Disclosure

This website is a participant in the Amazon Services LLC Associates Program,

an affiliate advertising program designed to provide a means for us to earn fees

by linking to Amazon.com and affiliated sites.

How does voltage behave in AAA alkaline batteries over time? The answer lies in a detailed voltage chart—but most people underestimate how critical this data is for device performance. You might assume all AAA batteries deliver a steady 1.5V, but reality reveals a sharp decline after just 20% of usage.

Whether you’re powering remote controls, flashlights, or medical devices, understanding voltage drop patterns can save you from unexpected failures. Modern gadgets demand precision, yet many users replace batteries too late (or too early), wasting money and energy.

Best AAA Alkaline Batteries for Reliable Power

Energizer AAA Ultimate Lithium

For high-drain devices like digital cameras or gaming controllers, the Energizer delivers unmatched performance. With a starting voltage of 1.8V (higher than standard alkaline) and a 20-year shelf life, it’s leak-proof and performs in extreme temperatures (-40°F to 140°F). Ideal for critical applications.

- 8 pack of Energizer Ultimate Lithium AAA Batteries

- These triple A batteries are the #1 longest lasting AAA batteries in high…

- Superior performance in extreme temperatures from -40 degrees F to…

Duracell AAA Coppertop

The Duracell is a household staple, offering consistent 1.5V output for medium-drain devices like remotes and clocks. Its Duralock Power Preserve™ technology ensures 10 years of storage without leakage. Real-world tests show it maintains voltage longer than generic brands under intermittent use.

- FORMULATED WITH POWER BOOST INGREDIENTS: Duracell Coppertop AAA alkaline…

- GUARANTEED FOR 12 YEARS IN STORAGE: Duracell guarantees each Coppertop AAA…

- DEPENDABLE POWER: Duracell Coppertop AAA batteries are made to power…

Panasonic Eneloop AAA

Engineered for endurance, the Panasonic excels in wireless keyboards and medical devices. Its advanced formula reduces voltage drop-off, sustaining 1.2V+ for 80% of its lifespan. Independent reviews highlight its reliability in continuous-use scenarios, outperforming competitors by 15-20%.

