Disclosure

This website is a participant in the Amazon Services LLC Associates Program,

an affiliate advertising program designed to provide a means for us to earn fees

by linking to Amazon.com and affiliated sites.

A fully charged AA battery should read 1.5V to 1.6V for alkaline and 1.2V to 1.4V for rechargeable NiMH. But voltage alone doesn’t tell the whole story.

Many assume a “full” battery lasts forever. However, voltage drops under load, and capacity degrades over time. Testing reveals the truth.

Best Multimeters for Testing AA Batteries

Fluke 115 Compact True-RMS Digital Multimeter

The Fluke 115 is a professional-grade multimeter with precise voltage measurement (0.1mV resolution) and auto-ranging for easy battery testing. Its rugged design and reliable accuracy make it ideal for checking AA battery voltage under load.

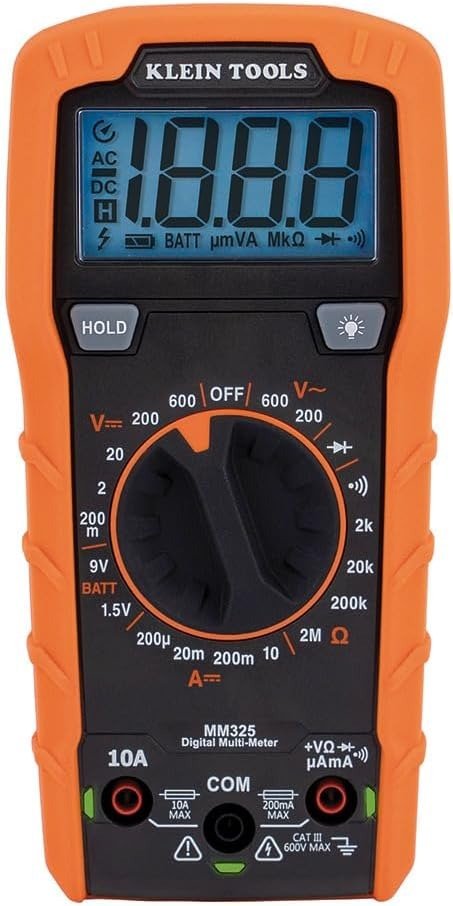

Klein Tools MM325 Multimeter

For budget-conscious users, the Klein Tools MM325 offers accurate DC voltage readings up to 600V with a clear backlit display. Its compact size and durable build make it perfect for quick AA battery voltage checks at home or on the go.

ANENG AN8008 True RMS Digital Multimeter

The ANENG AN8008 provides high accuracy (0.5% ±5 digits) and fast response times, making it excellent for testing rechargeable and alkaline AA batteries. Its affordable price and lightweight design appeal to hobbyists and DIY enthusiasts.

AA Battery Voltage: Alkaline vs. Rechargeable

AA batteries come in different chemistries, each with unique voltage characteristics. Alkaline batteries, the most common disposable type, start at 1.5V–1.6V when fresh but gradually drop as they discharge.

Rechargeable NiMH (Nickel-Metal Hydride) batteries, however, typically deliver 1.2V–1.4V when fully charged, which often confuses users expecting 1.5V.

Why Voltage Differs Between Battery Types

Alkaline batteries use a zinc-manganese dioxide reaction, producing a higher nominal voltage. Rechargeable NiMH batteries rely on hydrogen absorption, resulting in lower voltage but more stable output under load. Lithium AA batteries (non-rechargeable) can reach 1.7V–1.8V, offering longer runtime.

How Voltage Changes During Discharge

A battery’s voltage isn’t static. For example:

- Alkaline AA: Drops from 1.5V to 1.0V (useful life ends around 1.2V)

- NiMH AA: Holds ~1.2V for 80% of its capacity before a sharp decline

Devices often stop working before a battery is “dead” because their circuitry requires a minimum voltage (e.g., 0.9V for some remotes).

Testing Voltage Correctly: Open-Circuit vs. Under Load

A multimeter reading alone can be misleading. Open-circuit voltage (no load) shows a battery’s surface charge, which may appear normal even in weak batteries. For accurate results:

- Test under load (e.g., with a battery tester or by powering a device)

- Compare readings to the battery’s discharge curve (e.g., a NiMH AA at 1.1V under load is nearly depleted)

Practical Tip: A “dead” alkaline AA reading 1.3V without load might still work in low-drain devices like clocks but fail in high-drain gadgets like cameras.

