Disclosure

This website is a participant in the Amazon Services LLC Associates Program,

an affiliate advertising program designed to provide a means for us to earn fees

by linking to Amazon.com and affiliated sites.

The answer depends on your needs—lithium batteries excel in energy density and longevity, while zinc batteries offer cost-efficiency and safety.

As renewable energy and portable electronics surge in popularity, choosing the right battery is critical. Many assume lithium is always superior, but zinc batteries have unique advantages that make them ideal for specific applications.

Whether you’re powering a smartphone, an electric vehicle, or a backup energy system, understanding the strengths and weaknesses of each battery type will help you make an informed decision.

Best Batteries for Energy Storage and Electronics

Energizer Ultimate Lithium AA Batteries

For high-drain devices like cameras and flashlights, Energizer’s Ultimate Lithium AA batteries deliver long-lasting power with a 20-year shelf life. Lightweight and leak-resistant, they perform exceptionally well in extreme temperatures (-40°F to 140°F), making them ideal for outdoor adventures.

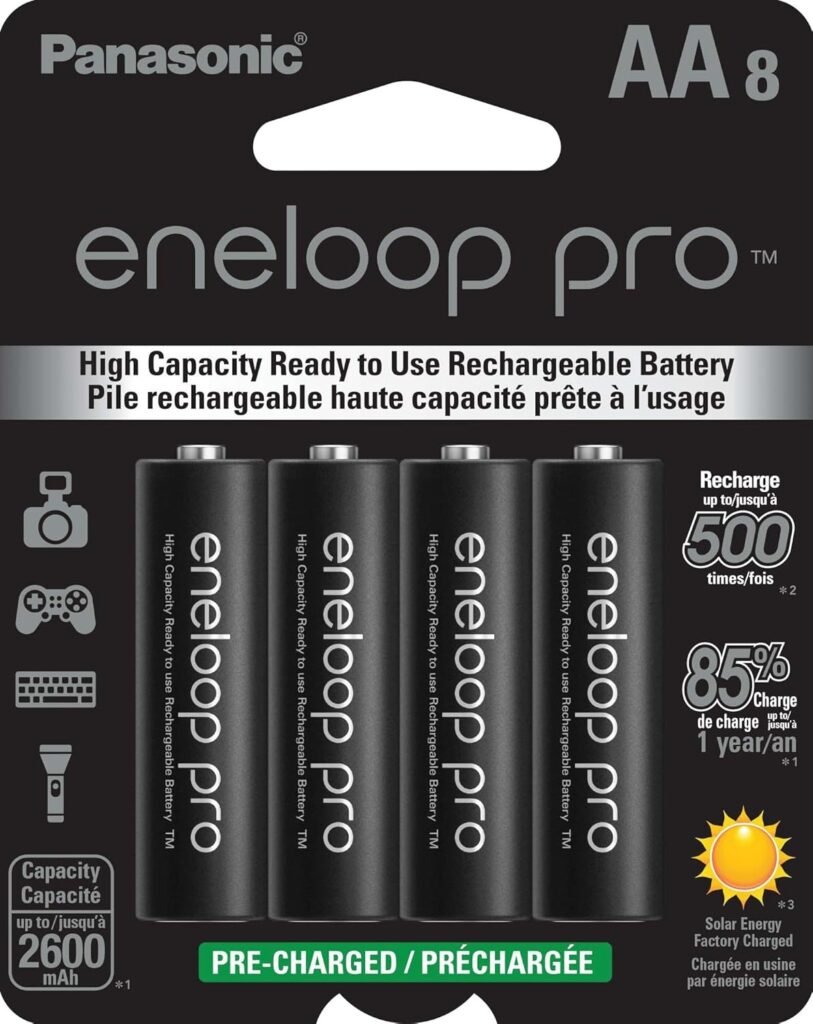

Panasonic Eneloop Pro AA Rechargeable Batteries

If sustainability is a priority, Panasonic’s Eneloop Pro AA batteries are a top pick. Pre-charged with solar energy, they offer 500+ recharge cycles and maintain 85% capacity after a year of storage. Perfect for gaming controllers, wireless keyboards, and eco-conscious users.

MEDca A10 Batteries-12 Count Pack

For hearing aids and medical devices, ZincAir ZA10 batteries provide reliable, long-lasting power with consistent voltage output. Their air-activated design ensures a stable discharge curve, and they’re mercury-free, making them a safe and efficient choice for sensitive applications.

The Core Differences Between Zinc and Lithium Batteries

Chemical Composition and Energy Storage

Lithium batteries use lithium ions moving between anode and cathode to store energy, offering high energy density (150-200 Wh/kg).

