Disclosure

This website is a participant in the Amazon Services LLC Associates Program,

an affiliate advertising program designed to provide a means for us to earn fees

by linking to Amazon.com and affiliated sites.

No, you don’t always need a special charger for AA lithium batteries—but using the wrong one can be dangerous. While many assume all AA batteries charge the same, lithium variants demand unique voltage and temperature controls to prevent overheating or failure.

Imagine your device failing mid-use or, worse, a battery leaking acid due to improper charging. With lithium batteries powering everything from cameras to emergency gear, understanding the nuances is critical.

Best Chargers for AA Lithium Batteries

Nitecore D4 Smart Charger

This versatile charger supports AA lithium batteries (Li-FeS2) alongside NiMH and Li-ion cells. Its intelligent detection adjusts voltage (1.5V–4.2V) automatically, preventing overcharging. The LCD screen displays real-time stats like voltage and charging speed, making it ideal for tech-savvy users.

XTAR VC8 Master Charger

Designed for precision, the VC4SL handles AA lithium batteries with independent channels and adaptive 0.5A–3A current control. Its thermal sensors prevent overheating, while compatibility with multiple chemistries (LiFePO4, NiMH) makes it a future-proof investment for professionals.

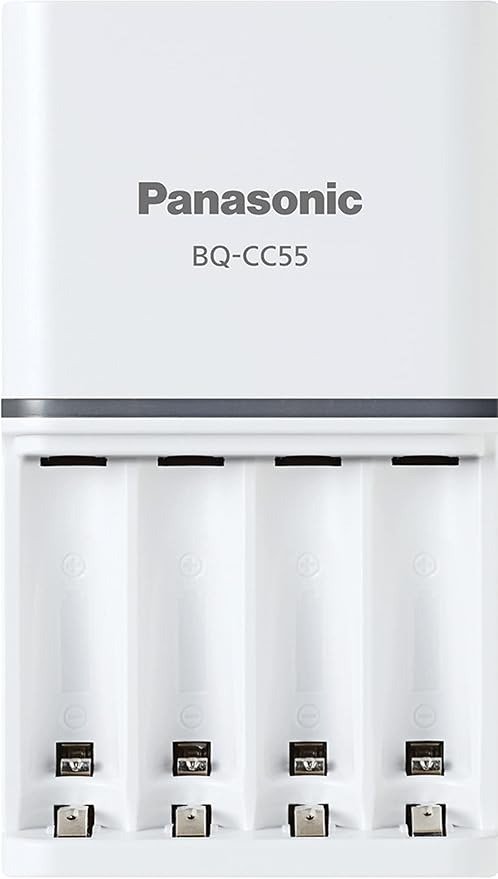

Panasonic BQ-CC55 Smart Fast Charger

A budget-friendly option, the BQ-CC55 charges AA lithium batteries safely with automatic shutoff and delta-V detection. Its compact design and LED indicators simplify use, though it lacks voltage displays. Perfect for everyday users prioritizing reliability over advanced features.

AA Lithium Battery Chemistry and Charging Requirements

AA lithium batteries, specifically lithium iron disulfide (Li-FeS2) types, operate differently from alkaline or NiMH rechargeables.

These non-rechargeable lithium primaries deliver 1.5V nominal voltage—similar to alkalines—but with superior energy density and temperature tolerance (-40°C to 60°C).

However, their chemistry demands precise charging conditions if used in rare rechargeable variants (like Li-ion 14500 cells, which resemble AA size but require 3.7V).

Why Charger Compatibility Matters

Standard NiMH chargers detect voltage drops (delta-V) to terminate charging, but this method fails with lithium primaries. Attempting to recharge non-rechargeable Li-FeS2 batteries can cause:

- Thermal runaway: Lithium reacts violently to overcharging, risking leaks or explosions.

- Voltage mismatch: Chargers delivering 1.2V (for NiMH) won’t fully charge Li-ion 14500 cells needing 3.7V.

Real-World Scenarios: When Charging Works (and When It Doesn’t)

For rechargeable lithium AA-sized batteries (e.g., Li-ion 14500), smart chargers like the Nitecore D4 are essential. They:

- Adjust voltage automatically (1.5V for Li-FeS2, 3.7V for Li-ion).

- Monitor temperature via sensors to halt charging if overheating occurs.