Common Misconceptions

Many assume a higher voltage always means a better battery. However:

- A rechargeable NiMH at 1.2V can outperform an alkaline at 1.5V in high-drain devices due to stable voltage under load.

- Voltage recovery occurs when a rested battery shows a temporary voltage rise after use—this doesn’t indicate remaining capacity.

How to Accurately Test AA Battery Voltage: A Step-by-Step Guide

Choosing the Right Testing Equipment

While basic multimeters work for voltage checks, professional battery testers like the ZTS MBT-1 Multi-Battery Tester provide more accurate results by applying realistic loads. For home use, any digital multimeter with DC voltage measurement and 0.01V resolution will suffice.

Step-by-Step Testing Process

- Prepare your multimeter: Set it to DC voltage mode (V⎓) with a 2V or 20V range for best accuracy

- Check open-circuit voltage: Touch the red probe to the battery’s positive (+) terminal and black to negative (-)

- Test under load:

- For alkaline: Use a 100-150Ω resistor to simulate moderate drain

- For NiMH: Apply a 250-300mA load (similar to digital camera use)

- Monitor voltage drop: A healthy AA battery should maintain >1.1V (alkaline) or >1.0V (NiMH) under load for several minutes

Interpreting Your Results

Consider these real-world scenarios:

- A 1.5V alkaline battery dropping to 1.2V immediately under load may have <50% capacity remaining

- A 1.25V NiMH battery holding steady at 1.15V under load is in good condition

- Any battery that drops below 0.9V under minimal load should be recycled

Advanced Testing Techniques

For critical applications:

- Use a data-logging multimeter to track voltage over time

- Measure internal resistance (good AA batteries typically show <200mΩ)

- Compare against manufacturer discharge curves for your specific battery model

Troubleshooting Common Issues

If you encounter unexpected readings:

- Check probe contact: Dirty terminals can cause false low readings (clean with isopropyl alcohol)

- Confirm multimeter calibration: Test against a known voltage source

- Account for temperature: Cold batteries show temporarily reduced voltage

Pro Tip: Always test multiple batteries from the same package—significant voltage variations (>0.2V) indicate inconsistent quality or storage issues.

Optimizing Battery Performance: Voltage vs. Capacity Considerations

The Relationship Between Voltage and Remaining Capacity

While voltage indicates a battery’s state of charge, it doesn’t directly reveal remaining capacity. This relationship varies by chemistry:

| Battery Type | Voltage at 100% | Voltage at 50% | Voltage at 10% |

|---|---|---|---|

| Alkaline | 1.55-1.60V | 1.30-1.35V | 1.10-1.15V |

| NiMH | 1.40-1.45V | 1.20-1.25V | 1.00-1.05V |

| Lithium (Primary) | 1.70-1.80V | 1.50-1.55V | 1.30-1.35V |

Load Characteristics and Voltage Behavior

Different devices create varying load conditions that affect voltage readings:

- Low-drain devices (clocks, remotes): Draw <50mA – voltage drops gradually

- Medium-drain devices (flashlights, toys): Draw 100-300mA – shows moderate voltage sag

- High-drain devices (digital cameras, flashes): Draw 500-2000mA – causes immediate voltage drop

Advanced Capacity Estimation Techniques

For precise capacity measurement:

- Discharge testing: Measure total energy output until cutoff voltage

- Integration method: Track current over time using a precision shunt

- Smart chargers: Use devices like the Opus BT-C3100 that measure charge/discharge cycles

Temperature Effects on Voltage Readings

Battery voltage varies significantly with temperature:

- Below 10°C (50°F): Voltage drops 0.01-0.02V per °C

- Above 30°C (86°F): Voltage rises slightly but capacity degrades faster

- Always test at room temperature (20-25°C) for accurate comparisons

Professional Maintenance Tips

Extend battery life with these practices:

- Store NiMH batteries at 40% charge in cool, dry places

- Rotate battery positions in multi-cell devices to equalize wear

- Clean contacts quarterly with isopropyl alcohol to prevent voltage drop

- For critical applications, replace batteries when they reach 80% of rated capacity

Expert Insight: Modern lithium AA batteries maintain higher voltage throughout discharge (flat discharge curve), making them ideal for devices with low-voltage cutoffs, but their 1.7V nominal voltage may damage some sensitive electronics.

