Disclosure

This website is a participant in the Amazon Services LLC Associates Program,

an affiliate advertising program designed to provide a means for us to earn fees

by linking to Amazon.com and affiliated sites.

A fully charged 6V golf cart battery should read 6.37 to 6.42 volts—but most owners don’t realize this critical detail. You might assume a simple 6.0V reading means your battery is ready, but the truth is more nuanced.

Voltage fluctuations, temperature, and charging methods dramatically impact accuracy. Without this knowledge, you risk undercharging (killing battery lifespan) or overcharging (causing dangerous overheating).

Best Tools for Measuring 6V Golf Cart Battery Voltage

Fluke 115 Digital Multimeter

The Fluke 115 is a top-tier multimeter for golf cart batteries, offering 0.5% accuracy on DC voltage readings. Its rugged design, auto-ranging feature, and easy-to-read display make it perfect for checking 6V battery health. Trusted by professionals, it ensures precise measurements every time.

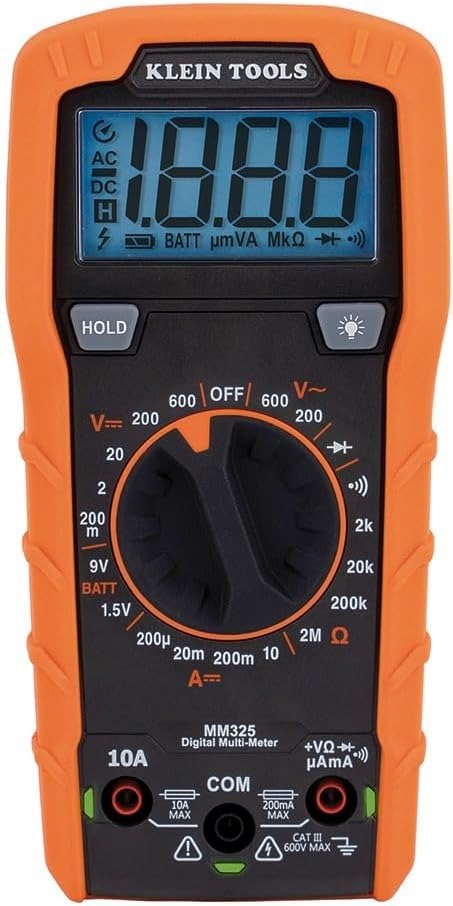

Klein Tools MM325 Multimeter

For a budget-friendly yet reliable option, the Klein Tools MM325 delivers accurate voltage readings with a CAT III 600V safety rating. Its compact design, durable construction, and straightforward interface make it ideal for golfers who need quick, dependable battery checks without complexity.

NOCO Genius 5 Battery Charger

The NOCO Genius 5 isn’t just a multimeter—it’s a smart charger that maintains and diagnoses 6V batteries. With automatic voltage detection, desulfation mode, and a built-in voltage meter, it ensures your golf cart battery stays fully charged and healthy for longer.

The Ideal Voltage Range for a 6V Golf Cart Battery

Why 6.37V to 6.42V is the Gold Standard

A fully charged 6V golf cart battery should measure between 6.37 and 6.42 volts at rest (after sitting for 12+ hours post-charging). This range accounts for the battery’s chemical composition—lead-acid cells generate ~2.12V each, and three cells in series produce ~6.37V when stabilized. Many golfers mistakenly expect exactly 6.0V, but this lower reading often indicates a partial charge or aging battery.

Factors That Influence Voltage Readings

Several variables can cause fluctuations in your measurements:

- Temperature: Voltage drops in cold weather (e.g., 6.30V at 50°F) and rises in heat (e.g., 6.45V at 90°F). Always check ambient conditions.

- Surface charge: Immediately after charging, readings may show 6.5V+ due to residual energy. Wait 12 hours for accurate results.

- Load testing: Voltage under load (e.g., while driving) will be lower—healthy batteries maintain ≥5.8V under moderate strain.