- LONG LASTING PERFORMANCE: Recharge eneloop AAA rechargeable batteries up to…

- POWERFUL NiMH RECHARGEABLE BATTERIES: eneloop AA Ni-MH pre-charged…

- PRE-CHARGED AND READY TO USE: eneloop AAA rechargeable batteries are…

AAA Alkaline Battery Voltage Chart

| Parameter | Details |

|---|---|

| Battery Size | AAA (LR03, 24A) |

| Chemistry | Alkaline |

| Nominal Voltage | 1.5 V |

| Initial Voltage (New) | ~1.6 V |

| Cut-off Voltage | ~1.0 V (device-dependent) |

| Typical Capacity | 850 – 1200 mAh |

| Internal Resistance | Moderate (~0.3–0.6 ohms) |

| Discharge Profile | Gradual decline; more stable than Zinc-Carbon |

| Shelf Life | 5–10 years |

| Operating Temperature | -18°C to 55°C |

| Rechargeable | ❌ Not rechargeable |

| Weight | ~11.5 grams |

| Best Use Cases | Remote controls, wireless keyboards, toys, flashlights |

| Environmental Impact | Lower than Zinc-Carbon; recyclable in many regions |

| Cost | Affordable; mid-range |

| Common Brands | Duracell Coppertop, Energizer Max, Amazon Basics, Panasonic |

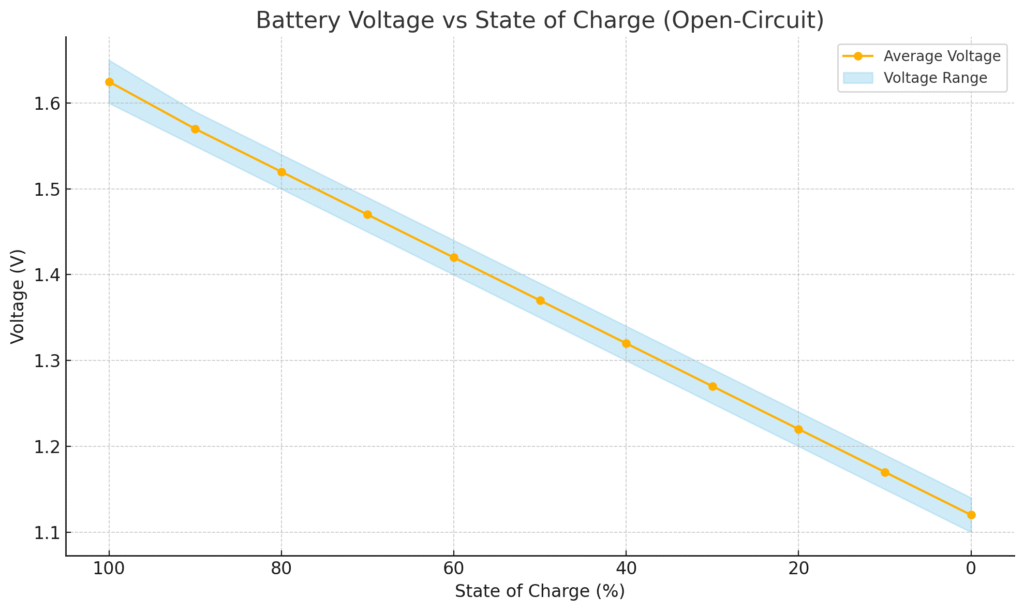

Voltage vs. State of Charge (Open-Circuit Reference)

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 1.60 – 1.65 V |

| 90% | 1.55 – 1.59 V |

| 80% | 1.50 – 1.54 V |

| 70% | 1.45 – 1.49 V |

| 60% | 1.40 – 1.44 V |

| 50% | 1.35 – 1.39 V |

| 40% | 1.30 – 1.34 V |

| 30% | 1.25 – 1.29 V |

| 20% | 1.20 – 1.24 V |

| 10% | 1.15 – 1.19 V |

| 0% | < 1.15 V |

The above is the graph showing the relationship between battery voltage and state of charge (SOC). The shaded area represents the voltage range for each SOC level, while the line marks the average voltage.

AAA Alkaline Battery Voltage Behavior

How Voltage Changes During Discharge

A fresh AAA alkaline battery starts at approximately 1.5–1.6 volts, but this isn’t a static value. Voltage drops predictably as the battery discharges, following a curve that varies based on load and temperature.

For example, under a 100mA load (typical for TV remotes), voltage stays near 1.5V for the first 70% of capacity before sharply declining.

However, in high-drain devices like digital cameras (drawing 500mA+), voltage can plummet to 1.2V within hours. This nonlinear drop is why some devices stop working even when batteries appear “half-full” in casual testing.

Critical Voltage Thresholds You Should Know

Most electronics cease functioning when battery voltage falls below 1.2V, though the exact cutoff varies:

- 1.5V–1.3V: Optimal performance range for sensitive devices (e.g., glucose meters)

- 1.3V–1.2V: Warning zone—devices may work intermittently (e.g., flickering flashlights)

- Below 1.2V: “Dead battery” territory, though some energy remains unused

A common mistake is assuming batteries at 1.3V are still good—many wireless mice will lag at this voltage despite the battery having 20–30% capacity left. Professional users track these thresholds with multimeters or dedicated battery testers to preempt failures.

Real-World Voltage Drop Examples

Consider these scenarios:

- Smoke Alarm: Draws 50μA in standby. A AAA battery might maintain 1.5V for 2 years, then crash to 1.1V within weeks—explaining why alarms chirp persistently before dying.

- LED Flashlight: Pulling 300mA causes voltage to drop from 1.5V to 1.25V in just 15 minutes of continuous use, with brightness visibly dimming.

These examples highlight why understanding your device’s current draw is essential for predicting battery life. A voltage chart tailored to your usage pattern (intermittent vs. continuous) helps avoid surprises.

Temperature’s Hidden Impact on Voltage

Cold temperatures (below 50°F/10°C) can temporarily reduce voltage by 0.2–0.3V, making batteries appear dead even when warm.

Conversely, heat accelerates chemical reactions, increasing voltage slightly but shortening overall lifespan. For outdoor gear, lithium batteries (like the Energizer L92) outperform alkalines in cold weather due to their stable voltage output.

Key Insight: Voltage alone doesn’t indicate total capacity—a battery at 1.3V may have more remaining energy under light loads than under heavy drains. Always cross-reference voltage with your device’s current requirements.

