Disclosure

This website is a participant in the Amazon Services LLC Associates Program,

an affiliate advertising program designed to provide a means for us to earn fees

by linking to Amazon.com and affiliated sites.

No, you should not charge a lithium battery with a normal charger—doing so risks damage, overheating, or even fire. Many people assume all chargers are interchangeable, but lithium batteries require precise voltage and current control that standard chargers lack.

As lithium batteries power everything from smartphones to electric cars, understanding proper charging methods is critical for safety and performance. You might be tempted to use an old charger in a pinch, but the consequences could be costly. Let’s uncover why lithium batteries demand specialized charging and how to do it right.

Best Chargers for Lithium Batteries

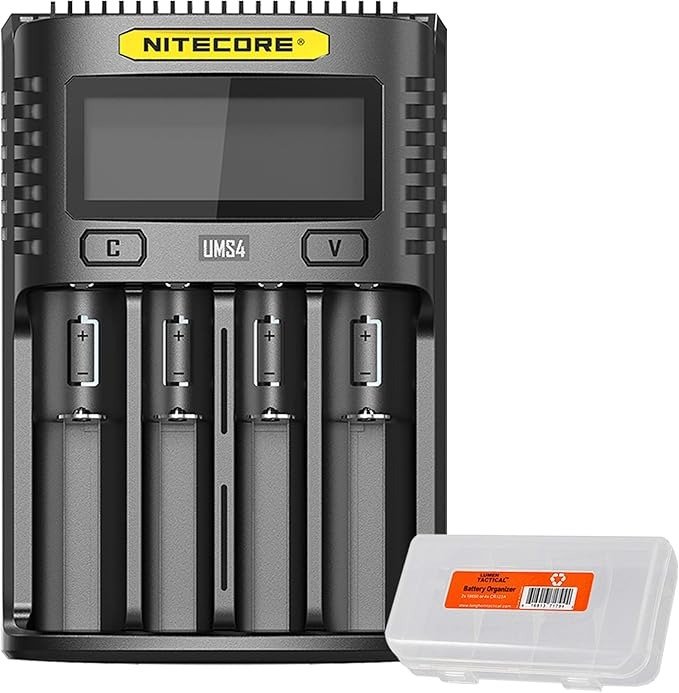

Nitecore UMS4 Smart Charger

This advanced charger supports multiple lithium battery chemistries (Li-ion, LiFePO4) with intelligent voltage detection up to 4.2V. Its 3A fast-charging capability, LCD display, and built-in safety protections (overcharge/overcurrent) make it ideal for power users who need reliability and speed.

XTAR VC8 Charger

With 8 independent charging slots and compatibility with Li-ion/NiMH batteries, the VC8 offers precision charging (0.5A–3A adjustable current). Its voltage display and recovery mode for over-discharged batteries ensure optimal performance, making it perfect for professionals managing multiple devices.

Efest LUSH Q4 Intelligent LED Battery Charger

Designed for high-capacity lithium batteries, the LUSH Q4 delivers 1A×4 or 2A×2 charging modes. Its robust construction, reverse-polarity protection, and compatibility with 26650/18650 cells cater to vapers and flashlight enthusiasts who prioritize safety and versatility.

Why Normal Chargers Are Dangerous for Lithium Batteries

Using a standard charger designed for NiMH or lead-acid batteries on a lithium battery can lead to catastrophic failures. Unlike traditional batteries, lithium-ion cells require precise voltage regulation and current control throughout the charging cycle. A normal charger lacks these critical safeguards, potentially causing:

- Overcharging: Lithium batteries operate within a tight voltage range (typically 3.0V–4.2V per cell). Exceeding this can trigger thermal runaway—a chain reaction where overheating leads to fire or explosion. Example: A lead-acid charger delivering 14V+ can destroy a 3.7V Li-ion cell.

- Incorrect Charging Algorithm: NiMH chargers use “-ΔV” (voltage drop) to detect full charge, while lithium batteries require constant current (CC) followed by constant voltage (CV) charging. Mismatched algorithms result in incomplete or unsafe charging.