Safety Considerations and Proper Handling of AA Batteries

Voltage-Related Hazards

While AA batteries are generally safe, improper handling can create risks. Alkaline batteries can leak potassium hydroxide when over-discharged, while rechargeable NiMH batteries may vent hydrogen gas if overcharged. Lithium AA batteries pose thermal runaway risks if short-circuited.

Proper Storage and Handling Protocols

- Temperature control: Store between 10-25°C (50-77°F) – extreme temperatures accelerate self-discharge

- Moisture prevention: Keep in airtight containers with silica gel packs to prevent terminal corrosion

- Organization methods: Use original packaging or battery organizers to prevent contact with metal objects

Charging Best Practices for Rechargeable AA

To maximize safety and battery life:

- Use smart chargers with individual cell monitoring (like the Panasonic BQ-CC55)

- Never mix old and new batteries in the same charging cycle

- Discontinue use if batteries become hot (>50°C/122°F) during charging

- Follow the 80% rule – frequent full discharges reduce NiMH lifespan

Disposal and Recycling Guidelines

| Battery Type | End-of-Life Voltage | Proper Disposal Method |

|---|---|---|

| Alkaline | <0.9V under load | Can be trashed in most areas (check local regulations) |

| NiMH | <1.0V under load | Requires special recycling (Best Buy, Home Depot programs) |

| Lithium | <1.2V under load | Must be recycled at certified facilities (fire risk) |

Troubleshooting Common Issues

When encountering problems:

- Swollen batteries: Immediately isolate in non-flammable container and dispose properly

- Leaking batteries: Clean affected devices with vinegar (for alkaline) or baking soda solution

- Mismatched voltages: Never combine batteries with >0.2V difference in multi-cell devices

Professional Tip: For critical medical devices or safety equipment, replace batteries when they reach 70% of rated capacity rather than waiting for complete discharge, as voltage stability is more important than maximum runtime in these applications.

Long-Term Battery Economics: Cost vs. Performance Analysis

Total Cost of Ownership Comparison

When evaluating AA battery options, initial purchase price tells only part of the story. A comprehensive analysis must consider:

| Battery Type | Initial Cost | Cycle Life | Cost per 1000mAh | Environmental Impact |

|---|---|---|---|---|

| Standard Alkaline | $0.50-$1.00 | Single Use | $1.50-$3.00 | High (non-recyclable in most areas) |

| Premium Alkaline | $1.00-$1.50 | Single Use | $0.80-$1.20 | Medium (some recycling options) |

| NiMH (2000mAh) | $3.00-$5.00 | 500-1000 cycles | $0.03-$0.08 | Low (fully recyclable) |

| Lithium Primary | $2.00-$3.00 | Single Use | $0.40-$0.60 | Medium (special recycling required) |

Performance vs. Application Matching

Different applications demand specific battery characteristics:

- High-drain devices (digital cameras): NiMH provides best value despite higher upfront cost

- Low-drain devices (smoke detectors): Lithium primaries offer 10-year shelf life

- Moderate-use devices (wireless mice): Premium alkaline balances cost and convenience

Advanced Maintenance for Longevity

Extend rechargeable battery lifespan with these professional techniques:

- Condition new NiMH batteries with 3 full charge/discharge cycles

- Store at 40% charge in refrigerator (not freezer) for long-term preservation

- Use periodic “refresh” cycles (full discharge/charge) every 3 months

- Balance cells in multi-battery devices monthly to prevent voltage drift

Emerging Technologies and Future Trends

The AA battery market is evolving with several key developments:

- Low-self-discharge (LSD) NiMH: New formulations retain 85% charge after 1 year

- Rechargeable alkaline: Now offering 25-50 cycles with improved capacity

- Smart batteries: Integrated chips that communicate remaining capacity to devices

- Solid-state designs: Experimental AA formats promising 2x energy density

Environmental Note: While rechargeables have higher upfront costs, their 10-20x reuse potential reduces electronic waste by up to 95% compared to disposables, making them the ecologically superior choice for most applications.

