Disclosure

This website is a participant in the Amazon Services LLC Associates Program,

an affiliate advertising program designed to provide a means for us to earn fees

by linking to Amazon.com and affiliated sites.

Did you know that nearly 30% of car breakdowns are caused by battery issues? Whether you’re troubleshooting a dead car battery, checking a solar power system, or maintaining a boat battery, knowing how to use a voltage meter on a 12V battery is an essential skill.

Many assume it’s as simple as touching probes to terminals, but improper technique can lead to false readings—or even damage.

Best Multimeters for Testing 12V Batteries

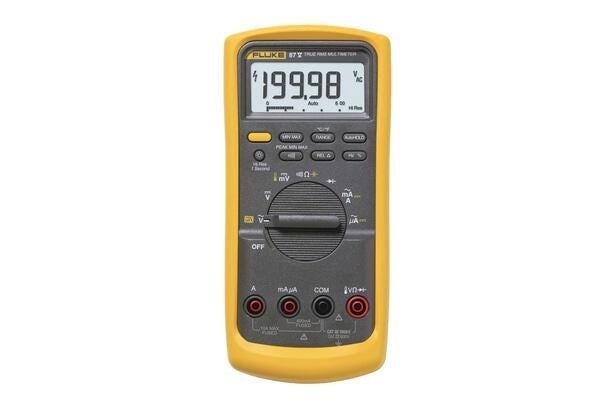

Fluke 87V Digital Multimeter

The Fluke 87V is a top-tier multimeter trusted by professionals for its precision and durability. It features True RMS voltage measurement, a high-contrast display, and robust construction—ideal for automotive and marine battery testing. Its accuracy (±0.05%) ensures reliable readings for 12V systems.

Klein Tools MM720 Auto-Ranging Multimeter

For a budget-friendly yet high-performance option, the Klein Tools MM720 excels with auto-ranging capability, a rugged design, and a built-in temperature probe. Its 600V CAT III safety rating and clear backlit display make it perfect for DIYers and mechanics alike.

Innova 3340 Automotive Digital Multimeter

The Innova 3340 is tailored for car batteries, featuring a dedicated 12V test mode, easy-to-read diagnostics (like “Good,” “Charge,” or “Replace”), and a compact design. It’s an excellent entry-level tool for home users who need straightforward, accurate battery health checks.

Voltage Readings for 12V Batteries

What Does a Healthy 12V Battery Actually Measure?

Many people assume a fully charged 12V battery should read exactly 12.0 volts, but this is a common misconception. In reality, a healthy, fully charged 12V lead-acid battery (the most common type) will measure between 12.6V and 12.8V when at rest.

This higher voltage reflects the chemical potential energy stored in the battery. When the engine is running, you should see 13.7V to 14.7V as the alternator charges the battery.

Interpreting Different Voltage Levels

Your voltage meter can reveal crucial information about your battery’s state:

- 12.6V-12.8V: Fully charged and in excellent condition

- 12.4V: About 75% charged – acceptable but may need charging soon

- 12.2V: Only 50% charged – risk of sulfation developing

- 12.0V or below: Severely discharged – immediate charging required

These readings apply when the battery has been at rest for at least 1 hour (called the “open-circuit voltage”). Testing immediately after driving will show artificially high readings from the alternator’s charge.

Why Surface Voltage Can Be Deceptive

A battery might show 12.4V but still fail under load. This happens when sulfation (crystal buildup on plates) creates high internal resistance. That’s why professional mechanics perform both:

- Static voltage test (what we’re covering here)

- Load test (measures voltage drop when powering a known load)

For example, a marine battery might read 12.5V but drop to 9V when trying to start an engine – a clear sign it needs replacement despite the decent surface voltage.

Temperature’s Impact on Voltage Readings

Battery voltage changes with temperature – about 0.01V per °F. A battery at 32°F (0°C) will read about 0.3V lower than the same battery at 80°F (27°C). This explains why cars struggle to start in winter – the chemical reactions slow down while the voltage drops.

Always consider ambient temperature when interpreting results. Many quality multimeters (like the Fluke 87V we recommended) include temperature compensation for more accurate diagnostics.