- No Cell Balancing: Multi-cell lithium packs (like those in laptops) need balanced charging to prevent voltage disparities. Normal chargers ignore this, risking uneven wear or cell failure.

Real-World Consequences

In 2016, hoverboard fires were traced to cheap chargers overcharging lithium packs. Similarly, repurposing a car battery charger for an e-bike’s 48V Li-ion system can cause permanent capacity loss or swelling due to incorrect voltage thresholds.

Technical Safeguards in Lithium Chargers

Dedicated lithium chargers include:

- Voltage Cutoff: Automatically stops charging at 4.2V±1% to prevent overvoltage.

- Temperature Monitoring: Halts charging if the battery exceeds 45°C (113°F).

- Current Regulation: Adjusts amperage based on the battery’s state (e.g., 1C rate for fast charging).

Practical Tip: If you must use an alternative charger temporarily, verify its output matches your battery’s specs exactly. For example, a 12V LiFePO4 battery (nominal 13.6V) should only pair with a charger set to that voltage—not a generic 12V lead-acid charger.

How to Safely Charge Lithium Batteries Without a Dedicated Charger

While dedicated lithium chargers are ideal, certain situations may require temporary alternatives. Here’s how to mitigate risks when using non-standard charging methods, with detailed precautions and step-by-step guidance.

Step-by-Step: Using a Bench Power Supply

For advanced users, a regulated DC power supply can serve as a temporary solution if configured properly:

- Verify Battery Specifications: Check your lithium battery’s voltage (e.g., 3.7V for 18650 cells) and max charge current (usually 0.5C–1C of capacity). Example: A 2500mAh battery should charge at ≤2.5A.

- Set Voltage Precisely: Adjust the power supply to the battery’s full charge voltage (4.2V for Li-ion, 3.65V for LiFePO4). Never exceed this—even 0.5V over can degrade cells.

- Limit Current: Set the current to 50–70% of the battery’s rated charge current for safety. Use the power supply’s constant current (CC) mode initially.

- Monitor Actively: Disconnect immediately when current drops to 3–5% of the set value (indicating full charge). Never leave unattended.

Alternative: Smart Chargers with Multi-Chemistry Support

Some universal chargers like the Nitecore SC4 (mentioned earlier) offer selectable lithium modes. Key checks:

- Confirm the charger explicitly lists your battery type (e.g., “Li-ion” or “LiFePO4”).

- Verify voltage compatibility—a charger labeled “3.7V” won’t work for 14.8V (4S) packs.

- Prioritize chargers with temperature sensors for added safety.

Critical Warnings

Never use:

- Automatic lead-acid chargers (risk of 14V+ “equalization mode”)

- Unregulated solar panels (voltage spikes can damage BMS circuits)

- USB ports for large lithium packs (limited to 5V/2A, insufficient for most applications)

Real-World Example: A DIY e-bike builder used a lab power supply to charge a 52V pack by manually transitioning from CC to CV mode—but only after triple-checking settings with a multimeter. This highlights the need for constant vigilance with improvised solutions.

Lithium Battery Chemistry and Charging Requirements

To safely charge lithium batteries, you must understand their fundamental electrochemical properties. Unlike other battery types, lithium-ion cells operate through the movement of lithium ions between anode and cathode during charge/discharge cycles.

Key Chemical Properties Affecting Charging

| Chemistry Type | Nominal Voltage | Max Charge Voltage | Temperature Sensitivity |

|---|---|---|---|

| Li-ion (Cobalt Oxide) | 3.7V | 4.2V ±1% | Highly sensitive above 45°C |

| LiFePO4 | 3.2V | 3.65V | More stable up to 60°C |

| NMC (Nickel Manganese Cobalt) | 3.6V | 4.2V | Moderate sensitivity |

The Charging Process Explained

Lithium batteries require a two-stage charging protocol:

- Constant Current (CC) Phase: The charger delivers maximum safe current (typically 0.5C-1C) until reaching ~70% capacity. For a 3000mAh battery, this means 1.5A-3A current.

- Constant Voltage (CV) Phase: The charger maintains exact peak voltage while gradually reducing current. This prevents overcharging while completing the final 30% of capacity.

