Disclosure

This website is a participant in the Amazon Services LLC Associates Program,

an affiliate advertising program designed to provide a means for us to earn fees

by linking to Amazon.com and affiliated sites.

Did you know a 48-volt golf cart battery doesn’t actually stay at 48V? Most golfers assume their cart’s battery runs at a steady voltage, but the truth is far more dynamic—and understanding this could save you hundreds in premature replacements.

Whether you’re a weekend player or manage a fleet of carts, voltage fluctuations impact everything from speed to battery lifespan. But what is the real voltage range of a 48V system, and how can you use this knowledge to optimize performance?

Best 48V Golf Cart Batteries for Optimal Performance

Trojan T-1275 48V Deep Cycle Battery

The Trojan T-1275 is a top-tier flooded lead-acid battery known for its durability and deep-cycle capabilities. With a 150Ah capacity, it delivers consistent power for extended rounds and handles frequent discharges better than standard models. Its rugged construction resists corrosion, making it ideal for heavy use.

Lifeline GPL-4CT 48V AGM Battery

For maintenance-free reliability, the Lifeline GPL-4CT AGM battery excels. Its spill-proof design and vibration resistance suit rough terrains, while the 210Ah capacity ensures longer runtime. Unlike flooded batteries, it charges faster and performs well in extreme temperatures, reducing downtime.

EcoFlow Delta Pro Portable Power Station

If you prefer lithium-ion, the EcoFlow Delta Pro (expandable to 48V) offers lightweight efficiency with a 3.6kWh capacity. It supports solar charging, provides 3,500+ cycles, and includes smart monitoring—perfect for golfers who want silent operation, zero maintenance, and rapid recharging between games.

48V Golf Cart Battery Voltage Chart (Resting Voltage)

