Disclosure

This website is a participant in the Amazon Services LLC Associates Program,

an affiliate advertising program designed to provide a means for us to earn fees

by linking to Amazon.com and affiliated sites.

Your car battery contains sulfuric acid, a highly corrosive and dangerous chemical. This powerful electrolyte is essential for generating electricity, but mishandling it can be hazardous.

Many assume car batteries are just simple power boxes, but their chemistry is complex. Sulfuric acid reacts with lead plates to produce the energy your vehicle needs.

Best Battery Testers and Maintenance Tools for Car Batteries

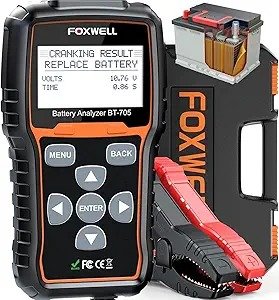

FOXWELL BT705 12V Battery Tester

The FOXWELL BT705 is a top-tier battery analyzer that checks voltage, cold cranking amps (CCA), and overall health. Its color LCD screen and intuitive interface make it easy for beginners and professionals to diagnose battery issues accurately.

NOCO GENIUS5 5-Amp Smart Charger

The NOCO GENIUS5 is a reliable smart charger that safely maintains and revives lead-acid batteries, including AGM and gel types. Its spark-proof technology and automatic voltage detection ensure safe, efficient charging without overcharging risks.

Schumacher SC1281 Battery Charger & Engine Starter

This Schumacher SC1281 is a powerful 30-amp charger with a 100-amp engine start function, perfect for dead batteries. Its microprocessor-controlled system adjusts charging rates automatically, making it ideal for emergency jump-starts and long-term maintenance.

How Sulfuric Acid Powers Your Car Battery

Sulfuric acid (H₂SO₄) is the lifeblood of your car battery, enabling the chemical reactions that generate electricity. Inside a typical lead-acid battery, it serves as the electrolyte—a conductive solution that facilitates ion movement between the battery’s lead plates. When fully charged, the acid concentration is about 35-40%, creating an optimal environment for energy production.

The Chemical Reaction Behind Battery Power

Your battery works through a reversible reaction between sulfuric acid and lead plates:

- Discharging: When you start your car, sulfuric acid reacts with lead (Pb) and lead dioxide (PbO₂) to form lead sulfate (PbSO₄) and release electrons, producing electricity.

- Charging: The alternator reverses this process, converting lead sulfate back into lead, lead dioxide, and sulfuric acid.

This cycle repeats thousands of times, but over time, sulfate crystals can harden (sulfation), reducing battery efficiency.

Why Sulfuric Acid Concentration Matters

A battery’s performance depends on the acid’s specific gravity (density relative to water). A fully charged battery measures ~1.265 SG, while a discharged one drops to ~1.120 SG. Tools like hydrometers or refractometers help monitor this. Low levels indicate:

- Excessive water loss from overcharging

- Plate sulfation due to undercharging

- Internal leaks or damage

For example, if your battery struggles in cold weather, weak acid concentration may be the culprit—thicker sulfate layers resist chemical reactions.

Safety Risks and Handling Tips

Sulfuric acid is highly corrosive and can cause severe burns. Always:

- Wear acid-resistant gloves and goggles

- Work in a ventilated area—charging batteries release explosive hydrogen gas

- Neutralize spills with baking soda (a base)

Myth: “Topping off with acid boosts performance.” In reality, only distilled water should be added—evaporation removes water, not acid. Adding more acid disrupts the electrolyte balance.

How to Safely Check and Maintain Your Battery’s Acid Levels

Regular maintenance of your battery’s electrolyte levels is crucial for longevity and performance. Unlike sealed batteries, traditional lead-acid batteries require periodic checks to ensure proper acid concentration and volume. Here’s how to do it safely and effectively.

Step-by-Step: Testing Electrolyte Levels

Tools You’ll Need:

- Hydrometer or refractometer (for specific gravity testing)

- Distilled water (never tap water)

- Baking soda solution (for spill neutralization)

- Safety goggles and acid-resistant gloves

Procedure:

- Safety First: Park on level ground, turn off the engine, and let the battery cool for 30 minutes—hot batteries can release dangerous gases.