Critical Safety Mechanisms

All quality lithium chargers incorporate these protection circuits:

- Overvoltage Protection (OVP): Cuts off charging if voltage exceeds specifications by even 0.05V

- Overcurrent Protection (OCP): Prevents excessive current that could cause internal heating

- Temperature Monitoring: Uses NTC thermistors to detect abnormal cell heating

- Cell Balancing: For multi-cell packs, ensures all cells charge evenly

Expert Tip: When testing unknown batteries, always start with conservative 0.2C charging rates (500mA for a 2500mAh cell) and monitor temperature rise with an infrared thermometer. More than 10°C increase during charging indicates potential cell damage.

Advanced Charging Techniques for Different Lithium Battery Applications

Different lithium battery applications require specialized charging approaches to maximize performance and lifespan. Understanding these variations is crucial for safe operation across various devices and scenarios.

Application-Specific Charging Protocols

Each lithium battery application has unique charging requirements:

- Consumer Electronics (Smartphones/Laptops):These devices use sophisticated battery management systems (BMS) that communicate with the charger. For example, USB-PD (Power Delivery) chargers negotiate voltage/current levels with the device. Never bypass the original charging circuitry – doing so can disable critical safety features.

- Electric Vehicles (EVs):EV charging involves complex thermal management systems. The charging rate automatically adjusts based on battery temperature (slower in cold weather). DC fast chargers (50-350kW) use liquid cooling to prevent overheating during high-current charging sessions.

- Energy Storage Systems (ESS):Grid-scale lithium batteries use active balancing systems that continuously equalize cell voltages. These systems often employ trickle charging (0.05C) for final capacity top-up to minimize stress on cells.

Temperature Considerations

Lithium batteries have strict temperature operating ranges:

| Condition | Minimum Temp | Maximum Temp | Recommended Range |

|---|---|---|---|

| Charging | 0°C (32°F) | 45°C (113°F) | 15-30°C (59-86°F) |

| Discharging | -20°C (-4°F) | 60°C (140°F) | -10 to 45°C (14-113°F) |

Professional Maintenance Tips

To maximize battery lifespan:

- Partial Charging: Keeping batteries between 20-80% charge reduces stress. Only charge to 100% when necessary for maximum runtime.

- Storage Preparation: For long-term storage, charge to 40-50% and store at 15°C (59°F). This minimizes calendar aging effects.

- Cycle Counting: Track charge cycles and consider replacement after 500-1000 cycles (depending on chemistry) when capacity drops below 80%.

Expert Insight: Industrial applications often use impedance spectroscopy to assess battery health. While not practical for consumers, noticing increased charge times or reduced runtime can indicate aging batteries needing replacement.

Long-Term Lithium Battery Care and Emerging Charging Technologies

Proper long-term maintenance and awareness of evolving charging technologies can significantly extend lithium battery lifespan while ensuring optimal performance. This section explores advanced care techniques and future charging innovations.

Advanced Battery Maintenance Strategies

Implementing these practices can double or triple your battery’s usable life:

| Maintenance Technique | Implementation | Benefit | Frequency |

|---|---|---|---|

| Capacity Calibration | Full discharge/charge cycle | Maintains accurate fuel gauge | Every 3 months |

| Deep Cycle Recovery | 0.1C charge for deeply discharged cells | Revives over-discharged batteries | As needed |

| Storage Voltage Maintenance | Keep at 3.7-3.8V (50% charge) | Minimizes electrolyte degradation | For storage >1 month |

Environmental and Safety Considerations

Lithium batteries require special handling due to their:

- Thermal Runaway Risk: Damaged cells can enter an unstoppable exothermic reaction at 150°C (302°F), releasing toxic fumes

- Recycling Challenges: Only 5% of lithium batteries are currently recycled due to complex disassembly requirements

- Transportation Regulations: Air shipment of lithium batteries over 100Wh requires UN38.3 certification

Emerging Charging Technologies

The future of lithium battery charging includes:

- Solid-State Chargers: New chargers designed for upcoming solid-state batteries with higher voltage tolerances (up to 5V)

- AI-Optimized Charging: Machine learning algorithms that adapt charging patterns based on individual battery wear patterns

- Pulse Charging: Experimental techniques using micro-pulses to reduce heat generation during fast charging

Cost-Benefit Analysis: While smart chargers cost 2-3× more than basic models, they typically pay for themselves by extending battery life 30-50%. For a $100 battery, a $30 quality charger provides better ROI than replacing batteries twice as often.