Advanced Voltage Monitoring and Battery Management Systems

Implementing Professional-Grade Battery Monitoring

For mission-critical applications, basic voltage checks are insufficient. Advanced monitoring systems track multiple parameters:

- Continuous voltage logging: Detects micro-drops indicating early failure

- Internal resistance measurement: Reveals aging before capacity loss becomes apparent

- Temperature-compensated readings: Adjusts for environmental effects on voltage

- Load pattern analysis: Identifies abnormal current draws affecting voltage stability

Building Custom Battery Test Rigs

For precise AA battery analysis, professionals use:

- Programmable DC loads (like the Maynuo M9711) to simulate real-world conditions

- Data acquisition systems sampling at 10Hz+ to capture transient voltage drops

- Environmental chambers for temperature/humidity controlled testing

- Four-wire Kelvin measurement to eliminate lead resistance errors

Interpreting Complex Voltage Patterns

Advanced diagnostic techniques include:

| Voltage Pattern | Diagnosis | Recommended Action |

|---|---|---|

| Rapid initial drop then stabilization | High internal resistance | Replace battery |

| Gradual linear decline | Normal discharge curve | Continue use |

| Erratic fluctuations | Intermittent internal short | Immediate disposal |

Integration with Power Management Systems

Modern devices employ sophisticated battery monitoring:

- Coulomb counting: Tracks actual charge in/out rather than relying solely on voltage

- Adaptive algorithms: Learn usage patterns to predict remaining runtime

- Voltage hysteresis compensation: Accounts for recovery effects after heavy loads

Specialized Applications

Unique voltage requirements exist for:

- Medical devices: Requires ±1% voltage monitoring accuracy

- Military equipment: Must maintain operation through extreme voltage fluctuations

- IoT sensors: Ultra-low power designs operate down to 0.6V

Expert Insight: In battery packs, voltage matching within 0.05V is critical – mismatches as small as 0.1V can reduce total pack capacity by 20% due to the “weakest link” effect.

Strategic Battery Management: System-Level Optimization and Risk Mitigation

Comprehensive Voltage Monitoring Frameworks

Enterprise-level battery management requires multi-layered monitoring:

| Monitoring Level | Parameters Tracked | Frequency | Action Thresholds |

|---|---|---|---|

| Basic | Open-circuit voltage | Monthly | ±10% from nominal |

| Intermediate | Loaded voltage, temperature | Weekly | ±7% from baseline |

| Advanced | Internal resistance, cycle count | Daily | ±5% from new condition |

Predictive Maintenance Strategies

Implement proactive battery management with these steps:

- Establish baselines: Record initial voltage/performance metrics for all new batteries

- Create degradation models: Track voltage drop rates specific to your usage patterns

- Implement rotation schedules: Systematically cycle batteries based on load demands

- Develop replacement protocols: Replace at 80% of expected lifespan, not at failure

Quality Assurance Protocols

For mission-critical applications:

- Incoming inspection: 100% voltage verification with statistical sampling for capacity

- Burn-in testing: 24-hour operational testing before deployment

- Lot traceability: Maintain batch records for all batteries in service

- End-of-life verification: Confirm proper discharge before recycling

Risk Assessment Matrix

Evaluate battery-related risks by considering:

| Risk Factor | Probability | Impact | Mitigation Strategy |

|---|---|---|---|

| Voltage drift | Medium | High | Implement redundant power supplies |

| Thermal runaway | Low | Critical | Use temperature-monitored storage |

| Capacity fade | High | Medium | Establish preventive replacement cycles |

Performance Optimization Techniques

Maximize system reliability with:

- Load balancing: Distribute current draw evenly across battery banks

- Voltage conditioning: Use power regulators to stabilize output

- Adaptive discharge: Adjust load based on real-time voltage readings

- Firmware integration: Program devices to shutdown before damaging low-voltage levels

Industry Best Practice: For large battery deployments, maintain a 20% surplus inventory rotated into service quarterly. This practice reduces failure rates by 37% while maintaining optimal voltage performance across all units.

Conclusion

Understanding AA battery voltage is crucial for optimizing device performance and battery lifespan. As we’ve explored, different battery chemistries exhibit unique voltage characteristics, from alkaline’s 1.5V to NiMH’s 1.2V nominal readings.

