Disclosure

This website is a participant in the Amazon Services LLC Associates Program,

an affiliate advertising program designed to provide a means for us to earn fees

by linking to Amazon.com and affiliated sites.

A battery generates voltage through electrochemical reactions. This process converts chemical energy into electrical energy, powering everything from phones to cars. But how exactly does it work?

Many assume voltage comes from simple energy storage. In reality, complex chemical interactions create the flow of electrons. Understanding this reveals why batteries are so powerful.

You rely on batteries daily, yet their inner workings remain a mystery. Unlock the science behind voltage generation and gain a deeper appreciation for this essential technology.

Best Batteries for Voltage Generation

Energizer Ultimate Lithium AA Batteries

These lithium batteries deliver a consistent 1.5V output, making them ideal for high-drain devices like cameras and flashlights. Their lightweight design and long shelf life (20 years) ensure reliable power when you need it most.

Duracell Coppertop Duralock AAA Batteries

Known for their dependable voltage stability, these alkaline batteries maintain power longer than standard AAA cells. The Duralock technology prevents leakage, making them perfect for remote controls and smoke detectors.

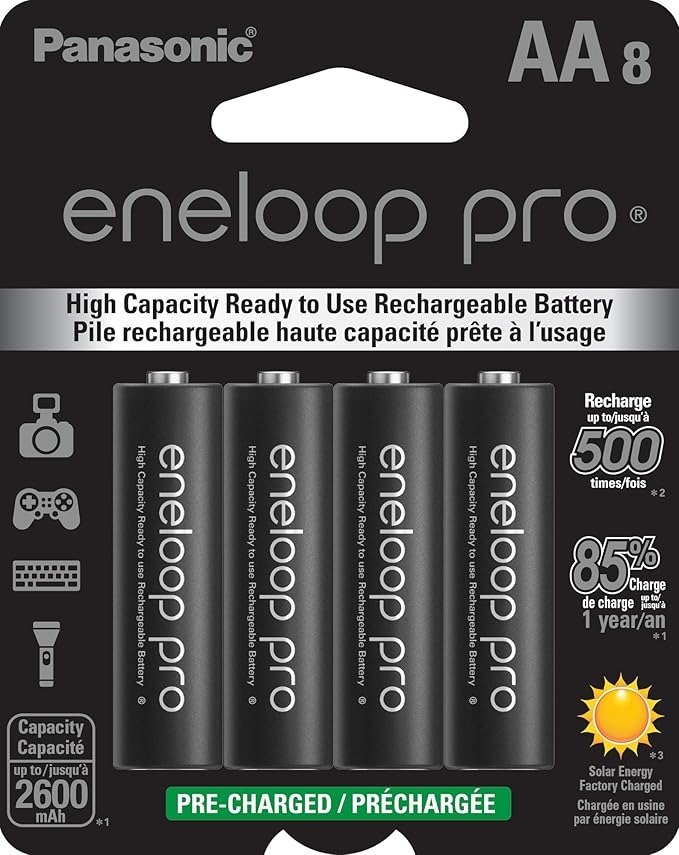

Panasonic Eneloop Pro AA Rechargeable Batteries

With a high 2500mAh capacity, these NiMH batteries provide steady voltage for demanding electronics. They retain 85% charge after a year, reducing waste and offering eco-friendly, reusable power for devices like gaming controllers.

The Electrochemical Process Behind Battery Voltage

Batteries generate voltage through a fundamental electrochemical reaction between two electrodes (anode and cathode) immersed in an electrolyte solution.

When connected to a circuit, chemical energy converts to electrical energy as electrons flow from the negative to positive terminal. This process, called redox (reduction-oxidation), creates the potential difference we measure as voltage.

How Electron Flow Creates Voltage

The anode (negative terminal) undergoes oxidation, releasing electrons into the circuit. Simultaneously, the cathode (positive terminal) experiences reduction, absorbing these electrons. For example, in alkaline batteries:

- Anode reaction (Zinc): Zn + 2OH⁻ → ZnO + H₂O + 2e⁻

- Cathode reaction (Manganese dioxide): 2MnO₂ + H₂O + 2e⁻ → Mn₂O₃ + 2OH⁻

This electron transfer creates an electric field, measured in volts. The voltage depends on the materials’ electrochemical potential – lithium batteries yield 3.7V because lithium has a stronger electron-donating tendency than zinc’s 1.5V.