Real-World Voltage Scenarios and What They Mean

Here’s how to interpret common readings:

- Below 6.2V: Indicates undercharging or sulfation (crystal buildup on plates). Use a desulfating charger like the NOCO Genius G3500.

- 6.0V flat: Often seen in batteries at 50% charge. Prolonged operation at this level accelerates plate degradation.

- Above 6.5V: Suggests overcharging, which warps plates and boils off electrolyte. Verify your charger’s output matches battery specs.

Pro Tip: How to Measure Voltage Correctly

For reliable results:

- Use a calibrated multimeter (like the Fluke 115) set to DC voltage.

- Test at the battery terminals—not through corroded cables.

- Check all batteries in a series setup individually. One weak cell (reading <6.3V) can drag down the entire pack.

Example: A 36V golf cart with six 6V batteries should show each battery between 6.37V–6.42V. If one reads 6.1V, it likely needs replacement to prevent system-wide strain.

How to Properly Charge and Maintain Your 6V Golf Cart Battery

The Right Charging Process for Optimal Performance

Charging a 6V golf cart battery correctly is crucial for longevity. Unlike car batteries, deep-cycle golf cart batteries require slow, controlled charging at 10-15% of their amp-hour rating.

For a typical 225Ah battery, this means a 22-25 amp charger. Fast charging generates excessive heat that warps lead plates and reduces battery life by up to 40%.

Step-by-Step Charging Procedure

- Pre-charge inspection: Check electrolyte levels (if applicable) – plates should be covered by ¼” of fluid. Use distilled water only for top-ups.

- Connection sequence: Always connect charger clips to battery terminals before plugging in the charger to prevent dangerous sparks.

- Charging duration: A fully depleted battery needs 8-10 hours. Smart chargers like the NOCO G3500 automatically switch to float mode when done.

- Post-charge protocol: Wait 12 hours before taking voltage readings to allow surface charge to dissipate.

Common Charging Mistakes to Avoid

- Overcharging: Leaving batteries on charge for days causes electrolyte loss. Modern chargers prevent this, but older models require manual monitoring.

- Undercharging: Stopping at 80% charge creates sulfation. Always complete full charge cycles.

- Mixed battery ages: Never charge old and new batteries together – the weaker one will drag down the entire bank.

Maintenance Tips for Maximum Battery Life

Proper care can extend battery life from 3 to 5+ years:

- Monthly equalization: Use a charger’s equalize mode (15.5V for 1-2 hours) to break down sulfate crystals

- Terminal care: Clean corrosion with baking soda paste and apply dielectric grease to prevent future buildup

- Storage protocol: For winter storage, charge to 100%, disconnect cables, and recharge every 60 days

Pro Tip: Track battery health by logging voltage readings before and after charging. A battery that can’t hold above 6.3V after 24 hours needs replacement.

Advanced Troubleshooting for 6V Golf Cart Battery Issues

Diagnosing Voltage Anomalies

When your 6V battery shows abnormal readings, systematic troubleshooting is essential. A voltage reading below 6.2V after proper charging typically indicates one of three issues:

| Voltage Reading | Potential Issue | Diagnostic Test |

|---|---|---|

| 5.8-6.1V | Sulfation buildup | Check specific gravity (should be 1.265-1.285) |

| Fluctuating 5.5-6.3V | Loose cell connection | Conduct resistance test between cells |

| 0V or sudden drops | Shorted cell | Load test each cell individually |

Load Testing Methodology

Proper load testing reveals a battery’s true condition:

- Prepare the battery: Charge fully and let rest for 12 hours

- Apply load: Use a 50-amp load tester for 15 seconds (simulates golf cart hill climb)

- Monitor voltage: Healthy batteries maintain ≥5.8V during test

- Recovery check: Voltage should rebound to ≥6.2V within 5 minutes

Watering and Electrolyte Management

Flooded lead-acid batteries require precise water maintenance:

- Fill timing: Only add distilled water after charging to prevent overflow

- Level precision: Maintain 1/4″ above plates – too low exposes plates, too high causes acid dilution

- Specific gravity: Use a hydrometer monthly – variations >0.05 between cells indicate problems

Reviving Weak Batteries

For batteries showing early failure signs:

- Pulse desulfation: Use a smart charger’s recovery mode for 48-72 hours

- Controlled overcharge: Apply 7.2V for 2 hours (monitor temperature closely)

- Electrolyte replacement: For severely sulfated batteries, replace acid solution (professional only)

Expert Insight: Batteries in a series bank fail progressively – when one weak battery drops below 5.5V under load, it forces others to work harder, accelerating system-wide failure. Always replace the entire set if more than one battery shows >20% capacity variance.

Optimizing Battery Performance in Different Golf Cart Systems

Understanding Series vs. Parallel Configurations

Golf cart battery banks typically use series connections to achieve higher voltage. In a 36V system, six 6V batteries are connected in series (positive to negative).

This configuration multiplies voltage while maintaining the same amp-hour capacity. However, this makes the entire system only as strong as its weakest battery. A single underperforming battery (reading below 6.2V) can reduce range by up to 30% and strain other batteries.

Balancing Multiple Battery Banks

For carts with multiple battery strings (common in large utility vehicles), follow these best practices:

- Voltage matching: All batteries should be within 0.1V of each other before connecting

- Age synchronization: Never mix batteries with more than 6 months age difference

- Connection integrity: Use identical cable lengths and gauge (typically 4AWG or thicker) for all parallel connections

Temperature Compensation Strategies

Battery performance varies dramatically with temperature. For every 10°F change, adjust charging voltage by 0.03V per cell (0.09V for 6V batteries):

| Temperature Range | Charging Voltage Adjustment | Expected Voltage Drop |

|---|---|---|

| Below 50°F | +0.18V (to 6.55V) | 10-15% capacity loss |

| 70-90°F | Standard 6.37V | Normal operation |

| Above 100°F | -0.12V (to 6.25V) | 20% shorter cycle life |

Advanced Monitoring Techniques

Professional golf cart technicians recommend these monitoring approaches:

- Mid-point voltage testing: Measure voltage between batteries 3 and 4 in a 6-battery series – should be exactly half of total pack voltage

- Discharge rate logging: Track voltage drop per mile – healthy systems lose ≤0.2V/mile under normal load

- Infrared scanning: Use thermal imaging to identify hot spots indicating resistance issues

Safety Note: Always wear acid-resistant gloves and eye protection when working with battery banks. Hydrogen gas buildup during charging requires proper ventilation – never charge in enclosed spaces.

Long-Term Battery Economics and Emerging Technologies

Cost Analysis: Flooded vs. AGM vs. Lithium-Ion

When evaluating 6V golf cart battery options, consider both upfront and lifecycle costs:

| Battery Type | Initial Cost | Cycle Life | Maintenance | Total 5-Year Cost |

|---|---|---|---|---|

| Flooded Lead-Acid | $100-$150 | 500-800 cycles | High (watering, cleaning) | $1,200-$1,800 |

| AGM | $200-$300 | 700-1,000 cycles | Minimal | $900-$1,400 |

| Lithium-Ion | $600-$900 | 2,000-3,000 cycles | None | $600-$900 |

While lithium batteries have 3x higher initial cost, their 5x longer lifespan and zero maintenance often make them more economical long-term. AGM batteries offer a middle ground with better performance than flooded but at a 40% premium.