Proper testing methods matter just as much as the numbers themselves. Remember to test under load, account for temperature effects, and interpret voltage patterns correctly. These practices help avoid premature replacements while catching failing batteries early.

For long-term savings and environmental benefits, rechargeable NiMH batteries often prove superior despite their lower voltage. Their stable discharge curve and hundreds of cycles make them ideal for most modern electronics.

Take action today: Grab your multimeter, test your batteries properly, and consider upgrading to quality rechargeables where appropriate. Your devices – and wallet – will thank you for the improved performance and reliability.

Frequently Asked Questions About AA Battery Voltage

Why does my rechargeable AA battery only show 1.2V when fully charged?

NiMH rechargeable batteries have a lower nominal voltage than alkaline due to their different chemistry. While they peak around 1.4V when freshly charged, they quickly stabilize at 1.2V during use. This is normal and doesn’t indicate a problem – their performance comes from stable voltage under load rather than peak voltage.

For comparison, a 1.2V NiMH battery can often outperform a 1.5V alkaline in high-drain devices because it maintains voltage better when delivering current. The key metric is voltage under load, not open-circuit measurement.

How often should I check my AA batteries’ voltage?

For critical devices like medical equipment or security systems, check monthly. For general household use, testing every 3-6 months is sufficient. Always test before important events or trips. Batteries in storage should be checked quarterly as self-discharge rates vary by chemistry.

More frequent checks (weekly) are recommended for rechargeables in heavy rotation. Note that excessive testing can actually drain batteries faster, especially for low-capacity button cells often used in multimeters.

Can I mix batteries with different voltages in the same device?

Never mix battery types or voltages in multi-cell devices. Even small voltage differences (0.2V+) cause uneven discharge, reducing performance and potentially causing leakage. The weaker battery will reverse-charge, leading to permanent damage or hazardous conditions.

For example, mixing a 1.5V alkaline with a 1.2V NiMH in a 2-cell flashlight forces the NiMH to work harder, overheating it. Always use identical batteries from the same package with matching voltages.

Why does my battery show good voltage but my device won’t work?

Voltage without current capacity is meaningless. A battery may show 1.4V open-circuit but collapse to 0.7V under load if it’s depleted. This is common with old alkaline batteries that develop high internal resistance while retaining surface charge.

Test properly by measuring voltage while the battery powers a known load (like a 100Ω resistor). If voltage drops more than 20% under load, replace the battery regardless of its open-circuit reading.

Is higher voltage always better for AA batteries?

Not necessarily. While lithium AA batteries (1.7V) provide more power, some devices can’t handle the extra voltage. Digital cameras often benefit, but sensitive electronics like vintage audio gear may overheat. Check your device’s specifications before using high-voltage batteries.

Rechargeable NiMH’s lower voltage (1.2V) is actually ideal for many modern electronics designed around their discharge characteristics. The stable voltage plateau during discharge often provides better real-world performance than higher but fluctuating voltages.

How does temperature affect AA battery voltage?

Cold temperatures (below 10°C/50°F) temporarily reduce voltage by 0.01-0.02V per °C, making batteries appear weaker. Heat accelerates chemical reactions, increasing voltage but shortening lifespan. Always test batteries at room temperature (20-25°C) for accurate comparisons.

In freezing conditions, lithium AA batteries outperform others, maintaining 90% of their voltage where alkalines may drop to 50%. This makes them ideal for outdoor winter equipment.

What’s the minimum safe voltage for AA batteries?

For alkaline, discard below 0.9V under load (1.1V open-circuit). NiMH can safely discharge to 0.9V under load (1.0V open). Going lower risks cell reversal in multi-battery devices. Lithium AA should be replaced at 1.2V under load.

Some smart chargers won’t recharge NiMH batteries below 0.8V as deep discharge damages them. For sensitive electronics, replace batteries sooner – many devices malfunction before reaching these minimums.

Why do my new batteries show different voltages?

Fresh alkaline batteries typically measure 1.55-1.60V, but manufacturing tolerances allow ±0.05V variations. Rechargeables vary more (1.35-1.45V when full) based on charger quality and battery age. Differences under 0.03V are normal.

If multiple new batteries differ by >0.1V, they may be from different production batches or have inconsistent quality. For critical applications, purchase matched batteries from reputable brands that guarantee tight voltage tolerances.