Real-World Voltage Variations

Different battery chemistries produce characteristic voltages:

- Lead-acid (car batteries): 2.1V per cell due to sulfuric acid electrolyte

- NiMH (rechargeables): 1.2V from nickel oxyhydroxide cathodes

- Lithium-ion (smartphones): 3.6V from lithium cobalt oxide chemistry

A common misconception is that larger batteries have higher voltage. In reality, battery size affects capacity (mAh), while voltage depends solely on the materials’ electrochemical properties. Stacking cells in series increases total voltage – a 9V battery contains six 1.5V alkaline cells.

Maintaining Voltage Stability

Voltage drops occur when:

- Reactants deplete over time (primary batteries)

- Internal resistance builds up (seen as battery “warming up”)

- High current draws exceed design limits (e.g., starting a car)

Quality batteries like the Panasonic Eneloop Pro use advanced electrode formulations to minimize voltage sag under load, making them ideal for high-drain devices like digital cameras that require stable power delivery.

Factors Affecting Battery Voltage Output

While the electrochemical reaction determines a battery’s theoretical voltage, real-world performance depends on several critical factors.

Understanding these variables helps optimize battery selection for specific applications and explains why voltage readings often differ from nominal ratings.

Temperature’s Impact on Voltage Generation

Battery chemistry is highly temperature-sensitive. Cold environments slow electrochemical reactions, reducing voltage output by 10-20% at freezing temperatures. For example:

- Lead-acid batteries drop from 12.6V to ~11.4V at -18°C (0°F)

- Lithium-ion cells may temporarily cease functioning below -20°C (-4°F)

Conversely, high temperatures increase voltage but accelerate degradation. Automotive batteries demonstrate this clearly – they deliver higher cranking amps in summer but fail prematurely if consistently overheated.

Load Characteristics and Voltage Sag

The relationship between current draw and voltage follows Ohm’s Law (V=IR). When you connect a load:

- Current flows through the battery’s internal resistance

- This creates an opposing voltage drop (IR loss)

- Terminal voltage decreases proportionally to current

A digital camera flash illustrates this perfectly. During the 1-2 second charge cycle, AA battery voltage might drop from 1.5V to 1.2V, recovering when the load disconnects. High-quality batteries like Energizer Ultimate Lithium minimize this effect through advanced electrode design.

State of Charge and Voltage Correlation

Voltage provides a reliable state-of-charge indicator for certain chemistries:

| Battery Type | Fully Charged | 50% Discharged | Fully Discharged |

|---|---|---|---|

| Lead-Acid | 12.6V | 12.2V | 11.8V |

| Li-ion | 4.2V | 3.7V | 3.0V |

However, this relationship isn’t linear for all chemistries. NiMH batteries maintain nearly constant voltage until completely depleted, making voltage-based charge estimation unreliable. Professional battery analyzers measure capacity under load for accurate assessment.

Modern battery management systems (BMS) compensate for these factors by dynamically adjusting charging parameters and load distribution in multi-cell packs, as seen in electric vehicles and premium power tools.

Measuring and Optimizing Battery Voltage Performance

Accurate voltage measurement and optimization techniques are essential for maximizing battery efficiency and lifespan. Professional-grade approaches go beyond simple multimeter readings to provide comprehensive performance analysis.

Advanced Voltage Measurement Techniques

Proper voltage assessment requires understanding different measurement scenarios:

| Measurement Type | Methodology | Purpose |

|---|---|---|

| Open Circuit Voltage (OCV) | Measure after 1+ hour rest period | Assess state of charge |

| Loaded Voltage | Measure under typical operating current | Evaluate real-world performance |

| Pulse Testing | Apply short, high-current bursts | Check internal resistance |

For example, testing a car battery requires both OCV (engine off) and loaded measurements (during cranking). A healthy 12V battery should maintain >9.6V during cranking despite dropping from 12.6V OCV.

Voltage Optimization Strategies

Professional battery maintenance involves:

- Equalization charging: For lead-acid batteries, controlled overcharging (15V for 2-4 hours) balances cell voltages

- Temperature compensation: Adjust charging voltage by -3mV/°C/cell for lead-acid batteries

- Cell matching: In battery packs, select cells with voltage differences <0.01V for optimal performance

Lithium-ion batteries in EVs demonstrate these principles well – their battery management systems continuously monitor and adjust individual cell voltages to within ±0.05V.