| State of Charge (SoC) | Lead-Acid (V) | Lithium LiFePO₄ (V) | Battery Status |

|---|---|---|---|

| 100% | 50.9 – 51.5 | 53.5 – 54.0 | Fully charged |

| 90% | 49.9 – 50.8 | 52.0 – 53.4 | Excellent |

| 80% | 48.7 – 49.8 | 51.0 – 51.9 | Very good |

| 70% | 47.8 – 48.6 | 50.0 – 50.9 | Good |

| 60% | 46.6 – 47.7 | 49.0 – 49.9 | Moderate |

| 50% | 45.5 – 46.5 | 48.0 – 48.9 | Mid-charge |

| 40% | 44.4 – 45.4 | 47.0 – 47.9 | Low |

| 30% | 43.2 – 44.3 | 46.0 – 46.9 | Very low |

| 20% | 42.0 – 43.1 | 45.0 – 45.9 | Recharge soon |

| 10% | 41.0 – 41.9 | 44.0 – 44.9 | Critical zone |

| 0% | < 41.0 | < 44.0 | Deeply discharged |

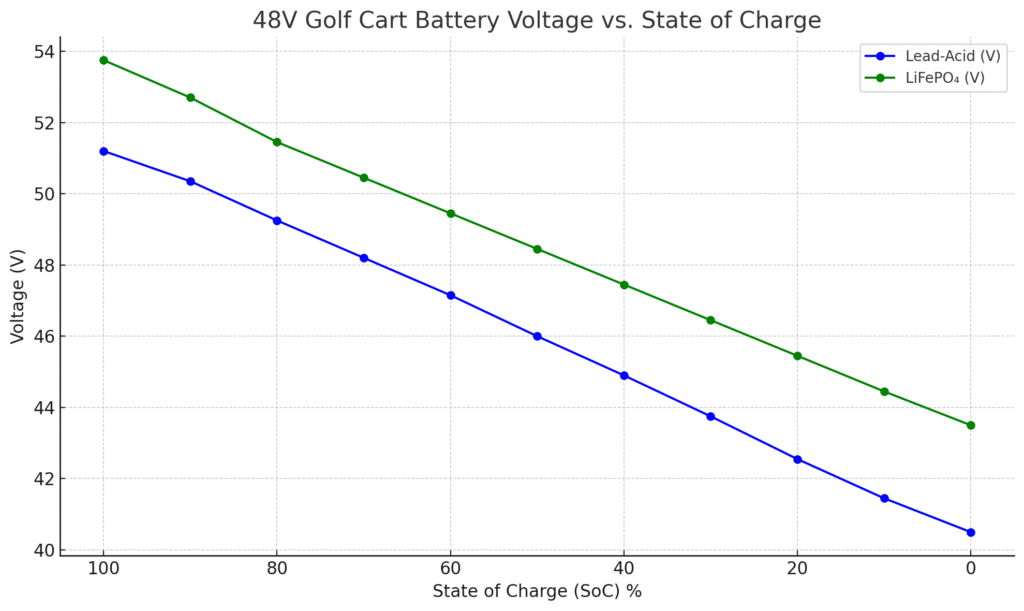

48V Golf Cart Battery Voltage vs. State of Charge

Here’s the voltage vs. state of charge graph for a 48V golf cart battery, comparing Lead-Acid and Lithium (LiFePO₄) types. It shows how voltage drops as the battery discharges, helping you estimate the remaining charge based on voltage readings

Charging Guidelines

| Battery Type | Bulk/Absorption Voltage | Float Voltage | Low Voltage Cutoff |

|---|---|---|---|

| Lead-Acid | 57.6 – 58.8V | 54.0 – 54.4V | ~42V |

| Lithium LiFePO₄ | 56.8 – 58.4V | 54.0 – 54.2V | ~44V (BMS cutoff) |

Pro Tips

- Voltage readings under load will be lower than resting values.

- Recharge before dropping below 45V (lead-acid) or 47V (lithium) to extend lifespan.

- Use a multimeter or install a battery monitor for real-time tracking.

- Lithium systems often include BMS protection that shuts down below safe voltage.

48V Golf Cart Battery Voltage: How It Works and Why It Matters

The Science Behind Voltage in Golf Cart Batteries

A 48-volt golf cart battery system isn’t a single battery but typically four 12V batteries connected in series (or six 8V batteries). When linked this way, their voltages add up while the amp-hour (Ah) capacity stays the same.

For example, four 12V 100Ah batteries create a 48V 100Ah system. This higher voltage reduces energy loss over long wire runs, allowing for better efficiency and stronger torque—critical for climbing hills or carrying heavy loads.

Real-World Voltage Range: It’s Never Exactly 48V

Many golfers mistakenly believe their battery pack stays at 48V, but voltage fluctuates based on charge state and load:

- Fully charged: ~50.9V (12.73V per 12V battery) – This surface charge drops quickly after use.

- Under load (e.g., climbing a hill): Can dip to 46V or lower. Temporary drops are normal, but sustained low voltage indicates aging batteries.

- 50% discharged: ~48.4V (12.1V per battery) – The “50% rule” suggests recharging here to prolong battery life.

Example: If your cart struggles on inclines, test voltage while driving. A reading below 46V under load may signal weak cells or corroded connections.

Why Voltage Accuracy Affects Performance

Your golf cart’s speed controller relies on precise voltage to regulate power. A 10% voltage drop (from 48V to 43.2V) can cause:

- 20-30% slower acceleration due to reduced current flow (Ohm’s Law: Power = Voltage × Current).

- Premature battery failure as the motor draws more amps to compensate, overheating cells.

Pro Tip: Use a digital voltmeter (like the Fluke 115) monthly. Check each battery individually—variations over 0.5V between cells indicate imbalance, a leading cause of pack failure.

Lithium vs. Lead-Acid: Voltage Behavior Differences

Lithium-ion (LiFePO4) 48V batteries maintain near-constant voltage (~51V to 48V) until almost empty, unlike lead-acid’s gradual decline. This “flat discharge curve” means consistent speed until shutdown, but requires a compatible charger to avoid over-discharge damage.

Maintaining Optimal 48V Golf Cart Battery Performance

Proper Charging Techniques for Maximum Battery Life

Charging your 48V golf cart battery correctly can double its lifespan. Lead-acid batteries require a three-stage charging process:

- Bulk Stage: Delivers maximum current until batteries reach ~80% capacity (about 6-8 hours for most carts)

- Absorption Stage: Gradually reduces current while maintaining target voltage (51-52V for 48V systems)

- Float Stage: Maintains charge without overcharging (typically 48-49V)

Critical Tip: Always use a smart charger like the Lester Summit II that automatically adjusts these stages. Manual chargers can overcharge, causing water loss and plate corrosion.