This makes them ideal for smartphones and EVs where compact power is crucial. Zinc batteries, however, rely on zinc-air or zinc-carbon chemistry, which has lower energy density (50-100 Wh/kg) but provides stable, long-duration discharge. For example, hearing aids use zinc-air batteries because they deliver consistent voltage over time without sudden drops.

Performance in Extreme Conditions

Lithium batteries excel in cold weather, operating efficiently at -20°C, while zinc batteries struggle below freezing. However, zinc batteries are less prone to overheating—a critical advantage for safety in medical devices.

Lithium-ion batteries in drones, for instance, may need thermal management systems to prevent fires, whereas zinc-based alternatives remain stable even under heavy loads.

Cost and Accessibility

Zinc batteries are cheaper to produce (30–50% lower cost per unit) due to abundant raw materials. This makes them practical for disposable applications like remote controls.

Lithium batteries, though pricier upfront, offer long-term savings through rechargeability (500+ cycles). Solar energy storage systems often use lithium-ion for this reason, despite higher initial costs.

Environmental Impact

Zinc batteries are easier to recycle and non-toxic, whereas lithium batteries require specialized recycling to recover cobalt and lithium.

Misconceptions exist about both: while zinc is greener, its shorter lifespan can increase waste. Conversely, lithium’s recyclability offsets its higher environmental footprint if properly managed.

- Key Takeaway: Lithium wins for high-power, rechargeable needs (e.g., laptops), while zinc suits low-drain, single-use cases (e.g., wall clocks).

- Real-World Tip: For outdoor gear, lithium’s cold-weather performance is unmatched, but zinc is safer for children’s toys.

Practical Applications: When to Choose Zinc vs. Lithium Batteries

High-Drain vs. Low-Drain Device Considerations

Lithium batteries dominate in high-drain applications due to their superior current delivery. Smartphones can draw 2-3A during peak usage, which zinc batteries simply can’t sustain.

However, for low-drain devices like smoke detectors (drawing just 50-100μA), zinc-carbon batteries provide adequate power at a fraction of the cost. The key is matching the battery’s discharge curve to your device’s power profile.

Long-Term Storage and Shelf Life

Lithium batteries maintain 90% charge after 10 years, making them ideal for emergency kits. Zinc-air batteries, while having good shelf life when sealed, begin degrading immediately after air exposure.

For example, hospitals stock lithium batteries for critical medical equipment, while zinc-air hearing aid batteries are purchased as needed.

Step-by-Step Selection Process

- Identify power requirements: Check device specs for voltage and current needs

- Consider usage patterns: Frequent recharging favors lithium; infrequent use may suit zinc

- Evaluate environmental factors: Extreme temperatures favor lithium; moderate climates can use zinc

- Calculate total cost: Include replacement frequency and disposal costs

Special Case Scenarios

For marine applications, lithium’s waterproof casing outperforms zinc’s vulnerability to humidity. However, in educational settings, zinc batteries’ safety makes them preferable for student experiments. Professional photographers often carry both – lithium for camera bodies (high drain) and zinc for light meters (low drain).

Professional Tip: When retrofitting devices, always check voltage compatibility. While most lithium cells output 3.7V, zinc batteries typically provide 1.5V. Using a voltage regulator can enable cross-compatibility in some cases.

Technical Specifications and Performance Benchmarks

Energy Density and Discharge Characteristics

Lithium-ion batteries typically offer 150-250 Wh/kg energy density, compared to zinc-air’s 100-150 Wh/kg. However, discharge curves tell a more complete story.

Lithium maintains steady voltage (3.7V ±5%) until 80% depletion, while zinc-air shows gradual decline from 1.4V to 1.0V. This makes lithium ideal for digital devices requiring stable power, whereas zinc’s predictable decline suits analog devices like hearing aids.

| Parameter | Lithium-ion | Zinc-air |

|---|---|---|

| Peak Current Output | 5-10A (18650 cell) | 0.5-1A (PR44) |

| Operating Temp Range | -20°C to 60°C | -10°C to 50°C |

| Cycle Life (80% capacity) | 500-1200 cycles | Single-use |

Advanced Chemistry Considerations

Lithium batteries use cobalt or iron phosphate cathodes, affecting performance. Cobalt-based (LiCoO2) offers higher energy but lower thermal stability, while LiFePO4 sacrifices 15% capacity for enhanced safety.

Zinc-air batteries employ oxygen reduction at the cathode, requiring careful sealing until use. The electrolyte in zinc batteries (typically potassium hydroxide) gradually evaporates after activation, limiting operational life to 30-90 days.