Professional Tip: Consider investing in a charger with refresh/recondition modes if working with older lithium batteries. These specialized cycles can recover up to 15% of lost capacity in aged cells.

Optimizing Charging Efficiency and System Integration

Maximizing lithium battery performance requires understanding the complex relationship between charging parameters, system design, and operational conditions. This section explores advanced optimization techniques and integration strategies for professional applications.

Precision Charging Parameters

Optimal charging requires balancing four critical variables:

- Voltage Accuracy: Must maintain ±0.5% tolerance (4.20V ±0.02V for standard Li-ion) to prevent under/overcharging

- Current Ramp Rates: Gradual current increases (0.1C steps) reduce internal resistance heating in high-capacity cells

- Temperature Compensation: Charge voltage should decrease by 3mV/°C when batteries exceed 25°C (77°F)

- Rest Periods: Incorporating 5-10 minute pauses during fast charging allows ion redistribution

System Integration Considerations

When integrating lithium batteries with other systems:

| Integration Point | Challenge | Solution |

|---|---|---|

| Solar Power Systems | Variable input voltage | MPPT controllers with lithium-specific algorithms |

| Vehicle Electrical Systems | 12V/24V system compatibility | Bi-directional DC-DC converters with isolation |

| Industrial Equipment | High vibration environments | Potted battery modules with strain relief |

Advanced Troubleshooting Guide

Common charging issues and diagnostic methods:

- Slow Charging: Check for increased internal resistance using DCIR measurement (ΔV/ΔI during pulse test)

- Premature Charge Termination: Verify balancing system operation – >50mV cell imbalance triggers safety cutoff

- Swelling: Measure outgassing with pressure sensors – >5kPa indicates electrolyte decomposition

Professional Optimization Tip: For mission-critical applications, implement adaptive charging that adjusts parameters based on:

- Historical cycle data

- Real-time impedance measurements

- Environmental conditions

This can improve cycle life by 40% compared to fixed-parameter charging.

Case Example: Data center UPS systems now use predictive charging that anticipates power demands, maintaining batteries at 70% charge during normal operation, then completing to 100% only before expected outages.

Comprehensive Risk Management and Quality Assurance for Lithium Battery Charging

Implementing robust safety protocols and quality control measures is essential when working with lithium battery systems. This section provides a complete framework for risk mitigation and performance validation throughout the battery lifecycle.

Risk Assessment Matrix

| Risk Category | Potential Impact | Mitigation Strategy | Verification Method |

|---|---|---|---|

| Thermal Runaway | Catastrophic failure (fire/explosion) | Multi-layer protection: PTC devices, CID, and BMS | Thermal abuse testing (UN38.3) |

| Overcharge | Electrolyte decomposition | Independent voltage monitoring circuits | HALT (Highly Accelerated Life Testing) |

| Cell Imbalance | Reduced capacity (20-40%) | Active balancing (≥100mA balance current) | Cycle testing with imbalance simulation |

Quality Assurance Protocols

Professional charging systems should implement these validation procedures:

- Pre-Charge Verification:

- Cell voltage differential check (<50mV variance)

- Internal resistance measurement (baseline comparison)

- Temperature sensor calibration verification

- In-Process Monitoring:

- Real-time Coulomb counting (charge/discharge balance)

- dV/dt analysis for early fault detection

- Infrared thermal imaging (5°C max gradient)

Advanced Performance Optimization

For mission-critical applications, implement:

- Adaptive Charging Profiles: Machine learning algorithms that adjust CC/CV parameters based on 100+ performance metrics

- Predictive Maintenance: Impedance spectroscopy trending to forecast capacity fade (±2% accuracy)

- Environmental Compensation: Dynamic adjustment of charge parameters for altitude (≥3000m) and humidity (≥80% RH)

Case Study: Aerospace applications use triple-redundant charging systems with cross-validated voltage measurements (0.1% accuracy) and mandatory 72-hour soak testing before flight clearance. This reduces failure probability to <0.001% per charge cycle.