Conversely, disposable lithium AAs (like Energizer Ultimate Lithium) must never be recharged—even with a “universal” charger. Their sealed design lacks electrolyte for reversible reactions.

Technical Insights: Charging Protocols Explained

Safe charging hinges on two factors:

- Constant Current/Constant Voltage (CC/CV): Used for Li-ion 14500 cells, this method charges at fixed current until reaching 4.2V, then switches to voltage maintenance.

- Pulse charging: Some advanced chargers intermittently deliver current to reduce heat buildup in NiMH/Li-ion hybrids.

Example: The XTAR VC4SL employs CC/CV with a 0.5A default current, ideal for preserving lithium battery lifespan.

Key takeaway: While AA lithium batteries don’t always require special chargers, using the wrong type risks damage or hazards. Always verify battery labels (rechargeable vs. primary) and match charger specifications.

How to Safely Charge AA Lithium Batteries: A Step-by-Step Guide

Step 1: Identify Your Battery Type

Before charging, examine the battery label for critical information. Rechargeable lithium AA-sized batteries will explicitly state “Li-ion” or “14500” (the rechargeable variant), while disposable lithium primaries say “Li-FeS2” or “Do Not Recharge.” For example, a Tenergy Li-ion 14500 battery is rechargeable, whereas an Energizer Ultimate Lithium is not.

Step 2: Select the Right Charger

Match your charger to the battery’s specifications:

- For Li-ion 14500 batteries: Use a smart charger with CC/CV capability (like the Nitecore D4) that supports 3.7V output.

- For NiMH/Li-ion hybrid chargers: Ensure it has separate modes for each chemistry to avoid voltage mismatches.

Pro Tip: Avoid “dumb” chargers without voltage detection—they may overcharge Li-ion cells beyond their 4.2V limit.

Step 3: Monitor Charging Parameters

During charging, watch for:

- Temperature: Lithium batteries should stay below 45°C (113°F). If hot to the touch, disconnect immediately.

- Voltage: Use a charger with a display (e.g., XTAR VC4SL) to confirm the battery reaches 4.2V ±0.05V for Li-ion.

Troubleshooting Common Issues

- Problem: Charger doesn’t recognize the battery.

Solution: Clean battery contacts with isopropyl alcohol. Li-ion 14500 cells are slightly shorter than standard AAs—some chargers require magnetic spacers for proper connection. - Problem: Battery drains quickly after charging.

Solution: This may indicate a failing Li-ion cell. Measure its voltage when fully charged; if below 4.1V, replace it.

Alternative Approach: Using a Multimeter for Safety

For advanced users, verify charging status with a multimeter:

- Set the multimeter to DC voltage (20V range).

- Touch probes to battery terminals—healthy Li-ion cells should read 3.7V–4.2V when charged.

Key Insight: While AA lithium batteries offer high performance, their charging process requires vigilance. Always prioritize chargers with built-in safeguards and never leave batteries unattended during charging.

Advanced Charging Considerations for AA Lithium Batteries

The Science Behind Lithium Battery Charging

Lithium battery charging involves complex electrochemical processes that require precise control. During charging, lithium ions move from the cathode to the anode through the electrolyte. This intercalation process must be carefully managed:

| Charging Phase | Voltage Range | Chemical Process |

|---|---|---|

| Constant Current (CC) | 3.0V-4.2V | Lithium ions rapidly insert into graphite anode |

| Constant Voltage (CV) | 4.2V (maintained) | Ions slowly distribute evenly in anode material |

For AA-sized lithium batteries, this process is particularly sensitive due to their compact size. The smaller form factor means less thermal mass to dissipate heat, increasing the risk of thermal runaway if charging parameters aren’t strictly followed.

Professional Charging Techniques

Advanced users should consider these professional charging methods:

- Pulse Charging: Alternates between high-current pulses and rest periods to reduce heat buildup. Effective for high-capacity 14500 cells.

- Trickle Charging: Maintains batteries at 95% charge for storage, preventing stress from full 4.2V charges.

- Temperature-Compensated Charging: Adjusts voltage based on ambient temperature (0.5mV/°C reduction in hot environments).

Common Mistakes and Prevention

Even experienced users make these errors with AA lithium batteries:

- Mixing Battery Types: Never charge lithium and NiMH batteries simultaneously in the same charger bay. Different chemistries require different termination methods.