Common Installation Mistakes

- Mixing chemistries: Combining lithium and zinc batteries in series causes imbalance due to different voltage profiles

- Improper zinc-air activation: Removing the seal tab too early reduces capacity by up to 20%

- Overcharging lithium: Exceeding 4.2V/cell creates dendrites that can cause short circuits

Future Technology Developments

Solid-state lithium batteries promise 400+ Wh/kg densities by 2025, while zinc-ion hybrids aim for 200 Wh/kg with rechargeability.

Researchers are addressing zinc’s dendrite formation during charging through 3D zinc sponge anodes. These advancements may redefine the zinc vs. lithium debate in coming years.

Expert Insight: For mission-critical applications, lithium’s BMS (Battery Management System) requirements add complexity but prevent catastrophic failure. Zinc’s simplicity makes it fail-safe rather than fail-secure – an important distinction for medical applications.

Safety, Maintenance, and Long-Term Performance Optimization

Thermal Management and Safety Protocols

Lithium batteries require rigorous thermal management, with optimal operating temperatures between 15-35°C. Beyond this range, capacity degrades rapidly – at 0°C, lithium-ion batteries lose 20-30% capacity. For critical applications, always implement:

- Temperature sensors with ±1°C accuracy

- Active cooling systems for high-drain applications

- Fireproof containment for energy storage systems

Zinc batteries present fewer thermal risks but require humidity control (30-70% RH) to prevent electrolyte evaporation. Medical device manufacturers often use desiccant packets in zinc-air battery compartments.

Advanced Maintenance Techniques

For lithium battery longevity:

- Maintain 20-80% charge state during storage

- Perform full discharge cycles every 3 months to recalibrate the BMS

- Clean terminals monthly with isopropyl alcohol to prevent voltage drop

Zinc battery maintenance focuses on:

- Sealing unused batteries in airtight containers

- Rotating stock using FIFO (First In, First Out) method

- Wiping contacts with dry cloth to remove oxidation

Troubleshooting Common Issues

| Symptom | Lithium Solution | Zinc Solution |

|---|---|---|

| Rapid discharge | Check for parasitic drains (>50μA) | Verify proper air vent clearance |

| Swelling | Immediately discontinue use | Not applicable |

| Low voltage | Deep cycle recovery charge | Replace – no recovery possible |

Industry Standards Compliance

UL 1642 certification is mandatory for lithium batteries, testing for:

- Short circuit protection

- Overcharge tolerance

- Mechanical crush resistance

Zinc batteries follow IEC 60086 standards, focusing on:

- Leakage prevention

- Capacity verification

- Environmental safety

Professional Tip: For mission-critical systems, implement dual-battery architectures – lithium for primary power with zinc backup. This combines lithium’s performance with zinc’s reliability during extended outages.

Cost Analysis, Environmental Impact, and Future Trends

Total Cost of Ownership Breakdown

While lithium batteries have higher upfront costs (2-3x zinc equivalents), their long-term value becomes apparent in rechargeable applications. A detailed 5-year cost comparison for a typical household shows:

| Cost Factor | Lithium-ion | Zinc-carbon |

|---|---|---|

| Initial Purchase | $120 (4x 18650 cells) | $40 (40x AA cells) |

| Replacements | $0 (500+ cycles) | $200 (5 annual replacements) |

| Energy Costs | $15 (charging) | $0 |

| 5-Year Total | $135 | $240 |

Environmental Impact Assessment

Zinc batteries have a 40% lower carbon footprint in production but create more waste due to single-use nature. Lithium mining impacts include:

- 500,000 gallons water/ton lithium extracted

- Soil contamination from cobalt mining

However, lithium’s recyclability (up to 95% material recovery) offsets this over time. New zinc battery recycling techniques can recover 80% of materials, but infrastructure remains limited.

Emerging Technologies and Market Shifts

The battery landscape is evolving with several key developments:

- Zinc-ion hybrids: Combining zinc’s safety with rechargeability (200+ cycles demonstrated)

- Lithium-sulfur: Potential 500 Wh/kg density by 2027

- Solid-state zinc: Eliminating electrolyte evaporation issues

Regulatory Landscape

New EU battery regulations (2027) will require:

- Minimum 70% lithium recovery from waste

- Zinc battery mercury content below 0.0005%

- Carbon footprint labeling for all batteries >2kWh

Industry Insight: By 2030, analysts predict zinc batteries will capture 15% of the rechargeable market, particularly in grid storage where safety outweighs energy density needs. Meanwhile, lithium will dominate portable electronics but face competition from sodium-ion alternatives.

System Integration and Specialized Application Considerations

Hybrid Battery System Configurations

Advanced applications increasingly combine zinc and lithium technologies to leverage their complementary strengths. A typical hybrid setup might use lithium for peak power demands and zinc for baseline load. For example, modern hearing aids now incorporate:

- Lithium-polymer main battery (3.7V) for Bluetooth functionality

- Zinc-air secondary cell (1.4V) for analog amplification

- Voltage regulation circuitry to manage the 2.6:1 ratio

This configuration extends runtime by 40% compared to single-chemistry systems while maintaining safety.