- Visual Inspection: Check each cell’s fluid level through the translucent case. Proper levels should cover plates by ¼-½ inch (6-13mm).

- Specific Gravity Test:

- Insert the hydrometer into a cell and squeeze the bulb to draw in electrolyte

- Release slowly until the float stabilizes

- Read the specific gravity at the fluid line (1.265 = fully charged)

Pro Tip: Test all cells—variations over 0.050 between cells indicate potential damage or uneven charging.

When and How to Add Distilled Water

Only replenish with distilled water when levels are low—never add acid unless the battery was fully drained and professionally serviced. Here’s why:

- During normal operation, only water evaporates from the electrolyte

- Adding acid increases concentration, accelerating plate corrosion

- Overfilling dilutes the electrolyte, reducing cranking power

Fill to just below the split ring inside each cell, leaving room for expansion during charging. After adding water, charge the battery fully to ensure proper mixing.

Troubleshooting Common Acid-Related Issues

- Problem: Rapid water loss in multiple cells

Likely Cause: Overcharging from a faulty voltage regulator (check alternator output at 14.4V max) - Problem: One cell consistently lower than others

Likely Cause: Internal short circuit or physical damage—time for battery replacement - Problem: White/blue crust on terminals

Solution: Sulfuric acid vapor corrosion—clean with baking soda paste and apply anti-corrosion grease

Advanced Battery Acid Maintenance and Reconditioning Techniques

When standard maintenance isn’t enough, these professional-grade techniques can restore performance to aging batteries. Understanding these methods requires knowledge of electrochemistry, but we’ll break it down into practical steps.

Desulfation: Reviving Sulfated Batteries

Sulfation occurs when lead sulfate crystals harden on plates, reducing capacity. There are three proven desulfation methods:

| Method | How It Works | Best For |

|---|---|---|

| Pulse Charging | High-frequency pulses break sulfate crystals without overheating | Mild sulfation (batteries under 2 years old) |

| Chemical Additives | EDTA solutions dissolve sulfate deposits chemically | Batteries with visible sulfate buildup |

| Controlled Overcharge | 14.8V charge for 8-12 hours with temperature monitoring | Professional use only (risk of explosion) |

Safety Note: Always wear face shields for desulfation – the process releases hydrogen sulfide gas (recognizable by its rotten egg smell).

Electrolyte Replacement Procedures

Complete acid replacement should only be done when:

- Specific gravity remains below 1.225 after full charging

- Multiple cells show contamination (brown/black electrolyte)

- Battery is less than 4 years old (otherwise replacement is better)

Step-by-Step Acid Replacement:

- Fully charge battery to suspend all lead sulfate in solution

- Use a battery siphon to remove old acid into proper containment

- Rinse cells 3x with distilled water (never tap water)

- Fill with fresh 35% sulfuric acid solution (1.265 SG)

- Slow charge at 2 amps for 24 hours to stabilize chemistry

Pro Tip: The first charge after replacement is critical – monitor temperature closely and stop if it exceeds 125°F (52°C).

Precision Acid Mixing for Optimal Performance

When preparing electrolyte solutions:

- Always add acid to water (never water to acid) to prevent violent reactions

- Use borosilicate glass or HDPE containers – other plastics may degrade

- Mix in a 3:1 water-to-acid ratio by volume for 35% concentration

- Allow 4 hours cooling period before use – mixing generates significant heat

For cold climates (below -20°F/-29°C), a 38% solution (1.285 SG) provides better freeze protection, but reduces overall battery life by about 15%.

These advanced techniques can extend battery life by 12-18 months when performed correctly. However, improper application can be dangerous – when in doubt, consult a professional battery technician.

Special Considerations for Different Battery Types and Environments

Not all lead-acid batteries are created equal, and environmental factors significantly impact acid performance. Understanding these variations ensures optimal maintenance for your specific battery type and climate conditions.

Comparing Acid Requirements Across Battery Types

While all lead-acid batteries use sulfuric acid, concentration and maintenance needs vary:

- Flooded (Wet Cell) Batteries:

- Require regular water additions (distilled only)

- Optimal acid concentration: 35-38% (1.265-1.285 SG)

- Need quarterly electrolyte checks

- AGM (Absorbent Glass Mat) Batteries:

- Use immobilized electrolyte (no free liquid)

- Higher concentration: 38-40% (1.290-1.300 SG)

- Never open – permanently sealed design

- Gel Cell Batteries:

- Silica-thickened electrolyte

- Lower concentration: 32-35% (1.240-1.260 SG)

- Extremely sensitive to overcharging

Critical Note: Using the wrong charger for AGM or Gel batteries can permanently damage the electrolyte matrix by causing gas pockets or silica fractures.