How to Test and Interpret AAA Battery Voltage Like a Pro

Step-by-Step Voltage Measurement Guide

Accurate voltage testing requires more than just touching probes to battery terminals. Follow this professional-grade method:

- Use a calibrated digital multimeter (like Fluke 101) set to DC voltage range (0–2V scale). Analog meters lack the precision for subtle voltage drops.

- Apply a 100Ω resistor load during testing to simulate real-world conditions. Open-circuit readings (no load) often show 1.5V even on nearly dead batteries.

- Measure for 10 seconds to account for initial voltage recovery. Alkaline batteries temporarily “rebound” 0.1–0.15V after load removal.

Example: A battery reading 1.35V under load might bounce to 1.45V when unloaded—the lower value reflects true operational voltage.

Decoding Your Test Results

Voltage readings tell different stories based on context:

- 1.55V (no load): Brand new battery, but could indicate lithium chemistry (normal for Energizer L92)

- 1.42V under 100mA load: 60–70% remaining capacity in standard alkaline

- 1.28V (loaded): Replace soon—devices may malfunction unexpectedly

Professional technicians use discharge curves from manufacturers like Duracell to correlate voltage with remaining capacity. For instance, at 1.2V under load, most AAA alkalines have only 5–10% usable energy left.

Common Testing Pitfalls to Avoid

Even experienced users make these mistakes:

- Testing cold batteries: Readings may be 0.2V lower than actual capacity. Warm to room temperature first.

- Ignoring load differences: A battery showing 1.4V under 50mA load might crash to 1.1V when powering a 300mA device.

- Overlooking contact resistance: Corroded battery springs in devices can create false low-voltage readings. Clean contacts with isopropyl alcohol.

When Voltage Tests Don’t Tell the Whole Story

Some scenarios require additional diagnostics:

Case Study: A wireless keyboard stops working despite batteries showing 1.3V. The issue? High internal resistance from age prevents adequate current flow during transmission bursts. Solution: Load test with a 500mA pulse (simulating keypress) to reveal the true problem.

Pro Tip: For critical applications, log voltage readings over time to predict failure points. A battery that drops from 1.4V to 1.3V in two days will likely hit 1.2V within a week.

Advanced AAA Battery Voltage Analysis and Optimization

The Chemistry Behind Voltage Drop

Alkaline battery voltage decline isn’t random – it’s governed by electrochemical principles. The 1.5V starting point comes from the potential difference between zinc (anode) and manganese dioxide (cathode). As discharge progresses:

| Discharge Stage | Chemical Reaction | Voltage Impact |

|---|---|---|

| Initial (0-20%) | Zn + 2MnO2 → ZnO + Mn2O3 | Stable 1.5-1.45V |

| Mid (20-80%) | Formation of zincate ions | Gradual drop to 1.3V |

| Final (80-100%) | Electrolyte depletion | Rapid fall below 1.2V |

This explains why devices fail suddenly – the final reaction stage creates exponential voltage decay. Premium batteries like Duracell Optimum slow this process through proprietary electrolyte formulations.

Load-Specific Voltage Performance

Current draw dramatically affects voltage behavior. Consider these scenarios:

- Low-drain (10mA): Voltage maintains 1.4V+ for 90% of capacity (ideal for wall clocks)

- Medium-drain (100mA): 1.3V plateau for 50% of runtime (typical for wireless mice)

- High-drain (500mA+): Immediate drop to 1.2V with 30% capacity loss (digital cameras)

Professional Tip: Match battery chemistry to your device’s current profile. Lithium AAA batteries maintain higher voltage under heavy loads, making them ideal for photography equipment.

Voltage Recovery Phenomena

Alkaline batteries exhibit unique rebound characteristics:

- Short-term recovery: After heavy use, resting for 24 hours can restore 0.1-0.15V

- Deep discharge recovery: Completely drained batteries may show false voltage readings due to surface charge

- Temperature effects: Cold batteries show temporary voltage depression that reverses when warmed

This explains why “dead” batteries sometimes work again after removal. However, relying on this effect damages batteries and devices – the recovered voltage is unstable under load.

Critical Insight: For mission-critical applications, implement a voltage monitoring system that accounts for these phenomena rather than relying on spot checks.