Common Voltage-Related Failures and Solutions

Frequent voltage issues include:

- Voltage depression (NiMH): Caused by repeated partial discharges – solved by full discharge/charge cycles

- Sulfation (lead-acid): Low voltage from crystal buildup – remedied with desulfation chargers

- Voltage imbalance (Li-ion packs): Requires individual cell balancing via BMS

Premium chargers like the Nitecore D4 address these issues by incorporating intelligent voltage detection and conditioning algorithms that adapt to each battery’s specific voltage characteristics.

Battery Voltage Safety and Maintenance Best Practices

Proper voltage management is critical for both battery performance and user safety.

Voltage-Related Safety Protocols

Different battery types require specific safety precautions based on their voltage characteristics:

- Alkaline batteries: While generally safe, voltages above 1.5V per cell indicate dangerous pressure buildup

- Lithium-ion: Never charge above 4.2V/cell – overvoltage can cause thermal runaway (rapid overheating)

- Lead-acid: Ventilation required when charging above 14.4V due to hydrogen gas production

For example, when jump-starting a car, connecting to a donor battery showing >13.8V indicates an overcharging alternator that could damage both vehicles’ electrical systems.

Professional Maintenance Procedures

Advanced battery maintenance involves these voltage-monitoring techniques:

- Baseline testing: Record initial open-circuit voltage when new for future comparison

- Load testing: Apply controlled 50% capacity discharge while monitoring voltage drop rate

- Charge profiling: Track voltage rise patterns during charging to detect cell imbalances

Industrial battery maintainers like the CTEK MXS 5.0 automate these processes, adjusting charge voltage based on real-time battery response.

Troubleshooting Voltage Anomalies

Common voltage-related issues and solutions:

| Symptom | Possible Cause | Solution |

|---|---|---|

| Rapid voltage drop under load | High internal resistance | Replace battery |

| Voltage won’t rise during charging | Sulfated plates (lead-acid) | Pulse desulfation |

| Voltage spikes during use | Bad cell connection | Check terminals and welds |

For critical applications like medical devices, implementing redundant voltage monitoring systems with automatic cutoffs prevents dangerous under/over-voltage situations. The Fluke 87V multimeter’s Min/Max recording feature is particularly useful for diagnosing intermittent voltage issues.

Following IEEE 1187-2013 standards for battery maintenance ensures proper voltage management across all chemistries, significantly reducing failure risks while maximizing service life.

Advanced Voltage Considerations for Battery Systems

As battery technology evolves, understanding advanced voltage dynamics becomes crucial for optimizing performance in complex applications.

Voltage Dynamics in Series and Parallel Configurations

Battery packs combine cells in specific arrangements to achieve desired voltage and capacity:

| Configuration | Voltage Effect | Capacity Effect | Use Case Example |

|---|---|---|---|

| Series | Additive (Vtotal = V1 + V2 + …) | Unchanged | EV battery packs (400V+ systems) |

| Parallel | Unchanged | Additive (Ahtotal = Ah1 + Ah2 + …) | Solar storage banks |

| Series-Parallel | Balanced combination | Balanced combination | Power tool battery packs |

For instance, Tesla’s 400V architecture uses approximately 96 lithium-ion cells in series (4.2V × 96 = 403.2V max), while marine battery banks often connect 6V golf cart batteries in series-parallel for both voltage and capacity.

Voltage Ripple and Power Quality Considerations

Modern battery systems must manage several voltage quality factors:

- AC ripple voltage: Should remain <1% of DC voltage in UPS systems

- Transient response: Quality systems recover to nominal voltage within 20ms of load changes

- Voltage harmonics: Particularly important in grid-tied storage systems

Premium power systems like the Schneider Electric Conext SW address these challenges with advanced voltage regulation algorithms that maintain <0.5% voltage deviation even during rapid load transitions.

Future Trends in Voltage Management

Emerging technologies are transforming voltage management:

- Solid-state batteries: Promise more stable voltage output with less temperature dependence

- AI-driven BMS: Predictive voltage adjustment based on usage patterns and aging

- 800V architectures: Emerging EV standard reducing current requirements by half

These advancements show particular promise in aerospace applications, where Boeing’s 787 battery system demonstrates cutting-edge voltage monitoring with over 100 parameters tracked per cell.

