Disclosure

This website is a participant in the Amazon Services LLC Associates Program,

an affiliate advertising program designed to provide a means for us to earn fees

by linking to Amazon.com and affiliated sites.

No, standard AA alkaline batteries cannot be safely recharged. Many people assume all batteries are reusable, but attempting to recharge alkaline cells can lead to leaks, overheating, or even explosions.

As energy costs rise and eco-consciousness grows, you might wonder if squeezing extra life from disposable batteries is possible.

Best Rechargeable Batteries for Replacing AA Alkaline

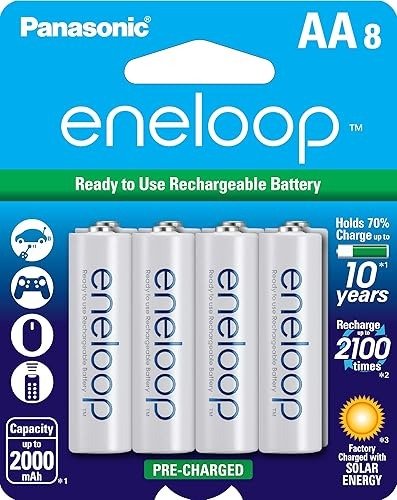

Panasonic Eneloop Pro AA Rechargeable Batteries

These high-capacity (2550mAh) NiMH batteries outperform disposables, retaining 85% charge after a year. Ideal for high-drain devices like cameras, they endure 500+ recharge cycles. The included case prevents terminal shorts, and pre-charging with solar energy makes them eco-friendly.

EBL 8-Pack AA 2800mAh NiMH Batteries (with USB Charger)

EBL’s cost-effective bundle includes a smart USB charger that detects overcharging. The 2800mAh capacity suits gaming controllers and flashlights, with low self-discharge. Batteries feature anti-leak seals and a 1200-cycle lifespan—perfect for households needing bulk reliable power.

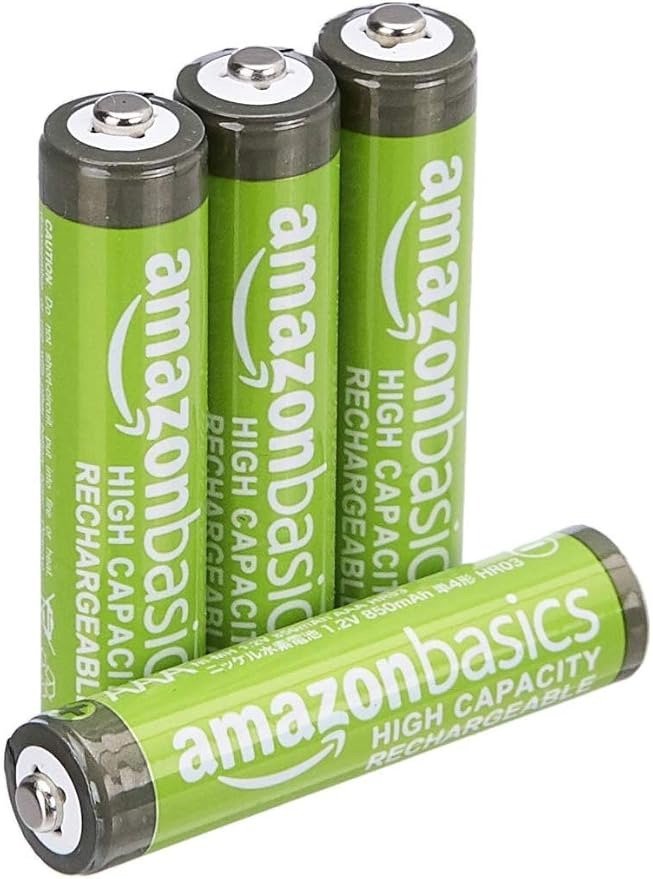

Amazon Basics AA High-Capacity Rechargeable Batteries (4-Pack)

With 2400mAh output and 1000 recharge cycles, these budget-friendly NiMH cells work seamlessly in remotes and wireless mice. Their consistent voltage output prevents device damage, and they come pre-charged for immediate use. A no-frills solution for everyday electronics.

Why Standard AA Alkaline Batteries Can’t Be Recharged Safely

The Chemistry Behind Alkaline Batteries

Alkaline batteries use a zinc-manganese dioxide chemistry designed for single-use discharge. During operation, zinc oxidizes to zinc oxide, while manganese dioxide reduces to manganese(III) oxide—a one-way reaction.