Step-by-Step Guide to Testing Your 12V Battery

Pre-Test Safety Precautions

Before touching your multimeter to the battery, these critical safety steps prevent accidents:

- Wear protective gear: Acid-resistant gloves and safety glasses protect against battery acid splashes

- Check for damage: Swollen cases or acid leaks mean immediate replacement – don’t test damaged batteries

- Remove metal jewelry: Rings or bracelets can cause dangerous short circuits across terminals

Remember that even a “dead” 12V battery can deliver hundreds of amps – enough to weld tools or cause severe burns if shorted accidentally.

Proper Multimeter Setup

Configure your multimeter correctly for accurate readings:

- Set to DC voltage mode (indicated by V with a straight line, not the wavy AC line)

- Select the 20V range for most digital multimeters (auto-ranging models do this automatically)

- Insert the black probe into the COM port and red probe into the VΩmA port

Pro tip: If your meter has a “REL” (relative) mode, press it after connecting to null out probe resistance for more precise measurements.

Taking Voltage Measurements

Follow this professional technique for reliable results:

- Connect the black probe to the negative terminal (usually marked “-” and black)

- Touch the red probe to the positive terminal (marked “+” and often red)

- Maintain contact for 10-15 seconds to observe voltage stabilization

For corroded terminals, clean first with a baking soda/water solution. Poor contact creates false low readings – a common mistake DIYers make. If testing a car battery, turn off all loads (lights, radio) and wait 10 minutes after engine shutdown.

Interpreting Results in Context

Combine your voltage reading with these diagnostic insights:

- After charging: A battery reading below 12.4V after overnight charging indicates sulfation or internal damage

- Under load: If voltage drops more than 1V when turning on headlights, the battery has reduced capacity

- Parasitic drain test: With car off, a reading above 50mA (0.05V voltage drop) suggests electrical system issues

Marine batteries should be tested both before and after a deep cycle to assess true capacity. Automotive batteries benefit from testing both at rest and during cranking.

Advanced Battery Diagnostics and Troubleshooting

Voltage Drop Under Load

While static voltage tests provide basic information, load testing reveals the battery’s true health. A proper load test requires:

| Battery Type | Test Load | Minimum Voltage | Duration |

|---|---|---|---|

| Standard Automotive | 50% of CCA rating | 9.6V at 70°F | 15 seconds |

| Deep Cycle Marine | 3x Ah rating | 10.5V | 20 minutes |

For example, testing a 600CCA car battery requires applying a 300A load. Professional shops use carbon pile testers, but you can approximate with headlights (about 10A) – a healthy battery should maintain above 11.5V with all lights on for 30 minutes.

Diagnosing Common Battery Issues

Voltage patterns reveal specific problems:

- Sulfation: Voltage drops rapidly under small loads but recovers quickly when load removed

- Internal short: Voltage remains abnormally low even after charging

- Cell imbalance: Voltage “bounces” between readings when probed repeatedly

Case in point: A battery reading 12.4V that drops to 8V when starting but recovers to 12.2V after indicates severe sulfation. One showing 10.5V constantly likely has a shorted cell.

Testing Battery Charging Systems

Complete diagnostics require checking the charging system:

- Measure base voltage (engine off)

- Start engine – should immediately jump to 13.8-14.7V

- Rev to 2000 RPM – voltage should remain stable

- Turn on loads (lights, AC) – should stay above 13.5V

A failing alternator often shows as voltage below 13.5V at idle or excessive fluctuation when loads change. Modern smart alternators may show different patterns – consult your vehicle manual.

Special Considerations for Different Battery Types

Testing protocols vary by battery chemistry:

- AGM batteries: Resting voltage up to 13.0V is normal

- Gel cells: Require slower charging – voltage spikes indicate damage

- Lithium-ion: Use specialized testers – standard voltage tests are unreliable

Always reference manufacturer specifications, as charging voltages for AGM batteries can be 0.5V higher than flooded lead-acid equivalents. Incorrect testing can void warranties on premium batteries.