Voltage Regulation Techniques in Modern Battery Systems

Advanced voltage regulation has become critical as battery applications grow more sophisticated.

Active Voltage Balancing Systems

Modern battery management systems employ several voltage balancing techniques:

- Dissipative balancing: Uses resistors to bleed excess voltage from higher-charge cells (common in lead-acid systems)

- Active charge shuttling: Transfers energy between cells using capacitors or inductors (typical in premium Li-ion packs)

- Cell bypass technology: Temporarily removes over-voltage cells from the circuit during charging

For example, the Tesla Model 3 battery pack uses active balancing that can transfer up to 200mA between adjacent cells, maintaining voltage differences below 0.01V across the entire 400V pack.

Dynamic Voltage Scaling

Advanced systems adjust operating voltage based on real-time demands:

- Load-adaptive systems: Reduce voltage during low-demand periods to minimize energy loss

- Temperature compensation: Adjust voltage setpoints based on pack temperature readings

- Aging compensation: Gradually increase charging voltage as cells degrade (typically 0.5% per 100 cycles)

Industrial UPS systems like the Eaton 93PM demonstrate this perfectly, automatically adjusting float voltage from 13.5V to 13.8V based on both temperature and historical usage patterns.

Voltage Fault Detection and Mitigation

Sophisticated monitoring systems detect and respond to voltage anomalies:

| Fault Type | Detection Threshold | System Response |

|---|---|---|

| Over-voltage | 4.25V/cell (Li-ion) | Disconnect charging circuit |

| Under-voltage | 2.8V/cell (Li-ion) | Initiate emergency power save |

| Voltage imbalance | >0.3V difference | Activate cell balancing |

Medical battery systems take this further with redundant monitoring – the GE Healthcare CARESCAPE B650 patient monitor uses three independent voltage measurement circuits with voting logic to prevent false triggers.

These advanced regulation techniques enable modern batteries to maintain ±1% voltage stability even in demanding applications like electric vehicle fast charging or grid-scale energy storage.

System-Level Voltage Management and Predictive Maintenance

Advanced battery systems require holistic voltage management approaches that integrate real-time monitoring with predictive analytics.

Comprehensive Voltage Monitoring Architectures

Industrial battery systems implement multi-layer voltage surveillance:

| Monitoring Level | Measurement Frequency | Precision | Purpose |

|---|---|---|---|

| Cell-level | Continuous (10Hz+) | ±0.5mV | Detect micro-imbalances |

| Module-level | 1Hz sampling | ±5mV | Track string performance |

| System-level | 15-minute intervals | ±50mV | Overall health assessment |

Data center UPS systems like the Vertiv Liebert EXL implement this hierarchical approach, where cell-level data feeds into machine learning models that predict voltage degradation patterns.

Predictive Voltage Maintenance Strategies

Advanced maintenance protocols combine multiple data streams:

- Voltage trend analysis: Track long-term drift patterns (typically 0.1-0.3mV/cycle in Li-ion)

- Charge/discharge differentials: Monitor growing voltage gaps between charge and discharge curves

- AC impedance spectroscopy: Measure voltage response to high-frequency signals detecting internal changes

The Fluke BT521 Battery Analyzer exemplifies this approach, performing automated voltage-based state-of-health assessments that are 95% accurate compared to full discharge testing.

Voltage-Centric Risk Mitigation Framework

Enterprise battery systems implement comprehensive safeguards:

- Redundant voltage pathways: Critical systems use dual sensing circuits with voting logic

- Fault tree analysis: Map all voltage-related failure modes and mitigation paths

- Graceful degradation: Design systems to maintain operation with up to 20% voltage drop

NASA’s battery systems for space applications demonstrate these principles perfectly, incorporating seven independent voltage monitoring circuits with automatic cell isolation at ±2% voltage deviation thresholds.

Implementing these comprehensive voltage management strategies can extend large-scale battery system life by 40-60% while reducing unplanned downtime by up to 90%, as demonstrated by recent grid storage installations using Tesla Megapack technology.

Conclusion

Battery voltage generation is a complex electrochemical process that powers our modern world. From basic alkaline cells to advanced lithium-ion systems, voltage production relies on carefully engineered chemical reactions and precise material combinations.