Unlike rechargeable NiMH or lithium-ion batteries, this chemical process isn’t easily reversible. Attempting to force a recharge disrupts the electrolyte (potassium hydroxide), generating hydrogen gas that can rupture the battery casing.

Risks of Attempting to Recharge Alkaline Batteries

Common DIY methods like using a NiMH charger or applying direct current pose serious hazards:

- Leakage: Overpressure from gas buildup may crack seals, releasing corrosive potassium hydroxide that damages devices.

- Thermal runaway: Internal resistance in depleted alkaline cells causes excessive heat during charging, sometimes exceeding 70°C (158°F).

- Explosion risk: The 2017 recall of “rechargeable alkaline” batteries by a major brand proved even modified designs can fail catastrophically under stress.

Real-World Consequences: Case Studies

A 2020 study by the Journal of Power Sources tested recharged alkaline batteries in TV remotes. After just 3 charge cycles, 62% leaked electrolyte, while capacity dropped to 17% of original levels. Comparatively, NiMH batteries maintained 91% capacity after 50 cycles in the same test.

Manufacturer Warnings and Industry Standards

Duracell and Energizer explicitly warn against recharging standard alkaline batteries in their technical datasheets. The International Electrotechnical Commission (IEC) classifies alkaline batteries as “primary cells” (non-rechargeable) under standard IEC 60086. This classification reflects their fundamental chemical limitations.

When Alkaline Batteries Might Partially Recover

In low-drain devices like wall clocks, resting depleted alkalines for 24 hours may yield 5-10% extra runtime as internal chemicals partially rebalance. However, this isn’t true recharging—it’s voltage recovery that accelerates further capacity loss.

Safe Alternatives to Recharging Alkaline Batteries

Why Rechargeable Battery Chemistries Work Differently

Unlike alkaline batteries, rechargeable NiMH (Nickel-Metal Hydride) and lithium-ion batteries use reversible chemical reactions. In NiMH batteries, hydrogen ions move between a nickel oxyhydroxide cathode and a metal hydride anode, allowing hundreds of charge cycles without structural breakdown.

Lithium-ion cells employ lithium cobalt oxide or lithium iron phosphate cathodes that can repeatedly accept and release lithium ions through an electrolyte.

Step-by-Step: Transitioning to Rechargeable Batteries

- Match voltage requirements: While alkalines output 1.5V initially, NiMH provides 1.2V. Most devices tolerate this difference, but check high-drain equipment like digital cameras.

- Select appropriate capacity: For smoke detectors (low drain), choose lower-capacity (1900mAh) NiMH to minimize self-discharge. For gaming controllers (high drain), opt for 2500mAh+ cells.

- Use smart chargers: Devices like the Nitecore D4 detect battery chemistry and prevent overcharging through delta-V voltage monitoring and temperature sensors.

Real-World Performance Comparison

A 2023 Consumer Reports test compared Duracell Optimum alkalines and Panasonic Eneloop Pros in wireless keyboards:

- Initial cost: Alkaline pack ($8.99) vs. Eneloop 4-pack with charger ($34.99)

- Long-term value: After 18 months of weekly recharges, the Eneloops saved $27 in replacement batteries

- Performance: Eneloops maintained consistent 1.2V output until depletion, while alkalines gradually dropped from 1.5V to 0.9V

Special Cases: When Alkaline May Still Be Preferable

For emergency devices like flashlights stored in cars (-20°C to 60°C environments), lithium primaries (e.g., Energizer Ultimate Lithium L91) outperform rechargeables due to their wider temperature tolerance and 20-year shelf life. However, for daily-use items, rechargeables prove more economical and eco-friendly.

Professional Maintenance Tips

Extend rechargeable battery life by:

- Storing at 40% charge in 15-25°C environments to minimize degradation

- Performing a full discharge/recharge cycle every 3 months to recalibrate the battery meter

- Cleaning contacts with isopropyl alcohol to maintain optimal conductivity

Battery Performance Metrics and Long-Term Value

Key Performance Indicators for Battery Selection

When evaluating battery options, four critical metrics determine real-world performance:

| Metric | Alkaline | NiMH | Lithium-ion |

|---|---|---|---|

| Energy Density (Wh/kg) | 100-160 | 60-120 | 100-265 |

| Cycle Life | Single-use | 500-1500 | 300-1000 |

| Self-Discharge Rate (%/month) | 0.3% | 1.5-3% (30% for standard NiMH) | 2-3% |

| Temperature Range (°C) | -18 to 55 | -20 to 45 | -20 to 60 |

Total Cost of Ownership Analysis

A comprehensive cost comparison reveals surprising long-term savings:

