Disclosure

This website is a participant in the Amazon Services LLC Associates Program,

an affiliate advertising program designed to provide a means for us to earn fees

by linking to Amazon.com and affiliated sites.

A healthy 12V battery should read 13.7–14.7 volts when the engine is running. But here’s the catch: many drivers assume their battery is fine if the car starts, only to face sudden failures later.

Modern vehicles rely on precise electrical systems, and even a slight voltage drop can hint at hidden problems—from failing alternators to parasitic drains. Imagine being stranded with a dead battery because you missed the warning signs.

Best Multimeters for Testing 12V Battery Voltage

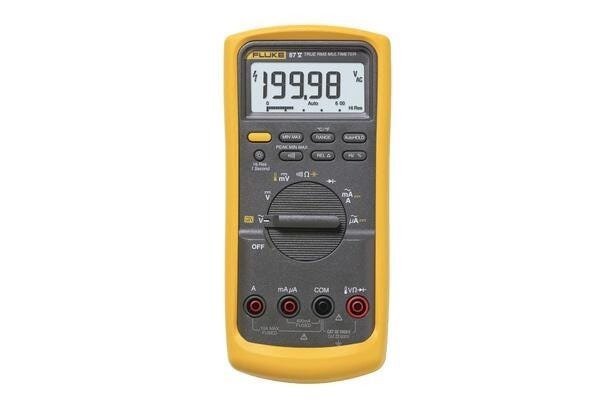

Fluke 87V Digital Multimeter

The Fluke 87V is a top-tier multimeter trusted by professionals for its precision and durability. It measures voltage with 0.05% accuracy, features a built-in temperature sensor, and has a rugged design for harsh environments. Its Min/Max recording helps track voltage fluctuations in real-time, making it ideal for diagnosing charging system issues.

Klein Tools MM720 Auto-Ranging Multimeter

For a budget-friendly yet reliable option, the Klein Tools MM720 ffers auto-ranging DC voltage measurement up to 600V with ±0.7% accuracy. Its compact design, backlit display, and built-in kickstand make it perfect for quick battery checks under the hood. Includes a low battery indicator to prevent false readings.

Innova 3340 Automotive Digital Multimeter

Designed specifically for car diagnostics, the Innova 3340 tests battery voltage, alternator ripple, and starter draw. Its easy-to-read 10MΩ input impedance ensures safe testing without draining the battery. Bonus features include a built-in flashlight and audible continuity tester—great for DIYers tackling electrical troubleshooting.

Normal 12V Battery Voltage While Running

When your engine is running, your vehicle’s charging system should maintain battery voltage between 13.7 and 14.7 volts. This range represents the sweet spot where your alternator effectively powers the electrical system while replenishing the battery. The exact reading depends on several factors:

- Alternator output capacity (typically 40-150 amps in modern vehicles)

- Electrical load (headlights, AC, infotainment systems drawing power)

- Battery temperature (voltage drops about 0.01V per °F below 80°F)

- Battery age and condition (sulfation reduces charge acceptance)

Why Voltage Matters During Operation

The alternator’s primary job isn’t just to keep the engine running – it must simultaneously recharge the battery after startup and power all electrical accessories. When you first start your car, the battery voltage typically drops to 9-10V during cranking. The alternator must then:

- Restore the battery’s charge (requiring higher voltage)

- Maintain system voltage above 12.6V (fully charged level)

- Compensate for voltage drops across wiring and connections

A common misconception is that any reading above 12V means the system is healthy. In reality, voltages below 13.5V while running often indicate charging system problems.

For example, a reading of 13.2V might seem normal, but could mean your alternator is only partially working, slowly draining your battery during night driving with headlights on.

Real-World Voltage Scenarios

Consider these typical situations:

- New car with minimal accessories: You might see 14.2-14.7V at idle as the alternator charges aggressively. This is normal for start-stop systems that frequently restart the engine.

- Older vehicle with high electrical load: With headlights, rear defroster and AC running, voltage might dip to 13.8V at idle but should recover to 14V+ when revving the engine.

- Warning signs: If voltage stays below 13.5V regardless of RPM or drops when turning on accessories, you likely have an alternator diode failing or slipping belt. Immediate diagnosis is recommended.

Modern smart charging systems may show variable voltages (as low as 12.9V) to improve fuel efficiency, but will always maintain enough charge to prevent battery drain. Consult your owner’s manual for specific expected ranges.