Climate-Specific Acid Maintenance Strategies

Environmental temperature dramatically affects acid behavior:

| Climate | Acid Adjustment | Maintenance Frequency |

|---|---|---|

| Hot (>90°F/32°C) | Reduce to 33-35% (1.240-1.265 SG) | Monthly checks (evaporates faster) |

| Moderate (32-90°F/0-32°C) | Standard 35-38% (1.265-1.285 SG) | Quarterly checks |

| Cold (<32°F/0°C) | Increase to 38-40% (1.285-1.300 SG) | Pre-winter and mid-winter checks |

Extreme Cold Pro Tip: In arctic conditions, insulate batteries while maintaining ventilation – this prevents electrolyte freezing (which occurs at -92°F/-69°C for 40% acid) while allowing proper gas escape.

Industrial vs. Automotive Battery Acid Differences

Commercial applications often use modified electrolyte formulas:

- Deep Cycle Marine Batteries:

- Contain buffering agents to reduce stratification

- Often use purer sulfuric acid (99.9% vs automotive 93-95%)

- Forklift Batteries:

- May include potassium sulfate additives

- Higher water consumption requires weekly checks

- Solar Storage Batteries:

- Frequently use low-antimony alloys

- Require lower SG (1.225-1.245) for partial state of charge operation

Safety Reminder: Industrial battery acid often contains higher purity sulfuric acid with fewer impurities, making it even more corrosive than automotive-grade electrolyte. Always use chemical-resistant PPE when handling.

The Economics and Environmental Impact of Battery Acid Management

Proper sulfuric acid maintenance affects more than just battery performance—it has significant financial and ecological implications. Understanding these dimensions helps make informed decisions about battery care and replacement.

Cost Analysis: Maintenance vs. Replacement

Implementing proper acid maintenance extends battery life dramatically:

| Maintenance Level | Average Lifespan | 5-Year Cost (2 batteries) | Environmental Impact |

|---|---|---|---|

| No Maintenance | 2-3 years | $300-$450 | 3.5kg lead waste |

| Basic Maintenance | 4-5 years | $150-$225 | 1.75kg lead waste |

| Advanced Maintenance | 6-8 years | $75-$112 | 0.88kg lead waste |

Key Insight: Investing $20 annually in distilled water and testing supplies can save $200+ per battery cycle while reducing environmental impact by 60-75%.

Proper Acid Disposal and Recycling Protocols

Sulfuric acid disposal requires careful handling due to its hazardous nature:

- Neutralization:

- Use 1lb baking soda per gallon of acid

- Add acid to neutralizing solution slowly

- Test pH with litmus paper (aim for 6-8)

- Recycling Options:

- 95% of battery acid is recyclable into new electrolyte

- EPA-certified processors recover 99.9% pure sulfuric acid

- Many auto parts stores accept old batteries/acid free

Safety Alert: Never mix battery acid with other chemicals—even small amounts of chlorine (bleach) create deadly chlorine gas.

Emerging Trends in Battery Acid Technology

The industry is evolving to address environmental and performance challenges:

- Organic Acid Additives: Citric and ascorbic acids that reduce sulfation while being biodegradable

- Nano-Enhanced Electrolytes: Silicon dioxide nanoparticles that improve conductivity at lower concentrations

- Closed-Loop Systems: Batteries with acid reclamation systems that reduce maintenance needs

- Biodegradable Separators: Cellulose-based materials that decompose safely if improperly disposed

Future Outlook: By 2030, new electrolyte formulations may extend battery life to 10+ years while reducing acid toxicity by 40%. Current maintenance practices will need adaptation as these technologies emerge.

Optimizing Battery Acid Performance for Specialized Applications

Different vehicle systems and usage patterns demand tailored approaches to battery acid management. These advanced techniques ensure peak performance for demanding applications while maximizing battery longevity.