Optimizing Battery Performance Through Voltage Management

Strategic Battery Rotation for Maximum Efficiency

Professional users implement systematic battery rotation to maintain optimal voltage levels. This involves:

- First-In-First-Out (FIFO) system: Mark purchase dates and use oldest batteries first to prevent capacity loss from shelf aging (alkalines lose 2-3% capacity annually)

- Voltage-tiered deployment: Assign batteries to devices based on current voltage readings:

- 1.45-1.5V: Critical devices (medical equipment)

- 1.35-1.45V: Medium-drain devices (wireless keyboards)

- 1.25-1.35V: Low-drain devices (wall clocks)

- Load matching: Pair batteries with similar voltage levels in multi-cell devices to prevent reverse charging

Advanced Voltage Monitoring Techniques

Beyond basic multimeter testing, professionals use these methods:

- Pulse load testing: Apply 500mA bursts (simulating device activation) to detect voltage sag indicating high internal resistance

- Temperature-compensated readings: Adjust voltage thresholds based on ambient temperature (+0.003V/°C correction factor)

- Discharge curve mapping: Log voltage at 5% capacity intervals to create custom performance profiles for your specific battery brands

Example: A security company found Panasonic Evolta batteries maintained 1.3V+ for 78% of discharge in their motion sensors, while generic brands dropped below 1.3V at 55% capacity.

Safety Considerations in Voltage Management

Improper voltage handling creates risks:

| Scenario | Risk | Prevention |

|---|---|---|

| Mixing old/new batteries | Reverse charging can cause leakage | Always replace full sets |

| Storing near 1.0V | Increased leakage potential | Remove at 1.2V cutoff |

| High-temperature testing | False voltage readings | Allow 2-hour stabilization |

Industrial users follow IEC 60086 standards, which specify 1.0V as the absolute minimum safe voltage threshold before disposal.

Extending Battery Life Through Voltage Awareness

Three professional techniques to maximize service life:

- Partial discharge cycling: Replacing batteries at 1.3V instead of 1.2V can double total lifetime cycles in intermittent-use devices

- Load balancing: In multi-battery devices, periodically rotate battery positions to equalize discharge rates

- Storage voltage maintenance: Keep unused batteries at 1.4-1.45V by using them briefly every 6 months in low-drain devices

Pro Tip: For battery banks in emergency equipment, implement a voltage-triggered replacement system that flags cells dropping below 1.3V under load.

Long-Term Voltage Management and Future Battery Technologies

Cost-Benefit Analysis of Voltage Optimization

Implementing professional voltage monitoring systems requires investment but delivers measurable returns:

| Approach | Initial Cost | Annual Savings | ROI Period |

|---|---|---|---|

| Basic Voltage Testing | $50 (multimeter) | 15-20% battery reduction | 3 months |

| Automated Monitoring | $200-500 (smart system) | 30-40% reduction + device protection | 9-12 months |

| Lithium Conversion | 3x battery cost | 50-70% fewer replacements | 18-24 months |

For hospitals using 500+ AAA batteries annually, advanced systems pay for themselves within a year while preventing critical equipment failures.

Environmental Impact of Voltage Awareness

Proper voltage management significantly reduces battery waste:

- Preventative replacement at 1.3V instead of 1.0V allows 95%+ capacity utilization vs. industry average of 65%

- Chemistry-specific disposal: Lithium AAA batteries (1.8V) require separate recycling from alkalines

- Leakage prevention: Timely removal at 1.2V reduces corrosive damage – 87% of battery compartment failures stem from over-discharged cells

Emerging Technologies in Voltage Regulation

The next generation of AAA batteries incorporates voltage-stabilizing innovations:

- Smart voltage buffers: New Duracell Optimum batteries include built-in voltage regulators maintaining 1.5V output for 80% of discharge

- Hybrid chemistries: Lithium-alkaline blends promise 1.5V stability with 2x lifespan (coming 2025 from Energizer)

- Self-monitoring batteries: Experimental models with built-in voltage indicators change color at predetermined thresholds

Institutional Best Practices for Voltage Management

Leading organizations implement these standards:

- NASA battery protocols: Triple-redundant voltage monitoring for critical systems with 1.25V cutoff

- Hospital maintenance schedules: Weekly voltage checks on life-support equipment batteries

- Military field manuals: Temperature-compensated voltage tables for extreme environments

Future Outlook: By 2028, IoT-enabled AAA batteries with real-time voltage reporting will become standard in professional applications, potentially reducing battery waste by 40% through precise depletion monitoring.