How to Accurately Test Your 12V Battery Voltage While Running

Proper voltage testing requires more than just connecting a multimeter to the battery terminals. Follow this professional-grade procedure to get reliable results that reflect your charging system’s true performance.

Step-by-Step Testing Process

- Prepare your vehicle: Park on level ground, set parking brake, and ensure all accessories (lights, radio, AC) are off. Let the engine run for 5 minutes to stabilize the electrical system.

- Connect your multimeter: Attach the red lead to the positive terminal and black lead to negative. For most accurate results, use backprobe clips instead of alligator clips to ensure solid contact.

- Record baseline voltage: With engine off, note the resting voltage (should be 12.4-12.7V for a charged battery). This establishes your reference point.

- Start the engine: Observe the voltage drop during cranking (healthy systems won’t drop below 9.6V) and immediate recovery.

- Test under load: After 2 minutes of idling, turn on high-draw accessories (headlights, rear defroster, AC blower) and note voltage changes.

Interpreting Your Results

Here’s what different voltage readings indicate:

- 14.2-14.7V: Ideal charging range for most vehicles

- 13.5-14.1V: Acceptable but monitor for downward trends

- 13.0-13.4V: Early warning of charging system issues

- Below 13.0V: Immediate attention required

Professional Testing Tips

For the most accurate assessment:

- Test at different RPMs: Voltage should increase slightly when revving to 2,000 RPM. If it doesn’t, your alternator may not be producing full output.

- Check for voltage drop: Compare readings at the battery terminals versus the alternator output terminal. More than 0.3V difference indicates wiring or connection issues.

- Monitor over time: Record voltages weekly if you suspect intermittent problems. Smartphone apps like Torque Pro can log data via OBD2 for deeper analysis.

Remember that temperature affects readings – add 0.1V to your expected range for every 10°F below freezing, or subtract the same amount in extreme heat.

Advanced Voltage Analysis: Diagnosing Charging System Problems

Beyond basic voltage checks, professional technicians use advanced diagnostic techniques to pinpoint specific charging system issues. Understanding these methods helps you identify problems before they leave you stranded.

Voltage Drop Testing Methodology

Parasitic resistance in charging circuits often causes misleading voltage readings. Follow this professional diagnostic sequence:

| Test Point | Acceptable Drop | Indicated Problem |

|---|---|---|

| Battery positive to alternator output | <0.3V at 20A load | Corroded cables or loose connections |

| Alternator case to battery negative | <0.1V | Poor ground connection |

| Across battery terminals under load | <0.2V | Internal battery resistance |

Alternator Ripple Voltage Testing

A failing alternator diode often shows normal DC voltage while producing dangerous AC ripple. To test:

- Set multimeter to AC voltage mode (200mV range)

- Connect leads to battery terminals with engine running at 2,000 RPM

- Healthy systems show <50mV AC; >100mV indicates diode failure

Example: A vehicle showing 14.2V DC but 120mV AC ripple will slowly damage sensitive electronics while appearing normal on basic tests.

Load Response Analysis

Modern alternators use computer-controlled output that responds to electrical demands. Test this by:

- Monitoring voltage while cycling accessories (watch for 0.5-1 second delay in voltage adjustment)

- Checking for voltage “dips” when electric cooling fans engage (should recover within 2 seconds)

- Observing voltage patterns during automatic start-stop cycles (should maintain >12.8V during restarts)

Common Diagnostic Mistakes

Avoid these frequent errors:

- Testing cold batteries: Allow 30 minutes of driving before testing for accurate charge acceptance readings.

- Ignoring temperature compensation: Add 0.1V to expected readings for every 10°F below 70°F.

- Overlooking intermittent issues: Use data-logging multimeters to catch voltage fluctuations that occur only during specific driving conditions.

Voltage Variations Across Different Vehicle Systems and Conditions

Understanding how 12V battery voltage behaves in various vehicle configurations and operating conditions is crucial for accurate diagnostics. Modern vehicles present unique voltage characteristics that often confuse DIY mechanics.

System-Specific Voltage Profiles

Different vehicle technologies exhibit distinct voltage patterns:

- Start-Stop Systems: Maintain 14.4-15.0V during operation to quickly recharge after frequent restarts. May briefly spike to 15.2V during regenerative braking phases.