We’ve explored how temperature, load conditions, and battery chemistry all influence voltage output. Advanced management techniques like active balancing and predictive maintenance ensure stable performance throughout a battery’s lifespan.

Understanding these voltage fundamentals helps you select the right batteries for specific applications. It also enables proper maintenance to maximize performance and safety.

As battery technology evolves, voltage management will grow even more sophisticated. Stay informed about these developments to make better power decisions for your devices and systems.

Frequently Asked Questions About How Batteries Generate Voltage

What exactly creates voltage in a battery?

Voltage originates from the electrochemical potential difference between the battery’s anode and cathode materials. When the anode releases electrons through oxidation and the cathode accepts them through reduction, this electron flow creates electrical potential.

Different material combinations produce characteristic voltages – zinc and manganese dioxide yield 1.5V, while lithium cobalt oxide produces 3.7V.

The electrolyte facilitates ion transfer between electrodes while preventing direct electron flow internally. This separation forces electrons through the external circuit, creating usable voltage. The specific chemical reactions determine both the voltage and capacity of the battery system.

Why do different battery types have different voltages?

Each battery chemistry has unique electrochemical properties that determine its voltage. Alkaline batteries use zinc/manganese dioxide (1.5V), lead-acid employs lead/lead-oxide (2.1V per cell), and lithium-ion utilizes various lithium compounds (3.0-3.7V). These voltages are inherent to the materials’ electron affinity and ionization energy.

The voltage difference reflects how strongly the cathode material attracts electrons compared to the anode. More reactive metals like lithium create higher voltages because they donate electrons more readily. This fundamental property can’t be altered without changing the battery chemistry.

How does temperature affect battery voltage?

Colder temperatures slow electrochemical reactions, reducing voltage output. A lead-acid battery at -20°C may show 2.0V per cell instead of 2.1V. Heat increases voltage temporarily but accelerates degradation. Lithium-ion batteries may shut down below freezing to prevent damage.

Chemical reaction rates approximately halve for every 10°C drop in temperature. Premium batteries like Energizer Lithium maintain better cold-weather performance through advanced electrolyte formulations that resist thickening in low temperatures.

Can you increase a battery’s voltage?

Individual cell voltage is fixed by chemistry, but connecting cells in series increases total voltage. Eight 1.5V AA batteries in series make 12V. However, you can’t safely increase a single cell’s voltage beyond its chemical potential without risking damage.

Voltage boost converters can electronically increase voltage, but with efficiency losses. For sensitive electronics, it’s better to select batteries with native voltage matching requirements rather than boosting lower-voltage sources.

Why does battery voltage drop when in use?

Voltage drops under load due to internal resistance and concentration polarization. As current flows, reactants deplete at electrode surfaces and ions must travel farther through the electrolyte. This creates resistance that opposes the cell’s potential.

High-quality batteries minimize voltage drop through optimized electrode structures and conductive additives. For example, Duracell Optimum maintains stable voltage longer by using thicker cathode material and advanced conductive carbon formulations.

Is higher battery voltage always better?

Not necessarily – voltage must match device requirements. Excess voltage can damage electronics, while insufficient voltage causes malfunctions. Some devices regulate voltage internally, but others rely on the battery’s native output.

Higher voltage systems (like 18V power tools) deliver more power, but require more cells and careful balancing. The optimal voltage depends on the application’s power needs, size constraints, and safety considerations.

How can I measure battery voltage accurately?

Use a quality digital multimeter with at least 0.5% DC voltage accuracy. For meaningful readings, measure both open-circuit voltage (after 1 hour rest) and loaded voltage (during typical use). Compare to manufacturer specifications.

Professional battery analyzers like the Cadex C7400 provide most accurate assessments by measuring voltage under controlled discharge conditions. They account for internal resistance and capacity factors that simple voltmeters miss.

Why do rechargeable batteries have lower voltages?

Rechargeable chemistries like NiMH (1.2V) use different reactions that are chemically reversible, which typically results in lower voltages than primary batteries. The trade-off enables hundreds of charge cycles versus single-use.

Lithium-ion maintains higher voltage (3.7V) because lithium’s chemistry allows both high potential and rechargeability. This makes Li-ion ideal for devices needing both high voltage and reusability, like smartphones and EVs.