Disclosure

This website is a participant in the Amazon Services LLC Associates Program,

an affiliate advertising program designed to provide a means for us to earn fees

by linking to Amazon.com and affiliated sites.

Yes, battery capacity increases when connected in parallel. But it’s not magic—it’s science. Parallel connections combine the amp-hour (Ah) ratings of batteries while keeping voltage the same.

Many assume wiring batteries differently boosts power magically. In reality, parallel setups unlock longer runtime, not higher voltage. This is crucial for applications like solar storage or EVs.

Best Batteries for Parallel Connections

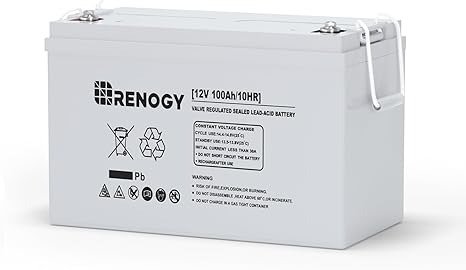

Renogy Deep Cycle AGM Battery 12V 100Ah

Ideal for solar and RV setups, the Renogy 12V 100Ah AGM battery offers high discharge rates and deep-cycle durability. Its spill-proof design and low self-discharge make it perfect for parallel configurations, ensuring stable power for extended periods.

Battle Born LiFePO4 12V 100Ah Lithium Battery

With a 3000-5000 cycle lifespan, the Battle Born LiFePO4 battery outperforms lead-acid options. Its lightweight design, built-in BMS, and 100% depth of discharge make it a top choice for parallel connections in marine and off-grid applications.

VMAXTANKS SLR125 AGM Deep Cycle Battery 12V 125Ah

The VMAXTANKS SLR125 provides exceptional capacity and vibration resistance, ideal for parallel setups in harsh environments. Its high cyclic stability and maintenance-free operation ensure reliable performance for backup power systems and renewable energy storage.

How Parallel Connections Increase Battery Capacity

When you connect batteries in parallel, their amp-hour (Ah) ratings add together while the voltage remains unchanged. For example, two 12V 100Ah batteries in parallel create a 12V 200Ah system. This effectively doubles your energy storage capacity, allowing devices to run longer before needing a recharge.

The Science Behind Parallel Battery Configurations

Parallel connections work by linking positive terminals to positive terminals and negative terminals to negative terminals.

This creates a single electrical circuit where current is shared between batteries. Unlike series connections (which increase voltage), parallel setups distribute the load evenly across all batteries, reducing strain on individual units.

Key characteristics of parallel connections:

- Capacity adds up: 2x 100Ah batteries = 200Ah total

- Voltage stays constant: 12V + 12V = 12V (not 24V)

- Current handling improves: More batteries share the load

Real-World Applications and Benefits

This configuration is ideal for applications requiring extended runtime without voltage changes. Common uses include:

- Solar power systems: Stores more energy for nighttime use

- RV/Marine setups: Powers appliances longer between charges

- Backup power: Extends UPS runtime for critical systems

A practical example: An off-grid cabin using three 12V 200Ah batteries in parallel gains 600Ah of storage. This means it can power a 500W load for nearly 12 hours (600Ah × 12V = 7,200Wh ÷ 500W = 14.4 hours, accounting for efficiency losses).

Important Considerations and Safety

While parallel connections increase capacity, they require careful implementation:

- Use identical batteries: Mixing capacities/chemistries causes imbalance

- Proper wiring is crucial: Unequal cable lengths create resistance differences

- Monitor charge levels: Batteries should discharge/charge at similar rates

Modern lithium batteries (like Battle Born’s models) often include built-in battery management systems (BMS) that automatically balance parallel connections, making them safer and more efficient than traditional lead-acid setups.

Proper Wiring Techniques for Parallel Battery Connections

Correct wiring is critical when creating parallel battery banks to ensure balanced current distribution and prevent dangerous imbalances. Poor wiring can lead to uneven charging, reduced efficiency, and even fire hazards in extreme cases.