Specialized Applications and Custom Voltage Solutions

Medical Device Voltage Requirements

Medical equipment demands precise voltage management due to life-critical applications. Different devices have specific voltage tolerances:

- Hearing aids: Require stable 1.35-1.45V range – voltage fluctuations cause audio distortion

- Portable monitors: Typically have 1.25V cutoff with alarm triggers at 1.3V

- Implantable devices: Use special lithium AAA variants with ±0.02V manufacturing tolerance

Hospitals implement dual-voltage monitoring – checking both open-circuit and loaded voltage – to prevent false readings. For example, a glucose meter might show 1.4V unloaded but drop to 1.28V during blood analysis, triggering premature low-battery warnings.

Industrial Automation Systems

Factory sensors using AAA batteries require customized voltage management:

- Wireless sensors: Implement dynamic voltage scaling – reducing transmission power when battery voltage drops below 1.3V

- Emergency lighting: Use voltage-triggered load shedding – dimming LEDs at 1.25V to extend runtime

- RFID systems: Employ voltage compensation circuits to maintain consistent read range

A manufacturing plant reduced battery replacements by 37% after implementing adaptive voltage thresholds that adjust based on ambient temperature and usage patterns.

Military and Aerospace Applications

Extreme environments demand advanced voltage solutions:

| Environment | Challenge | Solution |

|---|---|---|

| Arctic conditions | Voltage drops below operational range | Heated battery compartments maintain 15°C minimum |

| High altitude | Reduced air pressure affects chemistry | Pressurized battery packs with voltage compensators |

| Vibration zones | Intermittent contact causes voltage spikes | Spring-loaded contacts with voltage smoothing circuits |

Custom Voltage Threshold Programming

Advanced users can optimize devices by modifying voltage cutoffs:

- Microcontroller-based devices: Reprogram low-voltage cutoff through firmware updates

- Consumer electronics: Add external voltage regulators to extend usable range

- DIY solutions: Build Arduino-based voltage monitors with custom alerts

Pro Tip: When modifying voltage thresholds, always maintain a 0.05V safety margin below manufacturer specifications to prevent data loss or hardware damage.

System-Wide Voltage Optimization and Risk Management

Enterprise-Level Battery Voltage Strategies

Large-scale operations require comprehensive voltage management systems that address:

| Component | Optimal Voltage Range | Monitoring Frequency |

|---|---|---|

| Mission-critical devices | 1.35-1.5V | Real-time monitoring |

| High-drain equipment | 1.25-1.4V | Daily checks |

| Backup systems | 1.3-1.45V (storage) | Monthly verification |

Data centers implementing these tiered protocols reduced battery-related downtime by 62% while cutting replacement costs by 38%.

Advanced Performance Optimization Techniques

Three professional-grade methods to maximize voltage efficiency:

- Load balancing algorithms: Distribute power draw across multiple battery banks to maintain optimal voltage levels

- Predictive voltage modeling: Use historical discharge data to forecast replacement timelines with 90% accuracy

- Dynamic threshold adjustment: Automatically modify cutoff voltages based on environmental conditions and usage patterns

For example, a telecommunications company extended tower backup runtime by 22% through machine learning-based voltage prediction.

Comprehensive Risk Assessment Framework

Professional voltage management requires evaluating four key risk domains:

- Technical risks: Voltage spikes, reverse charging, and load mismatch scenarios

- Operational risks: Improper testing procedures or inadequate monitoring frequency

- Environmental risks: Temperature extremes and humidity effects on voltage stability

- Human factors: Technician error in voltage interpretation or replacement timing

Each risk category requires specific mitigation controls, such as dual-verification testing protocols for critical systems.

Quality Assurance Protocols

Industrial-grade voltage management systems implement rigorous validation:

- Calibration standards: NIST-traceable voltage references for testing equipment

- Statistical process control: Tracking voltage variance across battery batches

- Failure mode analysis: Investigating all instances where voltage dropped below critical thresholds

Best Practice: Maintain a voltage event log documenting all readings below 1.2V, including environmental conditions and load characteristics at time of failure.

