Disclosure

This website is a participant in the Amazon Services LLC Associates Program,

an affiliate advertising program designed to provide a means for us to earn fees

by linking to Amazon.com and affiliated sites.

Calculating battery state of charge (SoC) is essential for maximizing performance and lifespan—but most people rely on guesswork or oversimplified methods.

You might assume a voltage reading alone gives an accurate SoC, but factors like temperature, age, and discharge rates dramatically impact results. Modern batteries demand precision, whether you’re maintaining an EV, solar storage system, or portable electronics.

Best Tools for Calculating Battery State of Charge

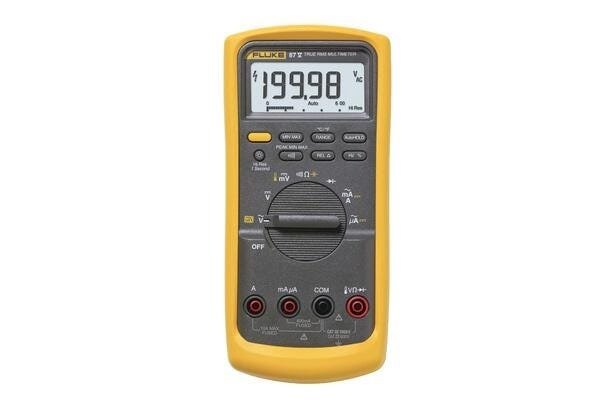

Fluke 87V Digital Multimeter

The Fluke 87V is a top-tier multimeter for measuring battery voltage with high precision (0.05% accuracy). Its True RMS sensing and temperature compensation ensure reliable SoC readings, especially for lead-acid and lithium-ion batteries. The rugged design and data logging make it ideal for professionals.

Victron Energy BMV-712 Battery Monitor

For advanced SoC tracking, the Victron BMV-712 uses Coulomb counting with a 0.1% resolution shunt. It integrates Bluetooth for real-time monitoring and includes temperature correction, making it perfect for solar systems, RVs, and marine applications where long-term accuracy is critical.

Klein Tools MM720 Auto-Ranging Multimeter

Budget-friendly yet reliable, the Klein MM720 offers auto-ranging voltage measurement (up to 600V) with a ±0.7% accuracy margin. Its compact design and built-in temperature probe help DIYers estimate SoC without complex setups, ideal for automotive and small-scale battery maintenance.

Battery State of Charge (SoC) Fundamentals

What Exactly Is State of Charge?

State of Charge (SoC) represents a battery’s remaining energy capacity as a percentage of its fully charged state. Unlike a fuel gauge in vehicles, which shows volume, SoC measures available electrochemical potential.

For example, a 100Ah battery at 50% SoC can deliver 50Ah before needing recharge. This metric is crucial because operating batteries outside their ideal SoC range (typically 20%-80% for lithium-ion) accelerates degradation.

Key Factors Affecting SoC Accuracy

Three primary variables influence SoC calculations:

- Voltage sag: High current draws temporarily lower voltage readings, misleading SoC estimates (e.g., a 12V lithium battery showing 11.8V under load might actually be at 60% charge, not 40%).

- Temperature: Cold temperatures increase internal resistance, causing voltage drops that don’t reflect true capacity. A -10°C environment can make a fully charged lead-acid battery appear 20% discharged.

- Battery age: As cycles accumulate, maximum capacity diminishes. A 5-year-old battery at “100% SoC” might hold only 70% of its original capacity.

Real-World Implications of SoC Miscalculations

Incorrect SoC readings have tangible consequences. Solar energy systems may shut down prematurely if controllers misjudge depth of discharge, while electric vehicles risk stranding drivers with inaccurate range predictions.

A study by the National Renewable Energy Lab found that 15% of lithium-ion battery failures stem from chronic undercharging due to flawed SoC algorithms.

The Voltage-SoC Relationship: Beyond Simple Tables

While voltage-based SoC charts exist (e.g., 12.6V = 100% for lead-acid), they’re oversimplified. Actual voltage curves vary by:

- Chemistry: LiFePO4 batteries maintain nearly flat voltage (3.2V/cell) between 90%-10% SoC, making voltage-only measurements useless in that range.