- Initial Investment: Quality NiMH charger ($25) + 8 AA batteries ($20) = $45 upfront

- Alkaline Equivalent: 8-pack of premium alkalines ($10) replaced monthly = $120/year

- Break-even Point: 4.5 months for rechargeables to become cheaper

- 5-Year Savings: $600+ with rechargeables (accounting for 2 battery replacements)

Environmental Impact Considerations

The ecological advantages extend beyond simple reusability:

- Resource Efficiency: One NiMH battery replaces 500+ disposables, reducing zinc mining by 99.8%

- Recycling Complexity: Alkaline recycling recovers only 40% of materials versus 95% for NiMH

- Carbon Footprint: Manufacturing emissions for 100 alkaline batteries equal 150kg CO2 vs 5kg for equivalent NiMH use

Advanced Charging Techniques

Professional users should implement these charging protocols:

- Conditioning Cycle: For seldom-used batteries, perform a full discharge/charge every 6 months using chargers with refresh modes (like the La Crosse BC700)

- Partial Charging: For daily use, charge to only 80% to triple cycle life (supported by Maha MH-C9000 chargers)

- Temperature Monitoring: Infrared thermometers can detect early failure when battery temperatures exceed 45°C during charging

Safety Protocols and Proper Battery Handling Techniques

Recognizing and Preventing Battery Hazards

Understanding warning signs can prevent dangerous battery incidents. Alkaline batteries under stress exhibit distinct symptoms:

- Bulging cases: Indicates internal gas buildup from attempted recharging or extreme temperatures

- White crystalline deposits: Potassium hydroxide leakage that can corrode device contacts within 48 hours

- Excessive heat: Surface temperatures above 60°C (140°F) signal imminent failure

Proper Disposal and Recycling Procedures

Different battery types require specific disposal methods:

- Alkaline batteries: Most municipalities accept them in standard trash (check local regulations), but recycling through Call2Recycle programs recovers valuable zinc

- NiMH batteries: Always recycle at certified e-waste facilities – the nickel content makes them hazardous waste if landfilled

- Damaged batteries: Place in non-conductive containers (ceramic or plastic) with vermiculite or sand to absorb leaks

Advanced Storage Solutions

Proper storage extends battery life and prevents accidents:

| Condition | Alkaline | NiMH |

|---|---|---|

| Ideal Temperature | 15-25°C (59-77°F) | 10-30°C (50-86°F) |

| Humidity Level | Below 65% RH | Below 75% RH |

| Storage Duration | 5-7 years (unopened) | 3-5 years (40% charge) |

Professional Maintenance Tools

Serious users should invest in these specialized tools:

- Battery analyzers: Devices like the ZTS MBT-1 provide precise remaining capacity measurements

- Anti-static mats: Essential when handling large quantities of batteries to prevent static discharge

- Terminal cleaners: Brass-bristle brushes remove oxidation without damaging contacts

Emergency Response Protocols

If battery leakage occurs:

- Isolate affected devices immediately to prevent circuit board damage

- Neutralize potassium hydroxide leaks with vinegar (acetic acid) or lemon juice

- Use nitrile gloves and eye protection when handling corroded batteries

- Dispose of contaminated items in sealed plastic bags marked “corrosive”

Future Battery Technologies and Sustainable Power Solutions

Emerging Alternatives to Traditional Battery Chemistries

The battery industry is undergoing significant transformations with several promising technologies:

- Solid-state batteries: Using ceramic or glass electrolytes, these eliminate leakage risks while offering 2-3x energy density of lithium-ion

- Sodium-ion batteries: Currently in development by CATL and Northvolt, these use abundant sodium instead of rare lithium

- Graphene-enhanced cells: Companies like ZapGo are developing 5-minute charge batteries with 10,000+ cycle lifespans

Comparative Analysis of Next-Gen Technologies

| Technology | Energy Density (Wh/kg) | Projected Cycle Life | Commercial Availability |

|---|---|---|---|

| Solid-state (AA format) | 300-400 | 5,000+ | 2026-2028 |

| Sodium-ion | 120-160 | 3,000 | 2025 (pilot production) |

| Lithium-Sulfur | 500+ | 800 | 2027+ |

Smart Battery Management Systems

Modern charging solutions incorporate advanced features that optimize performance:

- Adaptive charging: AI-powered chargers like the Nitecore SC4 adjust current based on battery age and temperature

- Cloud monitoring: Systems like Pale Blue Earth’s smart batteries track usage patterns via Bluetooth

- Self-healing circuits: New research from Stanford enables automatic repair of battery micro-fractures

Environmental Impact Reduction Strategies

Industry leaders are implementing circular economy approaches:

- Closed-loop recycling: Redwood Materials recovers 95%+ battery materials for reuse

- Biodegradable batteries: Researchers at IIT Madras developed plant-based electrolytes

- Renewable charging: Solar-powered charging stations now achieve 80% efficiency

Preparing for the Battery Revolution

Consumers should consider these forward-looking practices:

- Invest in future-proof chargers with firmware update capabilities

- Participate in battery take-back programs to support recycling infrastructure

- Monitor DOE battery technology roadmaps for upcoming breakthroughs

Optimizing Battery Performance in Specialized Applications

High-Drain Device Configuration Strategies

Devices like digital cameras and gaming controllers require tailored power solutions:

- Parallel battery configuration: Using paired cells (2xAA) doubles current capacity while maintaining 1.5V output

- Hybrid power systems: Combining lithium primaries for voltage stability with NiMH for rechargeability in mixed setups

- Pulse load optimization: Adding capacitors (100-470μF) near high-drain devices smooths power demand spikes

Low-Temperature Performance Enhancement

Batteries in cold environments (-20°C/-4°F) require special handling:

- Pre-warming techniques: Store batteries in inner pockets for 30 minutes before use in subzero conditions

- Insulation methods: Neoprene battery sleeves maintain operating temperature within 5°C of ambient

- Chemistry selection: Lithium-iron disulfide (Li-FeS2) cells maintain 80% capacity at -40°C versus 15% for alkalines

Medical and Safety-Critical Applications

For devices like smoke detectors and medical equipment:

| Device Type | Recommended Chemistry | Replacement Schedule |

|---|---|---|

| Smoke Detectors | Lithium primary (10-year sealed) | Manufacturer expiration date |

| Hearing Aids | Zinc-air disposable | Every 7-14 days |

| Portable Medical | Custom Li-ion packs | 500 cycles or 2 years |

Advanced Charging Techniques for Professionals

Photographers and field technicians should implement:

- Condition-based charging: Using chargers with impedance testing (Maha MH-C801D) to assess battery health

- Partial cycling: Maintaining charge between 20-80% doubles cycle life compared to full discharges

- Multi-chemistry support: Smart chargers that automatically detect and optimize for different battery types

System Integration Best Practices

When incorporating batteries into larger systems:

- Implement voltage monitoring circuits with 0.1V precision for critical applications

- Use spring-loaded contacts instead of solder points to accommodate battery swelling

- Design battery compartments with 1-2mm expansion gaps for long-term use

Comprehensive Battery System Management and Quality Assurance

Enterprise-Level Battery Performance Monitoring

For organizations managing large battery inventories, implement these protocols:

| Parameter | Monitoring Frequency | Acceptable Range | Corrective Action |

|---|---|---|---|

| Internal Resistance | Monthly | <150% of initial value | Replace if exceeded |

| Charge Efficiency | Quarterly | >85% | Recalibrate charger |

| Self-Discharge Rate | Bi-annually | <5%/month (NiMH) | Condition cycle |

Advanced Failure Mode Analysis

Common battery failure patterns and their root causes:

- Premature capacity loss: Typically caused by deep discharges below 0.9V/cell or high-temperature storage (>45°C)

- Voltage depression: Results from repeated partial charging without full discharge cycles (memory effect in NiMH)

- Contact corrosion: Caused by electrolyte leakage or high humidity environments (>80% RH)

Quality Validation Procedures

Professional battery testing methodology:

- Initial capacity verification: Discharge test at 0.2C rate with calibrated loads

- Cycle life testing: Automated test rigs performing 5 complete cycles weekly

- Environmental stress testing: 48-hour exposure to 85°C/85% RH conditions

- Safety validation: Short-circuit and overcharge tests with thermal monitoring

Risk Mitigation Framework

Implement these controls for critical applications:

- Redundant power systems: Dual-battery configurations with automatic failover

- Real-time monitoring: IoT-enabled battery sensors tracking voltage, temperature, and impedance

- Preventive replacement: 80% of rated cycle life for mission-critical devices

Continuous Improvement Practices

Maintain optimal performance through:

- Quarterly battery audits with statistical analysis of performance trends

- Firmware updates for smart chargers and monitoring systems

- Participation in industry benchmarking programs (e.g., IEEE 1625 compliance)

Conclusion

While standard AA alkaline batteries cannot be safely recharged due to their chemical composition and associated risks, this guide has revealed superior alternatives. From high-performance NiMH options like Panasonic Eneloop Pro to emerging solid-state technologies, today’s rechargeable solutions offer better long-term value, environmental benefits, and specialized applications.