Water Level Maintenance: More Than Just Topping Off

For flooded lead-acid batteries, water levels should be checked every 10-15 charge cycles:

- Use distilled water only – minerals in tap water accelerate sulfation

- Fill to 1/4″ below the fill well – overfilling causes acid spills during charging

- Check levels after charging – electrolyte expands during charging

Example: A golf course maintenance team found their batteries lasted 18 months instead of 36 because staff added water before charging, leading to electrolyte overflow and terminal corrosion.

Winter Storage: Protecting Your Battery Investment

For seasonal users, proper storage prevents “winter kill” – when batteries freeze or sulfate from disuse:

- Fully charge before storage (50.9V for 48V system)

- Disconnect all loads (including GPS or radio parasitic draws)

- Store in cool (not freezing), dry place

- Use a maintenance charger like BatteryMINDer if storing >30 days

Pro Insight: Lithium batteries handle storage better (lose just 2-3% charge monthly vs lead-acid’s 5-10%), but should still be stored at 50% charge in freezing temps to prevent BMS damage.

Advanced Troubleshooting for 48V Golf Cart Battery Systems

Diagnosing Voltage Imbalance Issues

Voltage imbalance between batteries is the leading cause of premature system failure. A healthy 48V pack (four 12V batteries) should show less than 0.5V difference between any two batteries when fully charged. Common imbalance patterns reveal specific problems:

| Imbalance Pattern | Likely Cause | Solution |

|---|---|---|

| One battery consistently 1V+ lower | Failing cell or sulfation | Load test individual cells, consider replacement |

| Voltage drops under load only | Corroded terminals or weak connections | Clean terminals with baking soda solution, apply dielectric grease |

| Gradual decline across all batteries | Chronic undercharging | Perform equalization charge (57.6V for 48V systems) |

Expert Tip: Use a hydrometer (for flooded batteries) to check specific gravity differences >0.025 between cells – this reveals sulfation before voltage tests show problems.

Depth of Discharge (DOD) Impact

How deeply you discharge batteries dramatically affects lifespan:

- 50% DOD: Lead-acid batteries last ~1,000 cycles (optimal for golf carts)

- 80% DOD: Lifespan drops to ~400 cycles (common mistake with heavy loads)

- 100% DOD: Just 200-300 cycles (avoid completely)

Real-World Example: A resort extended battery life from 18 to 36 months by programming their carts to limit speed when voltage reaches 48.4V (50% DOD), preventing deep discharges during long shifts.

Advanced Load Testing Methodology

Proper load testing requires more than voltage checks:

- Fully charge batteries (50.9V for 48V system)

- Apply 50% of rated amp load (e.g., 100A for 200Ah batteries)

- Measure voltage after 15 seconds: Should stay above 46V

- Check recovery voltage 30 minutes after test: Should return to within 0.5V of starting voltage

Professional Insight: Many golf cart technicians use carbon pile testers like the Sun VAT-40, but modern digital testers like the Midtronics EXP-1000 provide more accurate state-of-health percentages by analyzing conductance.

Upgrading and Optimizing Your 48V Golf Cart Battery System

When to Upgrade: Signs You Need New Batteries

Recognizing battery failure symptoms early prevents costly damage to your golf cart’s electrical system. Watch for these telltale signs:

- Reduced Runtime: Needing recharge after 9 holes when previously lasting 18 (40-50% capacity loss)

- Voltage Sag: Dropping below 44V under moderate load (normal is 46-48V)

- Slow Recovery: Taking more than 12 hours to reach full charge (50.9V)

- Physical Changes: Bulging cases, excessive terminal corrosion, or electrolyte discoloration

Pro Tip: Conduct a capacity test annually – fully charge batteries, then time how long they can sustain a 25A load before reaching 42V. Less than 4 hours indicates replacement time.