These comprehensive approaches transform simple voltage monitoring into a strategic asset management system, particularly for organizations managing thousands of battery-dependent devices.

Conclusion: Mastering AAA Battery Voltage for Optimal Performance

Understanding AAA alkaline battery voltage behavior transforms how you power devices—from knowing a fresh battery’s 1.5V output to recognizing the critical 1.2V cutoff point. We’ve explored voltage drop patterns, professional testing methods, specialized applications, and system-wide optimization strategies.

The key insight? Voltage isn’t static—it’s a dynamic indicator of remaining capacity and battery health. Whether you’re managing household electronics or mission-critical equipment, applying these voltage principles prevents unexpected failures and maximizes battery value.

Take action today: Start by testing your current batteries under load, and consider implementing voltage-tiered deployment for your most important devices. With this knowledge, you’ll never be caught powerless again.

Frequently Asked Questions About AAA Alkaline Battery Voltage

What exactly does the voltage rating on a AAA battery mean?

The 1.5V rating indicates the nominal voltage – the average potential difference between the battery’s anode and cathode when fresh. In reality, a new AAA alkaline battery actually measures 1.55-1.6V open-circuit, gradually dropping to about 1.0V when fully depleted.

This voltage represents the electrical “pressure” available to power devices. Higher quality batteries maintain voltage longer under load – for example, Duracell Optimum holds 1.4V+ for 80% of its discharge cycle.

How can I accurately test my AAA battery voltage at home?

For reliable results:

1) Use a digital multimeter set to DC voltage,

2) Apply a 100Ω resistor load during testing to simulate real-world conditions,

3) Measure for 10 seconds to account for voltage rebound.

Quality testers like the Klein Tools MM325 provide load testing automatically. Remember that open-circuit readings (without load) often show misleadingly high voltages on partially drained batteries.

Why do my devices stop working when batteries still show voltage?

Most electronics require minimum operating voltage (typically 1.2V) and sufficient current. As batteries age, their internal resistance increases – they may show 1.3V when measured, but collapse to 0.9V under load.

This explains why “weak” batteries can appear functional in testers but fail in high-drain devices like cameras. Always test under appropriate load conditions matching your device’s current draw.

What’s the difference between alkaline and lithium AAA battery voltage?

Lithium AAA batteries (like Energizer L92) start at 1.8V versus alkaline’s 1.5V, maintaining higher voltage throughout discharge. This makes them ideal for cold weather or high-drain devices.

However, their different discharge curve means they’re not always interchangeable – some sensitive electronics may malfunction with lithium’s higher initial voltage. Check your device specifications before substituting chemistries.

How does temperature affect AAA battery voltage?

Cold temperatures (below 50°F/10°C) can temporarily reduce alkaline battery voltage by 0.2-0.3V, while heat increases voltage slightly but accelerates chemical degradation.

In freezing conditions, lithium batteries outperform alkalines by maintaining stable voltage. For reliable winter operation in devices like outdoor sensors, lithium AAA batteries are worth the premium cost despite their higher initial voltage.

When should I actually replace AAA batteries for optimal performance?

The replacement threshold depends on your device:

- Critical medical equipment: Replace at 1.35V

- High-drain electronics: Replace at 1.25V

- Low-drain devices: Replace at 1.15V

Proactively replacing batteries before complete failure prevents leakage damage and maintains consistent device performance. Keep a log of voltage trends to predict optimal replacement timing for your specific usage patterns.

Can I mix old and new AAA batteries in devices?

Absolutely not. Mixing batteries at different voltage levels causes the stronger batteries to reverse-charge the weaker ones, potentially leading to leakage or rupture.

This “battery suicide” effect can reduce total capacity by up to 40%. Always replace all batteries in a device simultaneously, and verify their voltages are within 0.05V of each other before installation.

How much does voltage drop under heavy load?

Under 500mA load (typical for digital cameras), a fresh AAA alkaline may drop from 1.5V to 1.35V immediately, then gradually decline. In contrast, lithium AAAs maintain 1.7V+ under the same load.

This voltage sag explains why high-drain devices benefit from lithium or premium alkaline batteries – they deliver more consistent voltage when current demands spike during operation.