High-Performance and Racing Applications

Competition vehicles require modified electrolyte strategies:

- Acid Concentration Adjustments:

- Short-duration races: 40-42% concentration (1.300-1.320 SG) for maximum current

- Endurance events: 33-35% concentration (1.240-1.265 SG) for better heat dissipation

- Custom Electrolyte Additives:

- Phosphoric acid (0.5% by volume) reduces internal resistance

- Sodium sulfate (1% solution) improves cold cranking performance

- Never mix additives – create unstable chemical reactions

Pro Tip: Race batteries should have electrolyte levels checked after every event – vibration causes accelerated water loss. Use safety-wired caps to prevent acid spills during competition.

Commercial Fleet Maintenance Protocols

Large vehicle fleets require systematic acid management:

| Vehicle Type | Check Frequency | Optimal SG Range | Special Considerations |

|---|---|---|---|

| Over-the-road trucks | Monthly | 1.270-1.290 | Higher vibration demands tighter caps |

| Delivery vans | Quarterly | 1.260-1.280 | Frequent starts require cleaner acid |

| Construction equipment | Bi-weekly | 1.280-1.300 | Dust contamination prevention critical |

Fleet Maintenance Insight: Implementing centralized watering systems can reduce maintenance time by 75% while ensuring proper electrolyte levels across all vehicles.

Marine and RV Deep Cycle Optimization

Stationary storage applications need specialized approaches:

- Equalization Charging:

- 15.5V for 2-4 hours monthly prevents stratification

- Must monitor temperature – stop if exceeding 125°F (52°C)

- Winter Storage Procedures:

- Fully charge before storage (prevents freezing)

- Disconnect negative terminal

- Check SG monthly – recharge if below 1.225

Critical Warning: Marine batteries require ventilation even in storage – hydrogen gas accumulation in enclosed spaces creates explosion hazards. Always use marine-rated battery boxes.

These specialized protocols demonstrate how proper acid management must be adapted to specific use cases. The principles remain consistent, but application details make the difference between adequate and exceptional performance.

Advanced Diagnostic Techniques and Predictive Maintenance Strategies

Modern battery acid analysis goes beyond simple hydrometer readings. These professional-grade techniques enable predictive maintenance and precise performance optimization for critical applications.

Comprehensive Electrolyte Analysis Methods

Advanced diagnostic approaches provide complete acid health assessment:

| Technique | Measurement Parameters | Diagnostic Value | Equipment Cost |

|---|---|---|---|

| Atomic Absorption Spectroscopy | Lead/antimony content | Plate degradation rate | $15,000+ |

| Electrochemical Impedance Spectroscopy | Ionic resistance | Sulfation level | $3,000-$7,000 |

| Refractometry with Temperature Compensation | Precision SG measurement | State-of-charge accuracy | $200-$500 |

Practical Tip: Many battery specialty shops offer these advanced tests for $25-$75 per battery – cost-effective for critical applications when compared to premature replacement costs.

Predictive Maintenance Scheduling

Implementing data-driven maintenance prevents unexpected failures:

- Baseline Testing:

- Record initial SG, voltage, and CCA when new

- Establish normal operating parameters

- Degradation Tracking:

- Monthly SG variance analysis

- Quarterly capacity testing

- Annual deep discharge analysis

- Replacement Triggers:

- 15% SG variance from baseline

- 20% CCA reduction

- 3+ cells requiring weekly water

Case Study: Fleet operators using predictive maintenance report 37% fewer roadside failures and 28% longer average battery life compared to reactive replacement strategies.

Quality Assurance Protocols for Professional Shops

Commercial battery service requires rigorous standards:

- Acid Handling Certification: OSHA 29 CFR 1910.1200 compliance for hazardous materials

- Neutralization Station Requirements: 10:1 emergency capacity with pH monitoring

- Testing Equipment Calibration: Quarterly verification against NIST standards

- Documentation Standards: Complete service records including:

- Pre/post-service SG readings

- Water addition volumes

- Charging parameters

Industry Insight: Top-performing shops achieve 98% first-time repair success rates by combining these QA measures with trained technicians and proper equipment.

These advanced techniques represent the cutting edge of battery acid management, transforming maintenance from guesswork into a precise science with measurable outcomes and predictable performance.