Environmental Impact and Recycling

Proper battery disposal is crucial:

- Lead-acid batteries are 99% recyclable – core deposits often cover recycling fees

- Lithium batteries require special handling – many manufacturers offer take-back programs

- Illegal disposal of lead batteries carries fines up to $10,000 per incident

The Future of Golf Cart Power Systems

Emerging technologies are transforming golf cart power:

- Smart BMS integration: New lithium systems include Bluetooth monitoring that tracks individual cell health in real-time

- Solar charging: Roof-mounted 100W panels can extend range by 15-20% in sunny climates

- Fast-charging stations: Commercial courses are adopting 30-minute charging systems with automatic watering

Safety Evolution in Battery Technology

Modern safety features include:

- Thermal runaway protection in lithium batteries

- Spill-proof AGM designs for safer operation on slopes

- Automatic watering systems that eliminate manual acid exposure

Pro Tip: When upgrading battery technology, ensure your charger is compatible. Using a lead-acid charger on lithium batteries can be dangerous and voids warranties. Many modern chargers now feature selectable battery chemistry modes.

Advanced System Integration and Performance Optimization

Battery-to-Motor Efficiency Optimization

Maximizing golf cart performance requires understanding the electrical relationship between batteries and motor. A typical 36V system with six 6V batteries should deliver optimal performance when:

- Voltage sag under full load stays above 32V (no more than 11% drop)

- Current draw remains below 75% of battery bank’s maximum discharge rate

- Recovery time after heavy load is under 2 minutes to 90% voltage restoration

Controller Programming for Battery Longevity

Modern golf cart controllers offer programmable settings that significantly impact battery life:

| Parameter | Recommended Setting | Impact on Batteries |

|---|---|---|

| Acceleration Rate | Medium (3-4 sec 0-15mph) | Reduces peak current draw by 30-40% |

| Regen Braking | 15-20% strength | Adds 5-8% charge without overvoltage risk |

| Low Voltage Cutoff | 31.5V (for 36V system) | Prevents deep discharge damage |

Wiring and Connection Best Practices

Proper electrical infrastructure is crucial for system efficiency:

- Cable sizing: Use 4AWG for runs under 10ft, 2AWG for longer distances – reduces voltage drop by up to 1.5V

- Terminal preparation: Clean with wire brush and apply antioxidant gel – reduces resistance by 0.002Ω per connection

- Routing: Keep battery cables separated from motor cables to prevent electromagnetic interference

Performance Monitoring Systems

Advanced monitoring solutions provide real-time diagnostics:

- Shunt-based monitors: Track amp-hours consumed with 99% accuracy

- Bluetooth battery monitors: Provide cell-by-cell voltage readings via smartphone

- Historical logging: Identifies gradual performance degradation patterns

Pro Tip: For carts used in hilly terrain, consider installing an auxiliary battery bank with automatic transfer switch. This allows isolating the primary bank during steep climbs, reducing depth-of-discharge by up to 50% on challenging routes.

Professional-Grade Battery Management and System Validation

Comprehensive Battery Health Assessment Protocol

For commercial operations or serious enthusiasts, implementing a professional battery assessment routine ensures peak performance:

| Test Type | Frequency | Acceptable Parameters | Corrective Actions |

|---|---|---|---|

| Static Voltage Test | Weekly | 6.35-6.42V per battery | Equalize charge if variance >0.05V |

| Dynamic Load Test | Monthly | <5% voltage drop under 50A load | Check connections/cables if exceeded |

| Capacity Test | Quarterly | >90% rated Ah capacity | Desulfation or replacement if below |

Advanced Charging Cycle Optimization

Professional charging strategies extend battery life beyond standard practices:

- Pulse charging: Intermittent high-frequency pulses (every 15 minutes) break down sulfate crystals without overheating

- Temperature-compensated charging: Automatic voltage adjustment (0.003V/°F/cell) maintains ideal absorption rates

- Capacity-based termination: Smart chargers that stop when return current drops below 1% of rated capacity

System-Wide Performance Validation

Comprehensive testing should evaluate:

- Voltage consistency: Maximum 0.1V difference between any two batteries under load

- Energy efficiency: At least 85% of stored energy converted to mechanical work

- Thermal performance: Battery temperature rise <15°F during continuous operation

Risk Mitigation Strategies

Professional installations incorporate multiple safeguards:

- Automatic watering systems: Maintain perfect electrolyte levels with float valves

- Hydrogen venting: Explosion-proof fans activated at 1% H2 concentration

- Corrosion prevention: Vapor-phase corrosion inhibitors in battery compartments

Expert Recommendation: Implement a battery rotation schedule for multi-cart fleets – cycling batteries between different carts every 3 months equalizes wear patterns and can extend average lifespan by 18-22%. Document all maintenance in a log tracking voltage trends, water usage, and cleaning frequency for predictive maintenance.