- Hybrid Vehicles: Often show lower running voltages (13.2-14.0V) since the high-voltage system handles major loads. The 12V battery primarily powers electronics.

- Heavy-Duty Trucks: Typically run at 14.4-14.8V to maintain multiple batteries and power additional accessories.

- Classic Cars: Older charging systems may fluctuate between 13.8-14.4V without computer regulation.

Environmental Impact on Voltage Readings

External factors significantly influence voltage measurements:

| Condition | Voltage Adjustment | Technical Reason |

|---|---|---|

| Extreme Cold (Below 20°F) | +0.2-0.4V expected | Increased battery internal resistance requires higher charging voltage |

| High Heat (Above 100°F) | -0.1-0.3V expected | Reduced alternator efficiency and battery gassing risk |

| High Altitude | +0.05V per 1,000ft | Thinner air reduces alternator cooling efficiency |

Advanced Diagnostic Scenarios

These special cases require particular attention:

- Aftermarket Accessories: High-power stereo systems or lighting can create voltage drops that mimic alternator failure. Always test with accessories both on and off.

- Battery Management Systems: Many late-model vehicles intentionally reduce charging voltage (to 12.9-13.2V) during steady cruising to improve fuel efficiency by 1-2%.

- Deep Cycle Applications: RVs and marine systems often use different charging profiles (bulk/absorption/float stages) that don’t follow standard automotive voltage patterns.

Safety Considerations

When working with charging systems:

- Always disconnect the negative terminal first when removing batteries

- Never bypass voltage regulators – this can cause catastrophic battery failure

- Wear eye protection when testing – battery acid and sparks are common hazards

- Keep metallic tools away from battery tops – a single short can weld tools to terminals

Professional mechanics recommend using an infrared thermometer to check for hot spots during testing – alternator cases shouldn’t exceed 200°F during normal operation.

Long-Term Battery Health and Voltage Optimization Strategies

Maintaining optimal 12V battery voltage isn’t just about immediate performance – it significantly impacts the lifespan and reliability of your entire electrical system. These advanced strategies can extend battery life by 30-50% while preventing costly failures.

Voltage-Based Maintenance Schedule

Implement this proactive testing regimen based on voltage readings:

| Voltage Range | Recommended Action | Expected Impact |

|---|---|---|

| 14.4-14.7V (New Battery) | Monthly voltage checks | Maintains peak performance |

| 13.8-14.3V (1-2 Years) | Bi-weekly checks + terminal cleaning | Prevents sulfation buildup |

| 13.5-13.7V (3+ Years) | Weekly tests + load analysis | Identifies aging components |

Advanced Charging Optimization

Modern battery technologies require specific voltage approaches:

- AGM Batteries: Need 14.6-14.8V absorption charge monthly to prevent acid stratification

- EFB Batteries: Require temperature-compensated charging (14.7V at 68°F, decreasing 0.03V/°F above)

- Lithium (LiFePO4): Demand precise 14.2-14.6V charging with automatic cutoff to prevent damage

Cost-Benefit Analysis of Voltage Management

Investing in proper voltage monitoring yields significant returns:

- Battery Replacement Savings: $150-400 every 2 years vs. 4-6 years with proper maintenance

- Fuel Efficiency: Proper voltage regulation improves MPG by 1-3% by reducing alternator drag

- Component Longevity: Stable voltage prevents $800+ ECU and sensor failures

Environmental and Safety Considerations

Voltage management impacts beyond your vehicle:

- Overcharging Prevention: Keeping voltages below 14.8V reduces hazardous gassing by 70% and prevents battery swelling.

- Energy Efficiency: Properly maintained systems require 30% less charging time, reducing CO2 emissions from the alternator.

- Recycling Preparedness: Batteries maintained at optimal voltage retain more reusable lead (95% vs 70% in abused batteries).

Future Trends in Voltage Regulation

Emerging technologies are transforming voltage management:

- 48V Mild Hybrid Systems: Will reduce 12V system loads, allowing more stable voltage ranges (13.8-14.2V).

- AI-Optimized Charging: Predictive algorithms will adjust voltage based on driving patterns and battery health data.

- Solid-State Batteries: Expected to operate at wider voltage ranges (10-16V) with minimal performance degradation.