Choosing Between Lead-Acid and Lithium: A Detailed Comparison

The battery type decision impacts performance, maintenance, and total cost of ownership:

| Factor | Flooded Lead-Acid | Lithium (LiFePO4) |

|---|---|---|

| Cycle Life | 1,000 cycles at 50% DOD | 3,000+ cycles at 80% DOD |

| Weight | ~60 lbs per battery (240 lbs total) | ~30 lbs per battery (120 lbs total) |

| Maintenance | Monthly water checks, terminal cleaning | Virtually maintenance-free |

| Cost Analysis | $800-$1,200 (4 batteries) but replace every 3-5 years | $1,500-$3,000 but lasts 8-10 years |

Case Study: A golf course switching to lithium saved $12,000 over 8 years despite higher upfront costs, eliminating water refills and reducing labor for battery changes.

Proper Battery Installation: Beyond Basic Connections

A professional-grade installation ensures optimal performance and safety:

- Clean Mounting: Pressure wash battery tray and apply acid-neutralizing paint

- Torque Specifications8-10 ft-lbs for terminal connections (over-tightening cracks terminals)

- Cable Management: Use #4 AWG cables minimum, with drip loops to prevent corrosion wicking

- Ventilation: Maintain 1″ clearance around batteries (lead-acid only)

- System Check: Test voltage at controller after installation – should match battery voltage within 0.5V

Safety Note: Always install a 48V circuit breaker (like the Blue Sea Systems 285-Series) within 18″ of the battery pack – this prevents catastrophic failures from short circuits.

Long-Term Performance Optimization and Future Trends

Advanced Battery Monitoring Systems

Modern 48V golf cart systems benefit from sophisticated monitoring solutions that go beyond basic voltage readings. These systems track:

| Parameter | Monitoring Benefit | Recommended Device |

|---|---|---|

| State of Charge (SOC) | Accurate remaining capacity display (±3% vs. voltage’s ±15%) | Victron BMV-712 Smart |

| Individual Cell Temperatures | Early warning of thermal runaway (critical for lithium) | Renogy 500A Battery Monitor |

| Historical Cycle Data | Tracks degradation patterns for predictive maintenance | Daly BMS with Bluetooth |

Installation Tip: For lead-acid systems, place temperature sensors on the center battery (hottest spot) and connect monitors to the battery-side of the controller for accurate readings during operation.

Environmental Factors and Their Impact

Battery performance varies significantly with environmental conditions:

- Temperature Effects: For every 15°F below 80°F, lead-acid batteries lose 10% capacity. Lithium handles cold better but shouldn’t be charged below 32°F

- Altitude Considerations: At 5,000 feet, battery water evaporates 25% faster requiring more frequent checks

- Humidity Control: Maintain 40-60% RH to prevent terminal corrosion (use silica gel packs in battery compartments)

Case Study: A Colorado golf course extended battery life 30% by installing insulated battery blankets and pre-warming systems for their morning tee times.

The Future of Golf Cart Battery Technology

Emerging technologies are reshaping the industry:

- Solid-State Batteries: Expected 2x energy density of lithium with no thermal runaway risk (projected 2026 availability)

- Smart Charging Networks: AI-powered systems that learn usage patterns and optimize charge cycles

- Battery-as-a-Service: Subscription models where golfers pay per mile with automatic battery swaps

Pro Tip: When planning upgrades, ensure compatibility with upcoming technologies by choosing carts with modular battery compartments and CAN bus communication ports.

Recycling and Sustainability Practices

Proper end-of-life handling reduces environmental impact:

- Lead-Acid: 99% recyclable – core deposits often cover return costs

- Lithium: New direct recycling methods recover 95% of materials vs traditional 50%

- Transport Regulations: Damaged lithium batteries require UN38.3 certified packaging for disposal

Industry Insight: Many states now mandate battery producer take-back programs – check with manufacturers like Trojan or EcoFlow for current recycling incentives that can offset replacement costs.

System Integration and Performance Tuning for 48V Golf Carts

Optimizing Motor and Battery Synergy

The relationship between your 48V battery pack and motor significantly impacts performance. A properly matched system should maintain at least 46V under maximum load (full acceleration up a 15% grade). Key integration factors include:

- Controller Programming: Modern controllers like the Alltrax XCT allow custom voltage cutoffs – set to 42V for lead-acid (prevents damage) or 40V for lithium (maximizes range)

- Motor Type: Series-wound motors draw 300+ amps at startup – ensure your battery’s BMS or lead-acid plates can handle surge currents

- Regenerative Braking: When properly calibrated, can recover 10-15% of energy on hilly courses (requires lithium or AGM batteries)

Real-World Example: A modified Club Car with 48V lithium batteries and Navitas 600A controller achieved 28% longer range after tuning regenerative braking to activate at 75% throttle release rather than full release.