Professional Recommendation: Establish a battery management database tracking:

- Cycle count history

- Capacity fade rates

- Charge efficiency trends

- Environmental exposure

This enables predictive replacement before performance degrades below operational requirements.

Conclusion

Charging lithium batteries safely requires understanding their unique chemistry and precise voltage requirements. As we’ve explored, standard chargers lack the critical safeguards needed to prevent overcharging, overheating, and potential hazards. The key takeaways include:

- Lithium batteries demand specialized chargers with CC/CV algorithms

- Temperature monitoring and voltage cutoff circuits are essential safety features

- Different lithium chemistries require specific charging parameters

- Proper maintenance significantly extends battery lifespan

For optimal safety and performance, always use a charger specifically designed for your lithium battery’s chemistry and specifications. Investing in quality charging equipment protects both your batteries and your safety – a small price for peace of mind and long-term cost savings.

Frequently Asked Questions About Charging Lithium Batteries

What’s the difference between lithium and lead-acid battery chargers?

Lithium battery chargers precisely control voltage (typically 4.2V/cell for Li-ion) and use CC/CV charging algorithms, while lead-acid chargers operate at higher voltages (14.4-14.8V) with different charge stages.

Lithium chargers also include temperature monitoring and cell balancing capabilities that standard chargers lack. Using a lead-acid charger on lithium batteries risks overcharging by 30-50% beyond safe voltage limits.

How can I tell if my charger is compatible with lithium batteries?

Check for explicit lithium chemistry labeling (Li-ion, LiFePO4) and verify voltage specifications match your battery. Quality lithium chargers will list supported chemistries, have adjustable current settings, and include multiple safety certifications (UL, CE). For example, a proper LiFePO4 charger should output exactly 3.65V per cell, not the 3.7V found in generic chargers.

What should I do if my lithium battery won’t charge?

First check voltage with a multimeter – below 2.5V requires specialized recovery charging at 0.05C. Verify charger compatibility and inspect for physical damage or swelling.

For multi-cell packs, measure individual cell voltages – imbalances over 0.1V prevent proper charging. Many smart chargers like the XTAR VC8 have recovery modes for deeply discharged cells.

Can I use a USB charger for small lithium batteries?

Only for single-cell batteries under 4.2V with proper protection circuits. Standard USB ports (5V/2.4A) require voltage regulation to avoid overcharging.

Quality USB lithium chargers like the Nitecore D2 include voltage conversion and automatic cutoff. Never charge bare lithium cells through USB without a dedicated charging module.

How does temperature affect lithium battery charging?

Lithium batteries should only charge between 0-45°C (32-113°F). Below freezing, lithium plating can occur, permanently damaging cells. Above 45°C, thermal runaway risk increases exponentially.

Professional chargers reduce current by 50% at 0°C and stop charging at 45°C. Always allow batteries to reach room temperature before charging after extreme exposure.

Is fast charging harmful to lithium batteries?

While 1C fast charging (full charge in 1 hour) is generally safe with quality batteries, it increases wear. For maximum lifespan, 0.5C charging (2 hours) is ideal.

Fast charging above 1C generates excessive heat – high-performance chargers like the SkyRC MC3000 use active cooling to mitigate this. Avoid fast charging if battery temperature exceeds 40°C (104°F).

How often should I balance charge multi-cell lithium packs?

Balance charge every 5-10 cycles for optimal performance. Modern BMS systems passively balance at 50-100mA during charging, but active balancing (300mA+) provides better results.

For critical applications like drones, use chargers with 1A balancing current. Always balance charge before storage to prevent voltage drift during inactivity.

What’s the safest way to store lithium batteries long-term?

Store at 40-60% charge (3.7-3.8V/cell) in fireproof containers at 15-25°C (59-77°F). Check voltage every 3 months – recharge to storage voltage if below 3.3V. For multi-cell packs, balance charge before storage. Never store fully charged batteries – at 100% charge, capacity degrades 4-8% per year even when unused.