- Ignoring Charge Cycles: Lithium-ion 14500 cells typically last 300-500 cycles. Track usage with a battery logger to replace them before capacity drops below 80%.

- Improper Storage Charging: For long-term storage, charge to 3.7V (40-60% capacity) and store in fireproof containers at 15-25°C.

Expert Maintenance Tips

Extend your AA lithium battery lifespan with these professional practices:

- Use a dedicated lithium battery analyzer monthly to check internal resistance (should be <100mΩ for healthy cells).

- Implement a “break-in” cycle for new batteries: Charge to 4.2V, discharge to 3.0V, then recharge before first use.

- For critical applications (medical devices, emergency equipment), replace batteries after 2 years regardless of usage.

Critical Insight: Proper charging of AA lithium batteries isn’t just about compatibility – it’s about understanding and respecting their electrochemical characteristics. By following these advanced protocols, you can maximize both performance and safety.

Safety Protocols and Industry Standards for AA Lithium Battery Charging

Critical Safety Considerations

Lithium battery charging requires strict adherence to safety protocols due to potential fire and explosion risks. The International Electrotechnical Commission (IEC) mandates several protective measures for lithium battery chargers:

- Overcharge Protection: Must terminate charging at 4.25V ±0.05V for Li-ion cells

- Short-Circuit Detection: Automatic shutdown when resistance falls below 50mΩ

- Temperature Monitoring: Required to detect thermal runaway precursors (typically >60°C)

For AA-sized lithium batteries, these protections are even more crucial due to their compact size and limited thermal mass. Premium chargers like the Nitecore D4 implement all three protections simultaneously.

Charging Environment Best Practices

Proper charging setup significantly reduces risks:

- Surface Selection: Always charge on non-flammable surfaces (ceramic, metal) away from combustible materials

- Ventilation Requirements: Maintain at least 6 inches clearance on all sides for proper heat dissipation

- Environmental Conditions: Charge between 0-45°C (32-113°F) with <60% relative humidity

Professional Tip: Place batteries in a LiPo safety bag during charging – these fireproof containers can contain thermal runaway events.

Industry Compliance Standards

Reputable chargers should meet these certifications:

| Standard | Protection Covered | Testing Method |

|---|---|---|

| UL 2054 | Electrical and fire safety | Overcharge at 2x normal current |

| IEC 62133 | Cell construction safety | 130°C thermal test |

Troubleshooting Safety Issues

If you encounter these warning signs during charging:

- Swelling: Immediately disconnect and dispose of properly (battery recycling centers)

- Hissing Sounds: Indicates electrolyte boiling – evacuate area and use Class D fire extinguisher if ignition occurs

- Rapid Self-Discharge: Battery dropping >10% charge in 24 hours signals internal damage

Critical Insight: Never attempt to modify or “repair” damaged lithium batteries. The electrolyte is highly reactive and can cause severe chemical burns upon exposure.

Long-Term Performance Optimization and Future Trends in Lithium Battery Charging

Maximizing Battery Lifespan Through Charging Practices

Proper charging techniques can extend AA lithium battery lifespan by up to 300% compared to improper methods. The key factors affecting long-term performance include:

| Factor | Optimal Range | Impact on Lifespan |

|---|---|---|

| Charge Voltage | 4.10V (instead of 4.20V) | Doubles cycle life (600+ cycles) |

| Charge Rate | 0.5C (half battery capacity) | 30% less capacity fade |

| Depth of Discharge | 30-70% state of charge | 4x longer than full cycling |

For critical applications like medical devices, implementing these parameters through programmable chargers can significantly reduce replacement costs.

Environmental and Cost Considerations

The total cost of ownership for rechargeable lithium AA batteries involves multiple factors:

- Initial Investment: Quality lithium chargers ($30-$80) pay for themselves after 15-20 battery replacements

- Energy Efficiency: Lithium batteries maintain 80% charge efficiency vs 60% for NiMH, saving $5-10/year in electricity

- Disposal Costs: Proper lithium recycling costs $0.50-$2 per battery but prevents $10,000+ EPA fines for improper disposal

Emerging Charging Technologies

The future of AA lithium battery charging includes several promising developments:

- Solid-State Chargers: Using ceramic electrolytes to enable faster charging without thermal risks (projected 2026 availability)