Conclusion

Your car battery’s sulfuric acid is far more than just a simple liquid component – it’s the lifeblood of your vehicle’s electrical system. We’ve explored how this powerful electrolyte enables energy production through complex chemical reactions with lead plates.

From basic maintenance like checking specific gravity to advanced techniques like desulfation, proper acid management can double your battery’s lifespan. Remember that different battery types and environments require tailored approaches for optimal performance.

The financial and environmental benefits of proper acid maintenance are clear. With simple quarterly checks and using only distilled water for replenishment, you’ll save money while reducing hazardous waste.

Now that you understand what’s really inside your battery, take action. Implement these maintenance practices today to ensure reliable starts and maximum battery longevity. Your vehicle – and wallet – will thank you for years to come.

Frequently Asked Questions About Car Battery Acid

What exactly does sulfuric acid do in a car battery?

Sulfuric acid serves as the electrolyte that enables the chemical reaction between lead plates to produce electricity. When discharging, the acid reacts with lead and lead dioxide to form lead sulfate and release electrons. During charging, this process reverses, reforming the original components.

The acid’s concentration (measured as specific gravity) directly indicates battery state of charge. Properly maintained 35-40% sulfuric acid solution ensures optimal conductivity and prevents premature battery failure through sulfation or plate corrosion.

How often should I check my battery’s acid levels?

For standard flooded lead-acid batteries, check electrolyte levels every 3 months or 3,000 miles. In extreme temperatures or high-vibration vehicles, monthly checks are recommended. AGM and gel batteries are maintenance-free but still benefit from annual voltage testing.

Always check levels after long trips or deep discharges. Low electrolyte exposes plates to air, causing irreversible sulfation. Use only distilled water for replenishment – tap water contains minerals that degrade battery performance.

Why does my battery acid turn dark brown or black?

Discolored electrolyte indicates serious issues. Brown tint suggests positive plate material shedding, while black color means severe sulfation or contamination. In both cases, the battery likely needs replacement as these conditions permanently reduce capacity.

For valuable batteries, complete acid replacement might help if caught early. However, this requires professional equipment to properly flush cells and restore proper acid concentration. DIY attempts often cause more harm than good.

Can I use battery acid to recharge a dead battery?

Adding fresh acid to a discharged battery is dangerous and ineffective. Proper recharging requires converting lead sulfate back to its original components through controlled electrical current. Simply adding acid creates excessive heat and pressure that can crack the case.

The only exception is when a battery has been completely drained and refilled with water. Even then, use only diluted acid (28-32%) and charge slowly at 2 amps to prevent thermal runaway. Professional servicing is strongly recommended.

How do I safely clean battery acid spills?

Immediately neutralize spills with baking soda solution (1 cup per gallon of water). Wear gloves and eye protection. The neutralization reaction will bubble – continue applying until bubbling stops. Wipe with paper towels and dispose as hazardous waste.

For clothing or skin contact, flush immediately with copious water for 15 minutes. Seek medical attention for eye exposure or large skin contact. Never mix acid with other cleaners – especially bleach which creates toxic chlorine gas.

What’s the difference between battery acid and distilled water additions?

During normal operation, only water evaporates from the electrolyte solution. Adding acid increases concentration, accelerating plate corrosion. Distilled water maintains the proper 35% acid/65% water balance needed for optimal performance.

The exception is after complete electrolyte replacement or when specific gravity remains below 1.225 after full charging. Use a refractometer to test – if low, a professional may add diluted acid to restore proper concentration.

Why does my battery lose water so quickly?

Rapid water loss typically indicates overcharging from a faulty voltage regulator. Test charging system voltage – it should be 13.8-14.4V at 2000 RPM. Higher voltages boil off electrolyte excessively.

Other causes include high underhood temperatures, frequent deep cycling, or using the wrong charger setting. AGM batteries shouldn’t lose water – if they do, replace immediately as the sealed design has failed.

Can I extend my battery’s life with additives?

Some sulfate-reducing additives can help mildly sulfated batteries, but results vary. EDTA-based solutions work best for dissolving sulfate crystals. Avoid “miracle” products claiming to restore dead batteries – they often contain harmful abrasives.

Proper maintenance provides better results than additives. Regular charging, clean terminals, and correct water levels do more to extend life. For valuable batteries, professional reconditioning services offer more reliable restoration than consumer additives.