Step-by-Step Parallel Connection Guide

- Match battery specifications: Use identical batteries (same voltage, capacity, age, and chemistry) to prevent one battery from overworking

- Prepare proper cables: Use thick, equal-length copper cables (minimum 4 AWG for 100Ah systems) to minimize resistance differences

- Connect positive terminals: Run a cable from Battery A’s (+) to Battery B’s (+) terminal

- Connect negative terminals: Similarly link (-) terminals using identical cable length and gauge

- Implement bus bars (for 3+ batteries): Use copper bus bars when connecting multiple batteries to maintain equal path resistance

Advanced Wiring Configurations

For systems with four or more batteries, professionals use diagonal or “X” wiring patterns:

- Diagonal method: Connect positive load to Battery A and negative load to Battery D, forcing current through all batteries equally

- Bus bar method: Install positive and negative bus bars, connecting all batteries with identical-length cables to the central bars

A real-world example: Marine systems often use the diagonal method with four 6V golf cart batteries (creating a 12V 400Ah bank). This ensures even wear when powering trolling motors for hours.

Critical Safety Measures

Always implement these protective measures:

- Install fuses: Place Class T fuses within 18″ of each battery’s positive terminal

- Use battery isolators: Prevents backcharging between banks in multi-system setups

- Monitor temperatures: Infrared thermometers can detect hot spots indicating resistance issues

Professional tip: Lithium batteries simplify wiring with built-in BMS protection, but still require proper gauge wiring. Battle Born’s 100Ah models, for instance, need minimum 2 AWG cables for optimal parallel performance.

Optimizing Performance in Parallel Battery Systems

Maximizing efficiency in parallel battery configurations requires understanding both electrical principles and practical system design. Proper optimization can extend battery life by 30-50% while maintaining peak performance.

Balancing Charge and Discharge Rates

Parallel batteries must maintain identical charge states to prevent current hogging, where one battery works harder than others. This imbalance accelerates wear and reduces total capacity. Key factors affecting balance include:

| Factor | Impact | Solution |

|---|---|---|

| Internal resistance | Varies by battery age and temperature | Use batteries from same production batch |

| Cable resistance | 0.1Ω difference can cause 15% imbalance | Measure resistance with milliohm meter |

| Terminal connections | Loose connections create hotspots | Torque to manufacturer specs (typically 5-8 Nm) |

Advanced Monitoring Techniques

Professional installations use these monitoring approaches:

- Individual battery monitors: Devices like the Victron BMV-712 track each battery’s state of charge

- Infrared imaging: Detects temperature variations >2°C between parallel batteries

- Shunt-based systems: Measure current flow through each parallel branch

Example: A solar storage system with six parallel 12V batteries should show less than 0.5V difference between any two batteries under 50A load.

Common Pitfalls and Expert Solutions

Even experienced installers make these mistakes:

- Mixing battery types: Never parallel AGM with lithium – use battery isolators if absolutely necessary

- Ignoring temperature effects: For every 10°C above 25°C, battery life halves – maintain active cooling

- Overlooking maintenance: Check torque on connections every 6 months (lugs loosen due to thermal cycling)

Pro tip: When expanding existing banks, add entire parallel sets rather than single batteries. For example, add two new batteries to two existing ones, keeping the total count even.

Advanced Parallel Battery System Maintenance and Troubleshooting

Maintaining parallel battery systems requires specialized knowledge beyond standard battery care. Proper maintenance can triple system lifespan while preventing dangerous failures.