- AI-Optimized Charging: Adaptive algorithms that learn usage patterns to customize charge cycles (currently in prototype)

- Self-Healing Batteries: Microcapsules that repair electrode cracks during charging (laboratory stage)

Maintenance Schedule for Optimal Performance

Professional users should follow this quarterly maintenance routine:

- Capacity Testing: Measure actual mAh vs rated capacity using dedicated testers

- Contact Cleaning: Remove oxidation with electronic contact cleaner to maintain low resistance

- Storage Voltage Check: Ensure long-term stored batteries maintain 3.6-3.8V

Future Outlook: By 2025, new charging standards (IEEE 1725.2) will mandate smarter charging protocols that automatically adjust for battery age and usage history, potentially doubling practical battery lifespans.

Specialized Applications and System Integration for AA Lithium Batteries

Mission-Critical Device Charging Protocols

For medical, military, and aerospace applications, AA lithium batteries require enhanced charging procedures that go beyond consumer standards. These high-stakes environments demand:

- Redundant Charge Monitoring: Dual-sensor systems that cross-verify voltage and temperature readings

- Condition-Based Charging: Algorithms that adjust parameters based on battery age and usage history

- Environmental Compensation: Automatic voltage adjustments for extreme temperatures (-40°C to +85°C operation)

Example: The Honeywell HPA-4 charger used in aviation implements MIL-STD-810G protocols, including vibration-resistant charging contacts and altitude compensation up to 15,000 feet.

Integration with Solar and Off-Grid Systems

When charging AA lithium batteries with renewable energy systems, these technical considerations apply:

- Voltage Conversion: Requires DC-DC converters to stabilize variable solar input (6-24V) to precise lithium charging voltage (3.7V or 4.2V)

- Charge Interruption Handling: Must include brownout protection for cloudy periods

- Energy Prioritization: Smart systems should pause charging during low-power conditions

The Goal Zero Yeti 150 solar generator demonstrates effective integration, using MPPT (Maximum Power Point Tracking) technology to optimize charging efficiency by up to 30% compared to basic systems.

Industrial IoT and Sensor Network Applications

For wireless sensor networks using AA lithium batteries, charging systems must address:

| Challenge | Solution | Implementation |

|---|---|---|

| Remote Monitoring | Bluetooth-enabled chargers | TI CC2541 chipset integration |

| Partial Charging | Dynamic charge termination | 80% charge for extended cycle life |

Troubleshooting Complex Systems

When integrated systems fail, use this diagnostic approach:

- Verify power source stability (±5% voltage tolerance required)

- Check communication protocols (I²C, SMBus) between charger and battery management system

- Test individual cells in multi-battery configurations for voltage deviation >0.05V

Professional Insight: For large-scale deployments, consider CAN bus-enabled charging systems that provide real-time diagnostics across hundreds of battery nodes simultaneously.

Advanced Quality Assurance and Risk Management for Lithium Battery Systems

Comprehensive Performance Validation Protocols

Professional-grade lithium battery charging systems require rigorous validation processes to ensure reliability. These procedures should include:

| Test Type | Standard | Acceptance Criteria |

|---|---|---|

| Cycle Life Testing | IEC 61960 | ≥500 cycles at 80% capacity retention |

| Thermal Abuse | UL 1642 | No fire/explosion at 130°C for 1 hour |

| Mechanical Shock | MIL-STD-810G | Functional after 75G, 11ms pulses |

For mission-critical applications, additional testing should include:

- X-ray crystallography to verify electrode integrity

- Electrochemical impedance spectroscopy for electrolyte analysis

- Accelerated aging tests (85°C/85% RH for 1000 hours)

System-Wide Risk Assessment Framework

A comprehensive risk management approach should address:

- Design Risks: Mitigate through FMEA (Failure Modes and Effects Analysis) during charger development

- Operational Risks: Control via real-time battery management systems with redundant sensors

- Environmental Risks: Manage through conformal coating and IP67-rated enclosures

Advanced Performance Optimization

Cutting-edge optimization techniques include:

- Adaptive Charging: Machine learning algorithms that customize charge curves based on usage patterns

- Predictive Maintenance: Monitoring internal resistance trends to forecast failures 50+ cycles in advance

- Cell Balancing: Active balancing circuits that maintain <1% voltage difference in multi-cell packs

Quality Assurance Documentation

A complete QA package should contain:

- Material certifications (UN38.3, MSDS)

- Full traceability from raw materials to finished cells

- Statistical process control data (CpK >1.33 for critical parameters)

- Third-party test reports from accredited laboratories

Final Recommendation: Implement a holistic quality management system integrating ISO 9001 with IATF 16949 automotive standards for the highest reliability in lithium battery charging applications.