- Charge/discharge rate: A 0.5C discharge creates steeper voltage drops than 0.1C, requiring dynamic compensation.

Advanced systems use adaptive voltage modeling, where algorithms adjust curves based on historical performance data from battery management systems (BMS).

Why Resting Voltage Matters

For reliable voltage-based SoC, batteries need 4+ hours of rest after charging/discharging to stabilize. Automotive technicians often misdiagnose “dead” batteries because they check voltage immediately after engine cranking.

A rested 12.8V reading confirms 75% charge, while 12.4V indicates 50%—critical for troubleshooting parasitic drains.

Advanced Methods for Precise State of Charge Calculation

Coulomb Counting: The Gold Standard for Dynamic Systems

Coulomb counting (or current integration) measures actual energy flow by tracking current over time. Professional battery monitors like the Victron BMV-712 use a high-precision shunt resistor (typically 50-500μΩ) to log every amp-hour consumed. This method excels in applications with variable loads, such as:

- Electric vehicles during regenerative braking

- Off-grid solar systems with intermittent charging

- Marine applications with unpredictable power demands

However, it requires periodic full-cycle resets to compensate for accumulated errors (about 1-3% per month). Advanced systems automatically recalibrate when batteries reach 100% SoC during charging.

Implementing Coulomb Counting: A Step-by-Step Process

- Install the shunt: Connect between battery negative and system ground, ensuring all current flows through it (even 0.5A bypass can cause 5% error in small systems)

- Program battery capacity: Input exact Ah rating, accounting for age-related degradation (a 5-year-old 100Ah battery might be set to 85Ah)

- Set Peukert’s exponent: Adjust for non-linear discharge rates (typically 1.1-1.3 for lead-acid, 1.0 for lithium)

- Establish baseline: Perform full charge/discharge cycle while monitoring to validate accuracy

Hybrid Approaches: Combining Voltage and Current Data

Modern battery management systems (BMS) fuse multiple data streams using Kalman filters. For example, Tesla’s BMS weights voltage readings more heavily at charge extremes (0-10% and 90-100% SoC) while relying on coulomb counting in mid-range. This compensates for lithium batteries’ flat voltage plateau between 20-80% SoC where voltage-based estimation fails.

Overcoming Common Challenges

Temperature compensation remains critical – professional setups use:

- Integrated NTC thermistors (10kΩ at 25°C) mounted on battery terminals

- Algorithmic adjustments (0.3% SoC correction per °C for lead-acid below 20°C)

- Heated battery enclosures in sub-zero environments

For lead-acid batteries, specific gravity measurements (using refractometers) provide absolute SoC verification, though this isn’t feasible for sealed or lithium batteries.

Specialized Techniques for Different Battery Chemistries

Lithium-Ion Battery SoC Challenges and Solutions

Lithium-ion batteries present unique measurement difficulties due to their exceptionally flat discharge curves. Between 20-80% SoC, voltage may vary by just 0.1V per cell, making traditional voltage-based methods unreliable. Advanced BMS solutions employ:

- Open Circuit Voltage (OCV) profiling: Requires 30+ minutes of rest time for accurate readings

- Impedance tracking: Measures internal resistance changes that correlate with SoC

- Neural network prediction: Learns usage patterns to improve accuracy over time

| Chemistry | Voltage Range (per cell) | Recommended SoC Method |

|---|---|---|

| LiFePO4 | 3.0-3.6V | Coulomb counting + OCV calibration |

| NMC | 3.0-4.2V | Kalman filter hybrid approach |

Lead-Acid Specific Considerations

Flooded lead-acid batteries allow for specific gravity testing using a refractometer, providing absolute SoC verification. Key measurement points:

- Fully charged: 1.265 SG at 26°C

- 50% discharged: 1.190 SG

- Fully discharged: 1.120 SG

For AGM batteries, voltage-SoC correlation is temperature sensitive – a 12V battery at 25°C shows 12.7V at full charge, but only 12.58V at 0°C.