Maintenance and Long-Term Battery Health Monitoring

Establishing a Battery Testing Routine

Professional-grade battery maintenance requires systematic testing intervals:

- Monthly checks: Basic voltage tests for all vehicles

- Seasonal tests: Comprehensive load tests before winter and summer

- Pre-trip inspections: Critical for RVs, boats, and off-grid systems

For example, marine batteries should be tested weekly during boating season, while seasonal vehicles need testing after long storage periods. Modern battery monitors like the Victron BMV-712 can automate this process with Bluetooth voltage tracking.

Advanced State of Charge Calculations

Accurate state-of-charge (SOC) determination requires more than simple voltage checks:

| Method | Accuracy | Equipment Needed | Best For |

|---|---|---|---|

| Voltage Correlation | ±15% | Basic Multimeter | Quick Checks |

| Specific Gravity | ±5% | Hydrometer | Flooded Batteries |

| Coulomb Counting | ±1% | Battery Monitor | Critical Systems |

For solar systems, combine voltage readings with amp-hour tracking for precise SOC. Lithium batteries require specialized battery management systems (BMS) for accurate monitoring.

Preventative Maintenance Techniques

Extend battery life with these professional practices:

- Equalization charging: Controlled overcharge (15.5V for flooded batteries) to remove sulfation

- Terminal maintenance: Annual cleaning with baking soda solution and protective grease application

- Storage protocols: Maintain 12.4V minimum during storage with maintenance chargers

Deep cycle batteries benefit from monthly full discharges to 50% followed by complete recharges. This prevents stratification in flooded batteries and maintains capacity in AGM units.

Interpreting Long-Term Voltage Trends

Tracking voltage patterns reveals developing issues:

- Gradual voltage drop: Indicates plate sulfation or electrolyte depletion

- Sudden voltage spikes: Suggests loose connections or failing voltage regulator

- Increasing charge times: Shows reduced battery capacity despite normal voltage

Commercial fleets often use telematics systems to track these metrics automatically, but DIYers can maintain simple spreadsheets with date, voltage readings, and environmental conditions for trend analysis.

Optimizing Battery Performance and System Integration

Voltage Thresholds for Different Applications

Optimal battery performance requires understanding application-specific voltage requirements:

| Application | Minimum Operational Voltage | Ideal Charging Voltage | Cutoff Voltage |

|---|---|---|---|

| Automotive Starting | 9.6V during cranking | 14.2-14.7V | 10.5V (deep discharge) |

| Solar Storage | 11.8V (50% DoD) | 14.4-14.8V (absorption) | 10.8V (80% DoD) |

| Marine Trolling | 12.0V continuous | 14.4V (temperature compensated) | 11.5V (cycle life protection) |

For instance, RV systems often use dual voltage thresholds – a higher cutoff (12.2V) for lithium batteries versus lower (11.8V) for lead-acid to preserve cycle life.

Advanced System Integration Techniques

Modern electrical systems require sophisticated voltage management:

- Voltage sensing relays: Automatically connect/disconnect auxiliary batteries at preset voltages (e.g., 13.2V connect, 12.7V disconnect)

- Smart alternators: Variable voltage output (12.8-15.2V) requiring compatible battery monitors

- DC-DC converters: Maintain stable 14.4V charging regardless of source voltage fluctuations

Example: A dual-battery overlanding setup might use a Redarc BCDC1225D charger to properly charge lithium auxiliary batteries from a smart alternator system.

Environmental and Safety Considerations

Voltage monitoring must account for:

- Temperature compensation: Add 0.003V/°C above 25°C for lead-acid charging

- Ventilation requirements: Hydrogen gas production increases above 14.4V

- Altitude effects: Reduced air density at elevation changes gassing thresholds

Professional installations in confined spaces (boats, RVs) often include hydrogen detectors and automatic ventilation systems triggered when voltage exceeds 14.6V for extended periods.