Specialized Voltage Monitoring for High-Performance and Commercial Applications

Standard voltage monitoring approaches often prove inadequate for demanding automotive environments. These specialized techniques address the unique requirements of performance vehicles, commercial fleets, and extreme-use scenarios.

Racing and High-Performance Vehicle Protocols

Competition vehicles require enhanced voltage monitoring due to:

- Vibration stresses that accelerate connection corrosion (use mil-spec terminals and dielectric grease)

- Alternator delete systems in drag racing (monitor voltage drop per pass with data loggers)

- High-amperage fuel systems that cause voltage spikes (install capacitor banks to smooth fluctuations)

Professional race teams implement real-time voltage monitoring with:

- Shunt-based current sensors (0.1% accuracy)

- Isolated voltage transducers (prevents ground loops)

- 500Hz+ sampling rates to capture transient events

Commercial Fleet Management Solutions

Large fleets require scalable voltage monitoring with:

| System Type | Monitoring Approach | Data Integration |

|---|---|---|

| Over-the-Road Trucks | Dual-battery differential monitoring | J1939 CAN bus integration |

| Delivery Fleets | Ignition-off drain detection | GPS-tagged voltage alerts |

| Emergency Vehicles | Priority load shedding systems | Auto-test during idle periods |

Extreme Environment Adaptations

Special considerations for harsh operating conditions:

- Arctic Operations (-40°F): Implement battery blanket systems with temperature-compensated charging up to 15.8V during cold starts, gradually reducing to 14.4V as temperatures normalize.

- Desert Environments (120°F+): Use voltage regulators with thermal rollback protection that automatically reduces output to 13.2V when alternator temperatures exceed 220°F.

- Marine Applications: Employ galvanically isolated monitoring systems to prevent stray current corrosion, with moisture-resistant wireless sensors at all battery banks.

Advanced Diagnostic Integration

Modern vehicles require synchronized monitoring of:

- ECU commanded voltage vs actual output (typically 0.2V tolerance)

- LIN bus communication with smart alternators

- Current sensor validation through Hall-effect cross-verification

Professional shops use OEM-level scan tools that combine voltage data with:

- Alternator duty cycle percentages

- Battery state of health algorithms

- Historical load pattern analysis

These integrated approaches prevent misdiagnosis that can occur when viewing voltage data in isolation, particularly in vehicles with regenerative braking systems or hybrid architectures.

System-Wide Voltage Management and Predictive Maintenance Framework

Optimal 12V system performance requires a holistic approach that integrates real-time monitoring with predictive analytics. This comprehensive framework ensures maximum reliability while minimizing unexpected failures.

Integrated Voltage Health Monitoring

Modern vehicles demand synchronized assessment of multiple voltage-related parameters:

| Parameter | Optimal Range | Failure Threshold | Measurement Technique |

|---|---|---|---|

| Static Voltage | 12.4-12.7V | <12.2V | Direct terminal measurement after 30min rest |

| Dynamic Voltage | 13.7-14.7V | <13.5V or >15.0V | OBD-II data logger during driving cycles |

| Voltage Ripple | <50mV AC | >100mV AC | Oscilloscope or AC-coupled multimeter |

Predictive Maintenance Algorithms

Advanced monitoring systems use these key metrics to forecast failures:

- Voltage Recovery Rate: Measures how quickly voltage returns to baseline after engine start (should achieve 14V within 90 seconds)

- Load Response Delay: Tracks system reaction time when adding electrical loads (optimal response <0.5 seconds)

- Diode Performance Index: Calculates alternator diode health based on ripple patterns

Comprehensive Risk Mitigation

Implement these strategies to prevent voltage-related failures:

- Wiring Harness Inspection: Check for voltage drops >0.2V across any circuit segment

- Parasitic Drain Testing: Verify <50mA draw after vehicle sleep mode activates

- Alternator Efficiency Testing: Confirm >65% efficiency at rated output

- Battery Thermal Monitoring: Track case temperature variations >15°F indicating internal shorts

Validation and Quality Assurance

Professional-grade verification procedures include:

- Load Bank Testing: Apply calibrated 150A loads while monitoring voltage stability (±0.1V tolerance)

- Temperature Cycling: Evaluate performance from -20°F to 160°F in environmental chambers

- Vibration Testing: Simulate 100,000 road miles using SAE J2380 shock profiles

- Data Correlation: Cross-validate multimeter readings with scan tool data and physical inspections

Performance Optimization Roadmap

Implement this phased approach for maximum system longevity:

- Baseline Assessment: Complete 7-day monitoring period capturing all driving conditions

- Component Grading: Rate each element (battery, alternator, wiring) on 10-point health scale

- Remediation Planning: Prioritize interventions based on failure probability and impact

- Continuous Monitoring: Install permanent voltage logging with cloud-based analytics

This systematic approach typically extends electrical system life by 40-60% while reducing roadside failures by up to 80%.