Comprehensive Maintenance Schedule

Follow this detailed maintenance routine for optimal parallel battery performance:

- Weekly:

- Check voltage differentials between batteries (should be <0.2V at rest)

- Inspect terminals for corrosion (use baking soda solution for cleaning)

- Monthly:

- Perform capacity test on individual batteries (use 20-hour discharge test)

- Measure internal resistance with professional battery analyzer

- Quarterly:

- Retorque all connections to manufacturer specifications

- Check cable insulation for wear (especially in mobile applications)

Professional Troubleshooting Guide

When issues arise, use this systematic diagnostic approach:

- Identify symptoms: Note specific issues like reduced runtime or uneven heating

- Isolate components: Test each battery individually with load tester

- Check connections: Measure voltage drop across each connection point

- Analyze patterns: Look for correlation between issues and recent changes

Example: If Battery 3 consistently runs 5°C hotter than others, check:

- Connection tightness

- Cable resistance

- Internal cell balance (for lithium systems)

Safety Protocols and Industry Standards

Adhere to these critical safety standards:

| Standard | Requirement | Rationale |

|---|---|---|

| NFPA 70 Article 480 | 1/4″ clearance between battery terminals | Prevents arc flash incidents |

| IEEE 1187 | VRLA battery ventilation requirements | Prevents hydrogen accumulation |

| UL 1973 | Lithium battery safety testing | Ensures thermal runaway protection |

Expert tip: For large parallel banks (6+ batteries), implement a rotating maintenance schedule where you cycle batteries through different positions in the array to equalize wear patterns.

Long-Term Performance and Future Trends in Parallel Battery Systems

Understanding the lifecycle dynamics of parallel battery configurations is crucial for maximizing return on investment and anticipating technological advancements in energy storage solutions.

Lifecycle Analysis and Cost Considerations

Parallel battery systems exhibit unique aging characteristics that impact total cost of ownership:

| Battery Type | Parallel Cycle Life | Cost per kWh/cycle | Optimal Replacement Threshold |

|---|---|---|---|

| Flooded Lead-Acid | 300-500 cycles | $0.35-$0.50 | When capacity drops to 60% |

| AGM | 500-800 cycles | $0.25-$0.40 | When capacity drops to 70% |

| LiFePO4 | 3000-5000 cycles | $0.08-$0.12 | When capacity drops to 80% |

Example: A 24V 400Ah AGM system ($2,400) with 600 cycles at 70% depth of discharge provides 168,000Wh over its life, costing $0.014/Wh – 40% cheaper than single battery replacements.

Emerging Technologies and System Design

The parallel battery landscape is evolving with these significant developments:

- Smart parallel systems: New batteries like the Victron SuperPack automatically balance without manual configuration

- Modular architectures: Tesla’s Megapack design allows hot-swapping of parallel modules without system shutdown

- AI-driven management: Systems now predict failures by analyzing parallel performance patterns across thousands of cycles

Environmental and Safety Innovations

Modern parallel systems incorporate groundbreaking safety features:

- Thermal runaway containment: New ceramic separators prevent cascading failures in lithium banks

- Recyclability improvements: 95% of new lithium battery components are now recoverable

- Dynamic load sharing: Systems automatically redistribute loads during partial failures

Professional insight: Future systems will likely incorporate solid-state batteries in parallel configurations, offering 2-3x energy density while eliminating liquid electrolytes. Companies like QuantumScape are already testing 1000+ cycle prototypes.

Maintenance tip: For long-term parallel bank health, implement annual capacity rebalancing – discharging the entire bank to 20% SOC and charging at 0.2C rate to equalize all cells.

System Integration and Specialized Applications of Parallel Battery Banks

Parallel battery configurations enable unique system integrations that require specialized knowledge for optimal performance. These advanced applications push the boundaries of conventional energy storage solutions.

Hybrid Energy System Integration

Modern parallel battery banks frequently interface with multiple power sources, creating complex energy ecosystems:

- Solar+Generator Hybrids: Parallel batteries buffer intermittent solar production while providing surge capacity for generator starts

- Grid-Tied Microgrids: UL 1741 compliant systems use parallel banks for peak shaving and demand charge management

- Vehicle-to-Grid (V2G): Emerging standards like ISO 15118 enable EV battery packs to function as parallel grid resources

Example: A commercial facility using 4x 30kWh lithium banks in parallel with a 100kW solar array can achieve 97% renewable penetration while maintaining N+1 redundancy.