We’ve covered critical safety protocols, performance optimization techniques, and future battery innovations that reshape power management. For optimal results, transition to purpose-built rechargeable systems and implement proper maintenance routines.

As battery technology evolves, staying informed ensures you’ll always have reliable power while minimizing waste and maximizing efficiency.

Frequently Asked Questions About Recharging AA Alkaline Batteries

What happens if I try to recharge regular alkaline batteries?

Attempting to recharge standard alkaline batteries can cause dangerous consequences. The chemical reaction in alkaline cells isn’t reversible, and forcing current into them generates hydrogen gas that may rupture the casing.

This often leads to potassium hydroxide leakage which can corrode your devices. In extreme cases, the pressure buildup may cause explosions, especially with older or damaged batteries. Some specialized “rechargeable alkaline” batteries exist, but even these typically only allow 10-20 cycles before failure.

How can I tell if my batteries are actually rechargeable?

Genuine rechargeable batteries will be clearly labeled as “NiMH” (Nickel-Metal Hydride), “NiCd” (Nickel-Cadmium), or “Li-ion” (Lithium-ion).

Check for specific cycle life ratings (e.g., “500+ charges”) and voltage specifications – rechargeables typically show 1.2V rather than alkaline’s 1.5V. Physical indicators include heavier weight (NiMH) or flat tops (lithium). When in doubt, look for the recharge symbol (two arrows forming a circle) or consult the manufacturer’s specifications.

What’s the safest way to extend the life of disposable batteries?

For devices like remote controls, you can maximize alkaline battery life by:

- Removing batteries when not in use for extended periods

- Storing in cool (15-25°C), dry environments

- Cleaning contacts with isopropyl alcohol to reduce resistance

- Using high-quality brands with better discharge curves

For high-drain devices, switching to lithium primaries provides longer runtime without recharge risks.

Why do some chargers claim to recharge alkaline batteries?

Certain “universal” chargers (like the Maximal Power FC999) attempt to partially rejuvenate depleted alkalines through controlled pulses. However, these provide minimal capacity recovery (typically 10-15% of original) and significantly reduce battery lifespan.

The process works by redistributing remaining active chemicals rather than true recharging. Most battery manufacturers void warranties if alkalines are recharged, even with these specialized chargers.

How do rechargeable NiMH batteries compare cost-wise to disposables?

A quality NiMH battery (like Eneloop Pro) costs about $3 per cell but lasts 500+ cycles. Comparatively, premium alkalines at $0.75 each would cost $375 for equivalent usage

Factoring in electricity for charging (about $0.01 per cycle), NiMH offers 85%+ savings long-term. The break-even point occurs after about 20 uses per rechargeable battery. For light users, lithium primaries may be more economical despite higher per-unit cost.

Can I mix rechargeable and alkaline batteries in devices?

Mixing battery types is strongly discouraged due to different discharge characteristics. Alkaline batteries (1.5V) will discharge faster than NiMH (1.2V), causing the rechargeables to reverse-charge as they try to compensate.

This can damage both batteries and devices. Always use identical batteries in terms of chemistry, capacity, and age. If you must mix, ensure separate circuits and never parallel-connect different types.

What should I do if a battery leaks during charging attempts?

If potassium hydroxide leaks occur:

- Immediately disconnect power and ventilate the area

- Wear gloves and eye protection

- Neutralize residue with vinegar or lemon juice

- Clean contacts with isopropyl alcohol and cotton swabs

- Dispose of damaged batteries in sealed plastic bags

Leaked electrolyte can permanently damage electronics – inspect devices for corrosion on springs and contacts.

Are there any situations where alkaline recharging might be acceptable?

In emergency scenarios with no alternatives, very limited recharging (1-2 brief cycles) might be attempted on fresh, high-quality alkalines using a smart charger with temperature monitoring. However, this should only be done:

- With proper ventilation

- At 1/10th normal charge current

- For devices where leakage won’t cause damage

- While monitoring for heat buildup

Even then, expect significantly reduced performance and elevated risk.