading steps:

- 72-hour voltage stability test: Cells losing >0.5% voltage/day should be rejected

- Dynamic impedance mapping: Measure voltage response to 1kHz AC signals to detect internal shorts

- Cluster matching: Group cells within 25mV resting voltage and 5% capacity variance

Expert Insight: For aerospace applications, implement triple-redundant voltage monitoring with voting logic – if any two sensors disagree by >15mV, the system automatically initiates safe shutdown procedures.

System-Level Voltage Optimization and Risk Management

Comprehensive Voltage Monitoring Architectures

Modern battery systems require multi-layered voltage monitoring approaches:

| Monitoring Level | Resolution | Update Rate | Critical Applications |

|---|---|---|---|

| Cell-Level | ±1mV | 10Hz | Precision balancing, early fault detection |

| Module-Level | ±5mV | 1Hz | System health monitoring |

| Pack-Level | ±50mV | 0.1Hz | Safety interlocks, user displays |

Advanced Voltage-Based Predictive Maintenance

Implement these voltage analysis techniques for proactive maintenance:

- dV/dQ analysis: Track voltage changes per unit capacity (should remain within 2% variation cycle-to-cycle)

- Resting voltage decay rate: Healthy cells lose <0.5mV/hour after full charge (≥1mV/hour indicates electrolyte breakdown)

- Load response profiling: Compare voltage drop at standardized loads (5% increase suggests contact degradation)

Voltage Threshold Optimization Matrix

Tailor voltage limits based on application priorities:

- Maximum lifespan: 3.65V-3.85V operating window (50% narrower than standard)

- Emergency power: 3.0V-4.3V extended range (with reduced cycle life)

- Cold environments: 3.2V-4.0V restricted range to prevent lithium plating

Quality Assurance Protocols

Implement these voltage validation procedures during manufacturing:

- 72-hour formation cycling: Three complete charge/discharge cycles with <2mV cell-to-cell variation

- Thermal voltage testing: Verify voltage stability across -40°C to +85°C temperature range

- HALT testing: Subject batteries to 150% rated voltage for 24 hours to verify protection circuits

Final Recommendation: For mission-critical systems, implement a dual-range voltage monitoring system with primary (high-accuracy) and secondary (fail-safe) measurement paths, automatically cross-validating every 10ms and initiating shutdown if discrepancies exceed 25mV.

Conclusion: Mastering Li-Ion Voltage for Optimal Performance

Throughout this comprehensive guide, we’ve explored how voltage serves as the critical health indicator for Li-ion batteries—from basic measurement techniques to advanced system-level monitoring. You’ve learned about optimal voltage ranges, temperature compensation, balancing strategies, and specialized applications.

Most importantly, we’ve demonstrated how proper voltage management can double or triple battery lifespan while preventing catastrophic failures. Whether you’re maintaining an EV battery pack or optimizing smartphone performance, these voltage principles apply universally.

Take action today: Implement just one voltage optimization technique—like the 80% charging rule or regular calibration—to immediately extend your battery’s service life. For mission-critical systems, consider investing in professional-grade monitoring equipment. Remember, in battery management, voltage isn’t just a number—it’s the key to unlocking maximum performance, safety, and longevity.

Frequently Asked Questions About Li-Ion Battery Voltage

What is the ideal voltage range for a 3.7V Li-ion battery?

A standard 3.7V nominal Li-ion battery should operate between 2.5V (fully discharged) and 4.2V (fully charged). The sweet spot for longevity is 3.6V-4.0V – staying within this range can double cycle life. For example, electric vehicles typically charge to only 4.1V per cell to extend battery lifespan while maintaining 90% capacity.

How can I accurately measure my battery’s voltage?

Use a digital multimeter with 0.01V resolution (like the Fluke 117) and follow these steps: 1) Let the battery rest for 1 hour after charging/discharging, 2) Set meter to DC voltage mode, 3) Connect red probe to positive terminal, black to negative, 4) Record multiple measurements. Avoid cheap analog meters which often have ±5% inaccuracy.

Why does my battery voltage drop quickly under load?

This voltage sag indicates either high internal resistance (common in aged batteries) or excessive current draw. A healthy 18650 cell should drop less than 0.3V when powering a 5A load. If you see >0.5V drop at moderate loads, the battery likely needs replacement. This is particularly noticeable in power tools during heavy use.

Is it safe to use a battery that fell below 2.5V?

Brief excursions to 2.0-2.5V may be recoverable with slow charging at 0.05C using a lab power supply, but permanent capacity loss of 20-50% is likely. Below 2.0V, copper shunting occurs – these batteries should be recycled immediately due to fire risk. Always check for swelling or heat before attempting recovery.

How does temperature affect voltage readings?

Voltage decreases by about 0.003V/°C when cold and increases when hot. A battery showing 3.7V at 25°C will read ~3.64V at 15°C. More critically, charging below 0°C can cause permanent lithium plating – always warm batteries to at least 10°C before charging in cold environments.

What’s the difference between cell voltage and pack voltage?

Pack voltage is the sum of all series-connected cells. A 3S (3-cell) pack at 4.0V per cell shows 12.0V total. However, individual cells may vary – a “12V” pack could have cells at 4.1V, 3.9V, and 4.0V (still 12V total but unbalanced). Always monitor individual cell voltages in packs for safety.

How often should I calibrate my battery monitoring system?

Professional systems need quarterly calibration using precision voltage references. For consumer devices, perform a full discharge/charge cycle every 3 months to maintain accurate fuel gauges. Note that smartphone battery percentage indicators often become inaccurate after 50-100 cycles without calibration.

Can I mix batteries with different voltage levels?

Absolutely not. Connecting batteries with >0.1V difference causes dangerous current flows between cells. Before paralleling batteries, individually charge them to within 0.05V of each other. In series configurations, always use a BMS to prevent reverse charging of weaker cells, which can lead to thermal runaway.