Specialized Configuration Techniques

Advanced applications require tailored parallel approaches:

- High-Availability Systems:

- Implement redundant parallel strings with automatic transfer switches

- Maintain one string at 100% SOC as hot standby

- Extreme Temperature Operations:

- Use heated/cooled battery enclosures with ±1°C precision

- Implement temperature-compensated voltage thresholds

- High-Vibration Environments:

- Utilize flexible bus bar connections with strain relief

- Install seismic battery racks with 5x design factor

Advanced Monitoring and Control

State-of-the-art parallel systems employ sophisticated monitoring:

| Parameter | Monitoring Method | Optimal Range |

|---|---|---|

| Inter-battery current | Hall-effect sensors | <5% of total load current |

| Temperature differential | RTD probes | <3°C between batteries |

| State of Health variance | Impedance spectroscopy | <5% deviation |

Professional tip: For mission-critical applications, implement a “Nested Parallel” design – creating parallel groups of parallel strings. This provides both capacity redundancy and fault tolerance.

Maintenance insight: When integrating with renewable systems, schedule monthly capacity tests during periods of lowest expected generation to establish true baseline performance.

Mastering System-Wide Optimization for Parallel Battery Arrays

Advanced parallel battery systems require holistic optimization strategies that account for electrical, thermal, and mechanical factors across the entire energy storage ecosystem.

Comprehensive Performance Optimization Framework

Maximizing parallel battery array efficiency involves balancing four critical dimensions:

| Optimization Area | Key Parameters | Advanced Techniques |

|---|---|---|

| Electrical | ≤2% voltage deviation ≤5% current imbalance | Dynamic impedance matching Active current redistribution |

| Thermal | ±1.5°C between cells ≤40°C maximum | Phase-change materials Liquid cooling loops |

| Mechanical | <0.1mm vibration displacement Proper torque retention | Vibration spectrum analysis Smart tension monitoring |

| Chemical | ≤3% SOC variance Balanced aging | Electrolyte additives Pulsed equalization |

Risk Assessment and Mitigation Protocols

Professional installations implement these comprehensive safety measures:

- Cascading Failure Prevention:

- Install pyro-fuse disconnects every 4 batteries

- Implement zone-based thermal isolation

- Cybersecurity:

- Encrypt BMS communications (AES-256 standard)

- Physical disconnect switches for critical systems

- Environmental:

- IP67-rated enclosures with HEPA filtration

- Hydrogen detection systems (0-1000ppm range)

Validation and Quality Assurance Procedures

Industry-leading installations follow this rigorous testing protocol:

- Pre-Commissioning:

- 72-hour burn-in at 50% load

- Infrared baseline imaging

- Performance Validation:

- Dynamic load testing (10-100% step changes)

- Capacity verification per IEEE 1188

- Long-Term Monitoring:

- Monthly impedance spectroscopy

- Quarterly capacity rebalancing

Professional insight: For mission-critical applications like data centers, implement a “3-2-1” redundancy strategy – three parallel strings, two active, one always in standby with automated testing.

Maintenance tip: Use predictive analytics by tracking 20+ parameters per battery (including charge/discharge curve shapes) to anticipate failures 3-6 months in advance.

Conclusion

Parallel battery connections effectively increase capacity while maintaining voltage, making them ideal for applications requiring extended runtime. We’ve explored how proper wiring, maintenance, and monitoring ensure balanced performance across all batteries in the array.

From basic configurations to advanced system integrations, parallel battery banks offer flexible solutions for solar storage, backup power, and specialized applications. The key lies in matching battery specifications, implementing proper safety measures, and following industry best practices.