Professional Calibration Procedures

Accurate SoC systems require periodic recalibration:

- Full cycle calibration: Discharge to manufacturer-specified cutoff voltage, then full recharge

- Voltage matching: Compare BMS readings with laboratory-grade voltmeters

- Capacity testing: Measure actual energy delivery versus rated capacity

Common Mistakes to Avoid

Even experienced technicians often:

- Ignore surface charge effects (wait 4+ hours after charging for accurate readings)

- Use generic voltage-SoC tables without chemistry-specific adjustments

- Overlook Peukert effect in high-current applications

- Fail to account for parallel battery string imbalances

For mission-critical applications like medical equipment or aviation, consider professional-grade analyzers like the Midtronics EXP-1000 that combine conductance testing with adaptive algorithms.

Practical Implementation and Safety Considerations

System Integration Best Practices

Proper SoC monitoring system installation requires careful planning. For permanent installations, position current shunts on the negative terminal to minimize voltage drop interference.

Always use kelvin connections (4-wire measurement) for high-precision applications to eliminate wire resistance errors. In solar arrays, place monitoring equipment between the charge controller and battery bank rather than at load points to capture all energy flows.

Safety Protocols for Different Battery Types

Each chemistry demands specific precautions during SoC measurement:

- Lithium-ion: Never discharge below 2.5V/cell during testing – irreversible damage occurs below 2.0V

- Lead-acid: Wear acid-resistant gloves when checking specific gravity

- NiMH: Account for voltage depression effect after full discharge

Advanced Troubleshooting Techniques

When SoC readings become inconsistent:

- Verify sensor calibration: Compare shunt readings with a clamp meter at known loads

- Check for ground loops: Floating voltage measurements can cause 0.1-0.3V errors

- Test individual cells: A single weak cell can distort pack-level SoC calculations

Industry Standards and Compliance

Professional installations should adhere to:

- IEEE 1188 for lithium-ion battery monitoring

- IEC 62485 for lead-acid systems

- SAE J3072 for EV battery state estimation

Professional Tips for Accuracy Optimization

Seasoned technicians recommend:

- Performing monthly capacity tests to update battery aging profiles

- Using temperature-compensated hydrometers for flooded lead-acid batteries

- Implementing redundant measurement systems in critical applications

- Logging historical data to identify gradual capacity fade

For large-scale energy storage systems, consider distributed monitoring architectures where each battery module has independent SoC tracking that feeds into a central management system. This approach minimizes single-point failures and provides granular state awareness.

Long-Term Battery Health and Advanced SoC Management

Optimizing Battery Lifespan Through SoC Control

Strategic SoC management can extend battery life by 200-300% compared to uncontrolled usage. Lithium-ion batteries maintained at 40-60% SoC during storage show 5-10 times slower capacity fade than those kept at 100%. Implement these proven strategies:

- Partial cycling: Limiting discharge to 30-70% SoC range triples cycle life compared to 0-100% cycling

- Storage protocols: For seasonal storage, lithium batteries should be at 50% SoC with monthly top-up charges

- Temperature coordination: Maintain lower SoC (30-40%) in high-temperature environments to reduce degradation

| SoC Maintenance Strategy | Cycle Life Improvement | Implementation Cost |

|---|---|---|

| 30-70% cycling | 300% increase | Low (requires BMS programming) |

| Active cell balancing | 40% increase | Medium ($50-200 per battery pack) |

| Adaptive charging | 25% increase | High (requires smart charger) |

Advanced Predictive Maintenance Techniques

Modern battery analytics platforms use machine learning to predict SoC accuracy degradation before it becomes critical. These systems analyze:

- Charge/discharge curve shape changes over time

- Coulombic efficiency trends (typically drops below 95% before failure)

- Internal resistance growth patterns

Environmental and Safety Considerations

Proper SoC management directly impacts safety and sustainability:

- Thermal runaway prevention: Lithium batteries below 20% SoC are more prone to dendrite formation

- Recycling efficiency: Batteries retired at 80% original capacity can still serve 5-7 years in solar storage applications

- Transport regulations: IATA requires lithium batteries shipped at ≤30% SoC for air transport safety

Future Trends in SoC Technology

Emerging innovations include:

- Quantum battery sensors providing real-time molecular-level SoC data

- Self-calibrating solid-state batteries with inherent SoC indicators

- Blockchain-based battery health tracking for second-life applications

For mission-critical systems, consider investing in impedance spectroscopy equipment like the BioLogic VMP-300, which provides laboratory-grade SoC analysis by measuring electrochemical impedance across multiple frequencies.

System Integration and Smart Battery Management Solutions

Advanced BMS Architectures for Accurate SoC Tracking

Modern battery management systems employ multi-layered approaches combining hardware and software solutions. The most effective systems utilize:

- Distributed sensing networks: Individual cell monitors reporting to a central controller via CAN bus or daisy-chain connections

- Adaptive algorithms: Machine learning models that refine SoC estimation based on historical performance data

- Redundant measurement paths: Simultaneous voltage, current, and temperature monitoring with cross-validation

Integration with Energy Management Systems

For grid-tied or renewable energy applications, SoC data must interface with broader control systems:

- Protocol standardization: Using Modbus TCP, CANopen, or SunSpec Alliance communication protocols

- Dynamic load prioritization: Automatically shedding non-critical loads when SoC drops below predetermined thresholds

- Predictive charging: Coordinating with weather forecasts and tariff schedules to optimize charge cycles

Specialized Applications and Their Unique Requirements

Different use cases demand tailored SoC solutions:

| Application | Critical Requirements | Recommended Solution |

|---|---|---|

| Electric Vehicles | ±1% SoC accuracy at highway speeds | Kalman filter with vehicle dynamics input |

| Medical Backup | Zero downtime with SoC visibility | Redundant BMS with automatic failover |

| Marine Systems | Saltwater corrosion resistance | Fully potented IP68-rated monitors |

Optimization Techniques for Large-Scale Deployments

For battery farms or grid storage:

- Implement cell-level SoC balancing with active charge redistribution

- Use thermal imaging to identify hot spots affecting SoC accuracy

- Deploy digital twin technology for predictive SoC modeling

Troubleshooting Complex SoC Discrepancies

When integrated systems show inconsistent readings:

- Verify communication bus termination and shielding

- Check for firmware version mismatches between components

- Analyze timestamp synchronization across distributed systems

- Validate sensor sampling rates match system requirements

For industrial applications, consider professional-grade solutions like the Orion BMS from Ewert Energy Systems, which offers customizable SoC algorithms and seamless integration with SCADA systems.

Enterprise-Level Battery SoC Management and Validation

Industrial-Scale SoC Monitoring Architectures

Large battery installations require sophisticated monitoring frameworks that combine:

- Hierarchical BMS networks: Cell-level monitors feeding data to rack controllers, aggregated by master systems

- Time-synchronized data collection: Precision Time Protocol (PTP) synchronization to μs accuracy across all nodes

- Adaptive filtering: Real-time noise reduction algorithms for industrial environments

Performance Validation Protocols

Enterprise systems implement rigorous testing procedures:

| Test Type | Methodology | Acceptance Criteria |

|---|---|---|

| SoC Accuracy | Full discharge capacity test vs. BMS reported values | ±2% deviation maximum |

| Drift Validation | 30-day continuous operation without reset | <3% cumulative error |

| Cross-Validation | Comparison with reference lab equipment | ±0.5% voltage measurement difference |

Risk Mitigation Strategies

Critical systems employ multiple safeguards:

- Triple modular redundancy: Three independent SoC calculation paths with voting logic

- Fault tree analysis: Preemptive identification of single points of failure

- Graceful degradation: Automatic fallback to conservative estimates during system faults

Long-Term Performance Optimization

Sustained accuracy requires:

- Quarterly capacity verification tests with calibrated loads

- Annual sensor recalibration using NIST-traceable references

- Continuous algorithm tuning based on aging patterns

Quality Assurance Framework

Enterprise deployments typically implement:

- ISO 9001-compliant documentation procedures

- Automated regression testing for firmware updates

- Blockchain-based audit trails for critical measurements

Future-Proofing Considerations

Next-generation requirements include:

- AI-powered anomaly detection for early failure prediction

- Quantum-resistant encryption for data security

- Edge computing capabilities for real-time analytics

For mission-critical applications like data center UPS systems, solutions like Schneider Electric’s EcoStruxure provide enterprise-grade SoC management with 99.999% measurement availability guarantees.

Conclusion

Accurately calculating battery state of charge requires understanding multiple methodologies – from basic voltage measurements to advanced coulomb counting and hybrid algorithms. As we’ve explored, factors like battery chemistry, temperature, age, and load conditions all critically impact SoC accuracy.

Whether you’re maintaining an EV, solar array, or industrial battery bank, implementing the right monitoring tools and techniques can dramatically improve performance and lifespan. For optimal results, combine precise measurement hardware with proper calibration routines and chemistry-specific approaches.

As battery technologies evolve, staying informed about emerging SoC tracking methods will ensure your systems operate at peak efficiency. Start by auditing your current SoC measurement practices – small improvements today can yield significant long-term benefits.

Frequently Asked Questions About Calculating Battery State of Charge

What’s the most accurate method to measure battery SoC?

The gold standard is coulomb counting with periodic voltage calibration. This combines current integration (tracking amp-hours in/out) with occasional open-circuit voltage checks to reset accumulated errors.

Professional systems like the Victron BMV-712 achieve ±0.1% accuracy using precision shunts and temperature compensation. For lithium batteries, hybrid algorithms that incorporate impedance measurements provide the most reliable results.

Why does my battery show different SoC readings when charging vs discharging?

This voltage hysteresis effect occurs because internal resistance changes during charge/discharge cycles. A lithium battery might show 3.7V (60% SoC) when charging but 3.65V (55% SoC) under load.

Advanced BMS solutions compensate for this using dynamic resistance modeling and historical performance data to provide consistent readings.

How often should I recalibrate my SoC monitoring system?

For optimal accuracy:

- Lead-acid: Every 3 months or 20 cycles

- Lithium-ion: Every 6 months or 50 cycles

- Industrial systems: Monthly capacity verification

Always recalibrate after extreme temperature exposure or deep discharges.

Can I use the same SoC calculation method for all battery types?

Absolutely not. Key differences:

| Chemistry | Preferred Method |

|---|---|

| Lead-acid | Specific gravity + voltage |

| LiFePO4 | Coulomb counting + OCV |

| NMC | Kalman filter hybrid |

What causes sudden SoC reading jumps in my battery monitor?

Common culprits include:

- Ground loop interference (fix with isolated measurement)

- Shunt resistor overheating (use higher-rated 500A+ shunts)

- Software glitches (update BMS firmware)

- Cell balancing events (normal in lithium packs)

How does temperature affect SoC accuracy?

Temperature impacts both voltage readings and actual capacity:

- Below 0°C: Lithium batteries lose up to 30% capacity temporarily

- Above 40°C: Lead-acid voltage readings become unreliable

Quality monitors compensate with NTC thermistors (10kΩ at 25°C) mounted on battery terminals.

Is it worth investing in professional SoC monitoring equipment?

For critical applications, absolutely. A $500 industrial battery monitor pays for itself by:

- Extending battery life 2-3x through precise charging

- Preventing unexpected downtime

- Providing actionable degradation data

For casual users, mid-range units like the Renogy 500A provide good value.

Why does my new battery show less than 100% SoC after full charge?

This is normal and caused by:

- Manufacturer capacity buffers (typically 3-5%)

- Surface charge dissipation (wait 2-4 hours after charging)

- BMS calibration cycles (may take 5-10 full cycles to stabilize)

Only be concerned if capacity is >10% below rated specs.