Future Trends in Battery Monitoring

Emerging technologies are transforming voltage monitoring:

- Cloud-connected monitors: Real-time voltage tracking via IoT (e.g., Victron VRM)

- AI-powered diagnostics: Machine learning algorithms predict failures from voltage patterns

- Solid-state sensors: Non-contact voltage measurement for safer high-voltage systems

These advancements enable predictive maintenance – detecting a failing battery from subtle voltage fluctuations weeks before traditional methods would notice issues.

Specialized Testing Scenarios and Advanced Diagnostics

Testing Batteries in Parallel and Series Configurations

When working with multiple battery setups, voltage measurement requires special considerations:

- Parallel systems: Measure each battery individually while disconnected – voltage variations >0.2V indicate imbalance

- Series configurations: Check each battery’s voltage under load – weak cells show disproportionate voltage drop

- Bank measurements: Always verify both individual and total bank voltage simultaneously

For example, in a 24V golf cart system with four 6V batteries, one battery reading 5.8V while others show 6.3V indicates a failing cell, even if total voltage appears normal at 24.4V.

Advanced Load Testing Methodologies

Professional-grade load testing goes beyond basic voltage checks:

- Dynamic load testing: Apply variable loads (20-200A) while monitoring voltage response curves

- Three-stage testing: Initial load (10 sec), recovery period (30 sec), secondary load (reveals capacity loss)

- Temperature profiling: Monitor case temperature during testing – excessive heat indicates internal resistance

Commercial battery analyzers like the Midtronics GR8 use conductance testing combined with voltage analysis to calculate actual CCA (Cold Cranking Amps) rather than just voltage drop.

Diagnosing Parasitic Drain Issues

Voltage measurements can identify abnormal power drains:

| Test Method | Procedure | Normal Reading | Trouble Threshold |

|---|---|---|---|

| Voltage Drop Test | Measure across fuses with circuit active | 0.00-0.02V | >0.05V drop |

| Current Draw Test | Multimeter in series with negative terminal | <50mA | >100mA |

Modern vehicles with complex electronics may show initial draws up to 2A that should taper off within 30 minutes as modules enter sleep mode.

Battery Management System (BMS) Diagnostics

When testing lithium batteries with integrated BMS:

- Voltage discrepancies: BMS may limit voltage during testing for protection

- Balancing cycles: Individual cell voltages should stay within 0.02V when fully charged

- Communication protocols: CAN bus or Bluetooth interfaces provide more data than voltage alone

Always reference manufacturer documentation, as some lithium systems intentionally show 0V when disconnected for safety reasons.

Comprehensive Battery System Health Assessment and Optimization

Integrated Voltage Analysis for System-Wide Diagnostics

A complete battery health assessment requires evaluating multiple voltage-related parameters:

| Parameter | Measurement Technique | Optimal Range | Failure Indicators |

|---|---|---|---|

| Resting Voltage | After 24h disconnection | 12.6-12.8V (lead-acid) | <12.4V after charging |

| Charge Acceptance | Voltage rise during charging | 0.5V/hour initial | <0.2V/hour rise |

| Voltage Recovery | Post-load rebound time | 90% recovery in 5 min | >15 min to recover |

For example, a solar battery bank showing 12.1V resting voltage, slow charge acceptance, and poor recovery likely has multiple failed cells requiring replacement.

Advanced Performance Optimization Techniques

Maximize battery lifespan through voltage management:

- Voltage profiling: Create custom charge curves based on usage patterns and temperature

- Micro-cycle management: Limit discharge cycles to 30-70% SOC for longest life

- Equalization scheduling: Automated monthly equalization charges based on voltage trends

Industrial applications often use adaptive charging algorithms that adjust voltage setpoints based on historical performance data and load patterns.

Comprehensive Risk Assessment Framework

Evaluate battery risks through voltage behavior analysis:

- Thermal runaway risk: Voltage fluctuations >0.5V/min without load change

- Connection faults: Voltage differences >0.3V between parallel strings

- Capacity fade: Voltage drop >15% faster than original specifications

Data centers typically implement redundant voltage monitoring systems with automated alerts for any abnormal voltage patterns.