Conclusion

Understanding your 6V golf cart battery’s proper voltage range (6.37-6.42V at rest) is fundamental to maximizing performance and lifespan. Throughout this guide, we’ve explored essential maintenance techniques, advanced troubleshooting methods, system optimization strategies, and professional-grade management protocols.

From proper charging procedures to temperature compensation and load testing, each factor plays a critical role in your battery’s health. Remember that consistent monitoring and preventive care can double your battery’s service life compared to reactive maintenance.

Whether you’re a casual golfer or fleet manager, implementing these best practices will ensure reliable power and significant cost savings. Start applying these techniques today to keep your golf cart running at peak performance for years to come.

Frequently Asked Questions About 6V Golf Cart Batteries

What exactly does a 6V golf cart battery measure when fully charged?

A properly charged 6V golf cart battery should measure 6.37 to 6.42 volts at rest (after sitting 12+ hours post-charging). This accounts for lead-acid chemistry where each cell produces ~2.12V.

Immediately after charging, you might see 6.5V+ due to surface charge, which dissipates over time. Always measure voltage when the battery is cool and hasn’t been recently charged or discharged for accurate readings.

How often should I check my golf cart battery voltage?

For optimal maintenance:

- Weekly checks during active season

- Monthly checks during storage

- Before/after charging to monitor system health

Use a quality multimeter (like Fluke 115) and log readings to track performance trends. Significant voltage drops between checks indicate developing problems.

Why does my new 6V battery only show 6.3V after charging?

This typically indicates either:

- The battery wasn’t fully charged (some chargers stop at 90%)

- It needs conditioning (new batteries often require 3-5 full cycles)

- Your charger’s output is insufficient (verify it matches battery specs)

Try a 12-hour equalization charge at 7.2V if the issue persists after 5 cycles.

Can I mix old and new 6V batteries in my golf cart?

Never mix batteries with more than 6 months age difference. Older batteries act as resistors, forcing new ones to work harder.

This can reduce new battery lifespan by 40-60%. Always replace the entire set, and consider upgrading to lithium if replacing multiple flooded batteries becomes costly.

How do temperature changes affect my 6V battery readings?

Temperature significantly impacts voltage:

| Temperature | Voltage Adjustment |

|---|---|

| Below 50°F | Subtract 0.1V from reading |

| Above 90°F | Add 0.08V to reading |

Always store batteries in climate-controlled spaces when possible.

What’s the safest way to test battery voltage while driving?

Install a permanent voltage meter with these features:

- Waterproof display (mounted on dash)

- 30-second averaging to filter fluctuations

- Programmable low-voltage alarm (set to 5.8V for 6V batteries)

Never use handheld meters while operating the cart – it’s dangerous and gives inaccurate readings due to movement.

How much voltage drop during use is normal?

Under typical golf cart loads (20-30A):

- New battery: 5.9-6.1V is acceptable

- Older battery: 5.7-5.9V indicates 60-70% capacity

- Below 5.5V: Immediate replacement needed

Measure during hill climbs for worst-case scenario testing.

Why does my battery show good voltage but dies quickly?

This “voltage lie” phenomenon occurs when:

- Sulfation creates surface charge that masks capacity loss

- Plate corrosion increases internal resistance

- One weak cell drags down overall performance

Perform a capacity test by timing how long the battery can maintain 5.5V under 25A load – should last 90+ minutes for a healthy 225Ah battery.