As battery technology evolves, parallel systems are becoming smarter and more efficient. New lithium batteries with built-in BMS and emerging smart monitoring solutions are transforming how we design and maintain these systems.

Ready to optimize your energy storage? Start by assessing your power needs, then carefully plan your parallel battery configuration using the professional insights shared in this guide. Remember – proper implementation today means reliable power for years to come.

Frequently Asked Questions About Parallel Battery Connections

What exactly happens to battery capacity in parallel connections?

When connecting batteries in parallel, the amp-hour (Ah) capacities add together while voltage remains constant. Two 12V 100Ah batteries create a 12V 200Ah system. This effectively doubles your energy storage capacity, allowing devices to run twice as long before needing recharge.

The key principle is current sharing – each battery contributes equally to the total load. However, this requires identical batteries and proper wiring to prevent imbalance. Lithium batteries handle parallel connections better than lead-acid due to their flat discharge curves.

Can I mix different battery types in parallel?

Mixing battery types (like lithium and lead-acid) in parallel is strongly discouraged. Different chemistries have varying voltage characteristics, charge rates, and discharge profiles. This causes one battery to constantly overwork while another underperforms, leading to premature failure.

If absolutely necessary, use battery isolators or diodes to separate different battery types. Even then, the system won’t perform optimally. Always use identical batteries from the same manufacturer and production batch for parallel connections.

How do I properly wire batteries in parallel?

Use equal-length, thick gauge cables (minimum 4 AWG for 100Ah systems) to connect positive terminals together and negative terminals together. The ideal method is “diagonal wiring” where you connect the load to opposite corners of the battery bank.

For larger banks (4+ batteries), use copper bus bars with identical cable lengths to each battery. This ensures equal current distribution. Always torque connections to manufacturer specifications (typically 5-8 Nm) and use anti-corrosion compounds on terminals.

Why do my parallel batteries discharge unevenly?

Uneven discharge typically indicates mismatched batteries, wiring issues, or connection problems. Even small differences in internal resistance (caused by age, temperature, or manufacturing variances) can cause current imbalance. A 0.1Ω resistance difference can create 15% current imbalance.

Solutions include: using a battery balancer, checking all connections with a milliohm meter, and ensuring identical cable lengths. For lead-acid batteries, perform monthly equalization charges to rebalance the cells.

How many batteries can I safely connect in parallel?

The practical limit is typically 4-6 batteries for lead-acid and 8-10 for lithium (due to BMS protection). Beyond this, current imbalances become difficult to manage. Large systems should use multiple parallel strings with separate charge controllers.

Critical systems should implement redundancy – for example, creating two parallel banks of four batteries each, rather than one bank of eight. This provides fault tolerance if one battery fails.

Do parallel connections affect battery lifespan?

Properly configured parallel connections can extend battery life by reducing individual battery stress. However, improper setups accelerate aging through chronic under/overcharging of some batteries. Lithium batteries in parallel typically last longer than lead-acid in similar configurations.

To maximize lifespan, rotate battery positions annually, monitor individual battery health monthly, and replace entire parallel sets together rather than mixing old and new batteries.

What safety devices are needed for parallel battery banks?

Essential safety devices include Class T fuses on each battery (within 18 inches), a main disconnect switch, and proper ventilation. Lithium systems require a battery management system (BMS) for each parallel group.

Additional protection includes ground fault detection, hydrogen sensors for lead-acid banks, and thermal cutoff switches. Always install batteries in UL-listed enclosures with proper seismic bracing if in earthquake zones.

How do I calculate charging current for parallel batteries?

Total charging current equals the sum of recommended currents for each battery. For example, three 100Ah lithium batteries (recommended charge current 50A each) would need a 150A charger. Never exceed the manufacturer’s maximum charge rate.

Use multi-stage smart chargers that can adjust for parallel configurations. Some advanced chargers like the Victron Skylla-i can independently monitor and charge each parallel battery through separate connections.