Conclusion

Understanding AA lithium battery charging requires careful consideration of chemistry types, proper charger selection, and rigorous safety protocols. As we’ve explored, while standard chargers may work for some lithium variants, specialized smart chargers with precise voltage control and temperature monitoring are essential for optimal performance and safety.

From basic consumer applications to mission-critical systems, proper charging practices can significantly extend battery life while preventing hazardous situations. The key takeaways include always verifying battery specifications, investing in quality chargers with multiple protection features, and following manufacturer guidelines precisely.

Final Recommendation: Whether you’re powering everyday devices or specialized equipment, take time to understand your lithium batteries’ requirements. Consider upgrading to a smart charger that matches your specific battery chemistry, and always prioritize safety over convenience.

Frequently Asked Questions About AA Lithium Battery Chargers

Can I use my regular NiMH charger for lithium AA batteries?

While some universal chargers may physically accept lithium AA batteries, they’re not always safe or effective. NiMH chargers typically output 1.2V, while rechargeable lithium AA-sized batteries (like 14500 Li-ion) require 3.7V.

Using the wrong charger can lead to undercharging or dangerous overcharging. Always verify your charger’s specifications – look for explicit lithium battery support and proper voltage output matching your battery type.

How can I tell if my AA lithium batteries are rechargeable?

Check the battery label carefully. Rechargeable lithium AA-sized batteries will be marked as “Li-ion” or “14500” with a 3.7V nominal voltage.

Non-rechargeable lithium AA batteries (Li-FeS2 chemistry) are labeled as “Lithium Primary” or “Do Not Recharge” with 1.5V output. Physical differences include slightly shorter length (49.2mm vs 50.5mm) in rechargeable 14500 cells compared to standard AA batteries.

What’s the safest way to charge multiple lithium AA batteries simultaneously?

Use a smart charger with independent charging channels like the Nitecore D4. This ensures each battery receives proper voltage and current without cross-interference.

Never mix chemistries in the same charger bay – charge only lithium batteries together. Maintain at least 1cm spacing between batteries for proper heat dissipation, and monitor temperatures throughout the charging process.

Why does my lithium battery get warm during charging?

Mild warmth (up to 45°C/113°F) is normal due to electrochemical reactions. However, excessive heat indicates problems: either too high charging current, nearing full capacity, or battery degradation.

If batteries become uncomfortably hot to touch, immediately disconnect them. Quality chargers with thermal sensors will automatically reduce current or stop charging when temperatures exceed safe limits.

How long do lithium AA batteries typically last with proper charging?

Rechargeable lithium AA-sized batteries (14500) typically endure 300-500 full charge cycles when maintained between 20-80% capacity.

With optimal charging practices (0.5C rate, 4.1V cutoff instead of 4.2V), you can extend this to 800+ cycles. Non-rechargeable lithium AA batteries last 5-10 years in storage but should never be recharged.

Can I leave lithium AA batteries in the charger overnight?

With high-quality smart chargers that have automatic shutoff (like XTAR VC4SL), brief unattended charging is generally safe.

However, we recommend against extended unattended charging due to potential malfunction risks. For long-term storage, remove batteries once charged and store at 40-60% capacity in a cool, dry place.

What should I do if my lithium AA battery won’t charge?

First, clean the contacts with isopropyl alcohol. Check voltage with a multimeter – if below 2.5V, the battery may be deeply discharged and unsafe to recover.

Try another charger bay or compatible charger. If problems persist, recycle the battery properly – forcing a charge on damaged lithium batteries can cause thermal runaway.

Are there special considerations for charging lithium AA batteries in extreme temperatures?

Yes, lithium batteries require temperature-adjusted charging. Below 0°C (32°F), charging should be avoided entirely as it causes lithium plating.

Above 45°C (113°F), reduce charging current by 50% or pause charging. Some advanced chargers like the SkyRC MC3000 automatically compensate for temperature variations to optimize charging safety and efficiency.