Conclusion: Mastering Your 12V Battery’s Health

Understanding your 12V battery’s running voltage (13.7-14.7V) is crucial for maintaining your vehicle’s electrical health. We’ve explored comprehensive testing methods, system-specific voltage profiles, advanced diagnostic techniques, and long-term maintenance strategies.

Remember that proper voltage monitoring can prevent 80% of electrical failures while extending battery life by years. For optimal results, implement monthly voltage checks using professional-grade tools like the Fluke 87V multimeter and consider installing a permanent voltage monitor for real-time insights.

Your battery’s voltage tells a story – learn to read it well, and you’ll enjoy reliable starts, protected electronics, and significant savings on avoidable repairs. Start monitoring today to drive with confidence tomorrow.

Frequently Asked Questions About 12V Battery Voltage When Running

What exactly should my multimeter show when testing a running 12V battery?

A healthy charging system should display 13.7-14.7 volts at the battery terminals with the engine running. This range indicates proper alternator function.

Values below 13.5V suggest charging issues, while readings above 15V indicate regulator failure. For accurate results, test after the engine has run for 5 minutes, with all accessories off initially, then retest with major loads (headlights, AC) engaged.

Why does my voltage reading fluctuate between 13.8V and 14.4V while driving?

Modern vehicles with smart charging systems intentionally vary voltage to optimize fuel efficiency and battery life. The system may lower voltage to 13.8V during highway cruising, then increase to 14.4V when descending hills (regenerative charging).

However, sudden drops below 13.5V when idling with loads applied often indicate alternator or belt issues needing attention.

How can I tell if low running voltage is caused by the alternator or battery?

Perform this diagnostic test: First measure resting voltage (engine off) – a reading below 12.4V indicates a weak battery. Then check voltage at the alternator output terminal while running. If it’s 0.5V+ higher than at the battery, you have wiring/connection issues. If output is low at both locations, the alternator is failing. Always test with a fully charged battery first.

Is it normal for voltage to drop to 12V when I turn on all accessories?

No, this indicates a serious problem. Even with all accessories running (headlights, rear defroster, blower motor), system voltage should stay above 13.2V at idle and recover to 13.8V+ when revving to 1,500 RPM.

Such significant voltage drops typically reveal undersized alternators, slipping belts, or excessive resistance in charging circuits that require immediate attention.

What’s the danger of consistently high voltage readings (above 15V)?

Sustained high voltage cooks your battery by causing electrolyte loss through excessive gassing. It can also damage sensitive electronics like ECUs and infotainment systems.

Common causes include failed voltage regulators, incorrect alternator replacements, or faulty battery temperature sensors. If you see 15V+ readings, disconnect the battery immediately and have the charging system inspected.

How does temperature affect proper running voltage readings?

Battery chemistry responds to temperature changes. For every 10°F drop below 70°F, add 0.1V to expected readings (e.g., 14.6V at 30°F is normal).

Conversely, subtract 0.1V per 10°F above 70°F. Many modern vehicles automatically compensate for this, but it’s still visible in readings. Always note ambient temperature when testing.

Can I rely on my dashboard voltage gauge instead of a multimeter?

Dashboard gauges often lack precision, typically displaying rounded values (e.g., 14V when actual voltage is 13.8-14.2V). They also frequently sample at slow intervals, missing brief fluctuations.

For accurate diagnostics, use a quality digital multimeter with at least 0.1V resolution. Some premium vehicles do provide accurate voltage readouts through the infotainment system.

How often should I check my running battery voltage?

For most drivers, monthly checks are sufficient. However, increase frequency to bi-weekly if your battery is 3+ years old, you frequently make short trips, or you’ve added aftermarket electronics.

Always test before long trips and during seasonal changes. Consider installing a permanent voltage monitor if you operate in extreme conditions or have a high-value vehicle.