Validation and Quality Assurance Protocols

Professional battery validation includes:

- Baseline voltage mapping: Document initial voltage performance characteristics

- Cycle testing: 50+ charge/discharge cycles with voltage logging

- Environmental stress testing: Voltage performance at temperature extremes

Manufacturers like Rolls Battery require full voltage discharge curves at multiple temperatures before approving warranty claims.

Conclusion

Mastering voltage meter testing for 12V batteries empowers you to accurately diagnose battery health, prevent unexpected failures, and extend battery lifespan. Throughout this guide, we’ve covered essential techniques from basic voltage measurements to advanced load testing, system integration, and long-term maintenance strategies.

Remember that proper voltage interpretation requires understanding your specific battery type, environmental conditions, and application requirements. Whether you’re maintaining a car, marine, or solar battery system, regular voltage monitoring serves as your first line of defense against battery-related issues.

Put this knowledge into action today – grab your multimeter, perform a comprehensive battery check using the methods outlined, and establish a routine testing schedule.

Frequently Asked Questions About Using a Voltage Meter on 12V Batteries

What’s the proper way to connect the multimeter to a 12V battery?

Always connect the black (negative) probe to the battery’s negative terminal first, then the red (positive) probe to the positive terminal. This sequence prevents accidental short circuits.

Ensure good metal-to-metal contact by cleaning corroded terminals with a wire brush. For most accurate readings, maintain contact for 10-15 seconds to observe voltage stabilization. Never reverse the connections as this can damage sensitive digital multimeters.

Why does my 12V battery show 12.8V when fully charged instead of exactly 12V?

This is completely normal and indicates a healthy battery. A lead-acid battery’s chemical composition actually produces 2.1V per cell (6 cells × 2.1V = 12.6V). The slightly higher voltage (12.8V) accounts for surface charge. When people refer to “12V batteries,” they’re using the nominal voltage – the average operating voltage, not the precise measurement you’ll see on a multimeter.

How can I tell if my 12V battery is bad using just a voltage meter?

While voltage alone doesn’t tell the whole story, warning signs include:

1) Voltage below 12.4V after overnight charging,

2) Rapid voltage drop when applying small loads (like headlights),

3) Inability to hold above 10.5V during cranking.

For conclusive testing, combine voltage checks with a load test or conductance test for comprehensive assessment.

What’s the difference between testing a car battery versus a deep cycle marine battery?

Car batteries are designed for brief high-current bursts (starting), while marine batteries endure deeper discharges. Test car batteries at rest and during cranking (should stay above 9.6V).

Marine batteries require testing under sustained loads (30-minute discharge test) and should maintain above 10.5V. The charging voltage also differs – marine systems often use temperature-compensated charging up to 14.7V.

Can I test a battery while it’s still connected to the vehicle?

You can, but results may be affected by parasitic drains or charging systems. For accurate resting voltage, disconnect the battery or test after the vehicle has been off for at least 1 hour.

However, testing while connected is useful for checking charging system output (should show 13.8-14.7V with engine running) or identifying parasitic drains (should be below 50mA with vehicle off).

Why does my battery voltage drop significantly when I turn on headlights?

A healthy 12V battery should drop no more than 0.3-0.5V when powering headlights (about 10A load). If you see drops exceeding 1V, this indicates:

1) Low state of charge,

2) Sulfation buildup increasing internal resistance, or

3) Deteriorated plates.

This voltage drop test is actually a simple way to assess battery condition without special equipment.

How does temperature affect my voltage readings?

Battery voltage decreases in cold temperatures (about 0.01V per °F below 80°F) and increases in heat. A battery reading 12.6V at 80°F might show 12.3V at 32°F – this is normal.

However, cold also reduces cranking power, so winter voltage tests should be more stringent. Many advanced battery chargers automatically compensate for temperature variations during charging.

Is it safe to test a damaged or leaking battery with a multimeter?

Exercise extreme caution with damaged batteries. While voltage testing is generally safe, leaking electrolyte can damage your multimeter and pose chemical hazards. Wear acid-resistant gloves and safety glasses.

Never test batteries with cracked cases or significant swelling. If you must test a questionable battery, do so in a well-ventilated area and avoid creating sparks near the battery.