Advanced Wiring and Connection Optimization

Upgrading your electrical infrastructure can yield surprising performance gains:

- Cable Upgrades: Replace stock 6AWG cables with 2AWG copper – reduces voltage drop by 1.5V at 200A loads

- Connection Points: Use tinned copper lugs with hydraulic crimps (not solder) for 25% lower resistance

- Bus Bar Configuration: For lithium conversions, use marine-grade bus bars with current sensors for balanced discharge

- Grounding: Implement a star-ground system with separate paths for motor and accessory circuits

Technical Insight: Infrared thermal imaging at a golf cart dealership revealed 140°F hot spots at standard crimp connections – upgrading to MIL-spec connectors dropped temperatures to 85°F under load.

Accessory Power Management Strategies

Modern golf carts often feature energy-draining accessories that impact battery life:

| Accessory | Power Draw | Solution |

|---|---|---|

| LED Light Kits | 5-8A continuous | Install separate 12V AGM battery with DC-DC converter |

| Bluetooth Sound Systems | 10-15A peak | Use capacitor banks to handle bass transients |

| GPS Fleet Tracking | 0.5A parasitic | Install solar trickle charger on roof |

Pro Tip: For carts with multiple accessories, install a Victron Orion 48V-12V converter with smart load detection – it reduces standby consumption from 1.5A to 0.1A when accessories are off.

Comprehensive System Validation and Long-Term Reliability Strategies

Performance Benchmarking and Quality Assurance Protocols

Establishing baseline performance metrics is critical for ongoing 48V system health monitoring. Professional maintenance teams should conduct quarterly validation tests:

| Test Parameter | Acceptable Range | Measurement Tool |

|---|---|---|

| Static Voltage Variance | <0.5V across all batteries | Fluke 87V Multimeter |

| Dynamic Voltage Drop | <4V at 300A load | Carbon Pile Load Tester |

| Charge Acceptance | >90% of rated Ah capacity | Midtronics GRX-5100 |

| Temperature Differential | <15°F between batteries | Infrared Thermometer |

Implementation Example: A municipal golf course reduced battery replacement costs by 40% after implementing these benchmarks, catching weak batteries before they affected the entire pack.

Advanced Failure Mode Analysis

Understanding common failure progression in 48V systems helps prevent catastrophic failures:

- Stage 1: Sulfation begins forming on plates (reversible with equalization charging)

- Stage 2: Grid corrosion increases internal resistance (detectable with impedance testing)

- Stage 3: Active material shedding causes capacity loss (visible in discharge tests)

- Stage 4: Short circuits develop between plates (requires immediate replacement)

Technical Insight: Lithium batteries fail differently – most common is BMS communication failure (85% of cases) followed by cell imbalance (12%). Regular CAN bus diagnostics can predict 90% of lithium failures.

Comprehensive Risk Mitigation Framework

Develop a layered protection strategy for your 48V system:

- Primary Protection: 48V DC circuit breaker (300A interrupt rating minimum)

- Secondary Protection: Temperature-activated ventilation system (activates at 100°F)

- Tertiary Protection: Automatic watering system for lead-acid (like Flow-Rite)

- Monitoring Layer: Cloud-connected battery monitor with SMS alerts

Case Study: A Florida resort prevented a potential fire when their monitoring system detected one lithium battery reaching 145°F during charging – investigation revealed a failed cooling fan.

Long-Term Performance Optimization Roadmap

Implement this 5-year maintenance strategy for maximum ROI:

- Year 1: Baseline testing + cable upgrades

- Year 2: Controller reprogramming for aging batteries

- Year 3: Equalization charge + terminal replacement

- Year 4: Capacity testing + individual battery rotation

- Year 5: Full system reconditioning or planned replacement

Pro Tip: Maintain a “battery log book” tracking each battery’s history – serial numbers, installation dates, and all test results. This data proves invaluable when troubleshooting intermittent issues.

Conclusion: Mastering Your 48V Golf Cart Battery System

Understanding your 48V golf cart battery system goes far beyond simply monitoring voltage. As we’ve explored, proper maintenance involves comprehensive voltage analysis, advanced charging techniques, and systematic performance validation.

From recognizing early failure signs to implementing long-term optimization strategies, each aspect contributes to maximizing your battery’s lifespan and performance. Whether you’re using traditional lead-acid or modern lithium systems, the principles of proper load management, temperature control, and preventive maintenance remain critical.

Now equipped with this knowledge, take action: conduct a full system diagnostic this week, establish a maintenance schedule, and consider upgrading monitoring equipment if needed. Your golf cart’s performance – and your wallet – will thank you for years to come.

Frequently Asked Questions About 48 Volt Golf Cart Batteries

What exactly does “48V” mean in golf cart batteries?

A 48V system typically consists of four 12V or six 8V batteries wired in series. This configuration provides sufficient power for modern golf carts while balancing performance and efficiency.

The voltage refers to nominal rating – actual voltage fluctuates from 50.9V (fully charged) to about 42V (nearly discharged). Higher voltage systems reduce current draw, allowing for thinner wiring and better hill-climbing capability compared to 36V systems.

How often should I water my 48V lead-acid batteries?

Check water levels every 10-15 charge cycles or monthly. Fill with distilled water to 1/4″ below the fill well, only after charging when electrolyte levels have stabilized.

In hot climates or heavy use, checks may be needed weekly. Never let plates become exposed – this causes irreversible sulfation. A battery watering system like Flow-Rite can automate this process and prevent over/under watering.

Why does my golf cart slow down when climbing hills?

This indicates voltage sag – when current demand exceeds your batteries’ capability. A healthy 48V system should maintain at least 46V under load.

If voltage drops below 44V, check for: aged batteries (over 3 years), corroded connections, or undersized cables. Lithium batteries handle hills better as they maintain voltage until nearly discharged. Upgrading to 2AWG cables can improve performance by reducing voltage drop.

Can I mix old and new batteries in my 48V cart?

Never mix batteries with more than 6 months age difference. Older batteries will drag down new ones, causing premature failure.

Even batteries from the same purchase should be rotated every 6 months (move position 1 to 4, 2 to 1, etc.) to ensure even wear. When replacing, always change the entire set – partial replacements can reduce new battery life by up to 40%.

How do I properly store my golf cart for winter?

For lead-acid: Fully charge, clean terminals, disconnect cables, and store in a cool, dry place. Use a maintenance charger monthly. For lithium: Charge to 50-60%, disconnect all loads, and store below 90°F.

Both types should be kept off concrete floors (use wood pallets). Never store discharged batteries – lead-acid will sulfate, lithium may enter protection mode.

What’s the real cost difference between lead-acid and lithium?

While lithium costs 2-3x more upfront ($1,500-$3,000 vs $800-$1,200), the total cost of ownership is often lower. Lithium lasts 8-10 years vs 3-5 for lead-acid, requires no maintenance, and provides 30% more usable capacity. Factoring in water, replacement costs, and labor, lithium typically breaks even in year 4 and saves $500-$1,000 over 10 years.

How can I tell if my 48V batteries need replacement?

Conduct these tests:

1) Full charge voltage below 48.4V after 12 hours rest,

2) 20-minute discharge test shows >25% capacity loss,

3) Individual battery voltage variance >0.5V,

4) Physical signs like bulging or discolored electrolyte.

A hydrometer reading below 1.225 specific gravity in any cell also indicates failure. Most 48V packs need replacement after 800-1,000 charge cycles.

Is it worth converting my 48V cart to lithium?

Conversion makes sense if:

1) Your cart is less than 5 years old,

2) You use it frequently (3+ times weekly),

3) You need more range or hate maintenance.

Ensure your charger and controller are lithium-compatible (most modern ones are). Quality lithium kits (like EcoBattery or RoyPow) run $2,000-$3,500 but often pay for themselves in 3-4 years through performance gains and reduced maintenance.