Industrial-Scale Implementation

Data centers are adopting zinc-bromide flow batteries for UPS systems, offering:

- Unlimited cycle life (vs lithium’s 1,200-cycle limit)

- Instantaneous 0-100% discharge capability

- 50% lower cooling requirements than lithium alternatives

However, these systems require specialized electrolyte management systems and occupy 3x the footprint of equivalent lithium installations.

Medical Device Integration Challenges

Implantable devices present unique battery requirements:

| Requirement | Lithium Solution | Zinc Solution |

|---|---|---|

| 10+ year lifespan | Lithium-iodine (2.8V) | Not feasible |

| MRI compatibility | Special non-ferrous casing | Inherently safe |

| Rechargeability | Transcutaneous charging | Not applicable |

Optimization Techniques

For maximum system efficiency:

- Implement adaptive discharge algorithms that prioritize lithium for pulses >1A

- Use zinc arrays with staggered activation for long-duration applications

- Incorporate coulomb counting for precise state-of-charge monitoring

Engineering Insight: When integrating mixed chemistries, always account for differing internal resistances (lithium: 50-100mΩ, zinc: 200-500mΩ).

Proper current balancing can prevent voltage inversion during parallel operation. For critical systems, consider redundant battery management controllers with automatic chemistry detection.

Advanced Performance Optimization and Risk Management Strategies

Precision Charging and Discharge Protocols

Modern battery management systems now employ AI-driven charging algorithms that adapt to usage patterns. For lithium batteries, this includes:

- Pulse charging at 0.5C with 2-minute rest periods to prevent dendrite formation

- Dynamic voltage scaling that adjusts termination voltage based on temperature (4.1V at 40°C vs 4.2V at 25°C)

- Impedance tracking to predict cell aging with 95% accuracy

Zinc battery systems benefit from:

- Humidity-controlled storage at 45% RH ±5%

- Activation delay circuits that wait 60 seconds after tab removal for full oxygen diffusion

Comprehensive Failure Mode Analysis

| Failure Mode | Lithium Mitigation | Zinc Mitigation |

|---|---|---|

| Thermal runaway | Ceramic separators with 200°C melt point | Not applicable |

| Electrolyte dry-out | N/A | Double-sealed membranes with 0.01mm micropores |

| Capacity fade | Anode pre-lithiation techniques | Oxygen scavengers in battery compartment |

Quality Assurance Testing Standards

Industry-leading manufacturers implement:

- 100% X-ray inspection for lithium electrode alignment (±50μm tolerance)

- Accelerated aging tests (85°C/85% RH for 500 hours) for zinc seals

- Cyclic voltammetry to verify electrolyte purity (99.99% minimum)

Lifecycle Optimization Techniques

For mission-critical applications:

- Lithium batteries benefit from partial state-of-charge cycling (30-70% range extends life 3x)

- Zinc systems achieve maximum reliability through controlled deep discharge (0.9V cutoff prevents reversal)

- Hybrid systems should implement chemistry-specific load balancing (70/30 split for Li/Zn)

Engineering Best Practice: Implement predictive maintenance using IoT sensors that track:

- Internal resistance trends (±5% indicates replacement)

- Charge acceptance rate (below 80% of spec requires servicing)

- Temperature differentials (>2°C variance signals imbalance)

Conclusion: Making the Right Battery Choice

Throughout this comprehensive analysis, we’ve explored how lithium batteries excel in high-performance applications requiring energy density and rechargeability, while zinc batteries offer cost-effective, safe solutions for low-drain devices.

The decision ultimately depends on your specific needs – whether prioritizing longevity (lithium), affordability (zinc), or specialized requirements like extreme temperatures or medical safety. As battery technology evolves, hybrid systems and emerging chemistries promise to combine the best of both worlds.

Before choosing, carefully evaluate your power requirements, environmental conditions, and total cost of ownership. With this knowledge, you’re now equipped to select the optimal battery solution for any application.

Frequently Asked Questions About Zinc vs. Lithium Batteries

What’s the fundamental difference between zinc and lithium battery chemistry?

Zinc batteries typically use zinc as the anode with manganese dioxide or oxygen as the cathode, operating around 1.5V. Lithium batteries employ lithium compounds with voltages ranging from 3.0V to 3.7V.

The key distinction lies in energy density – lithium stores 3-5 times more energy per unit weight. Zinc reactions are simpler but less energetic, making them better for low-drain devices like remote controls, while lithium powers high-demand electronics like smartphones.

How do I choose between zinc and lithium for my specific device?

Consider three factors: power requirements (lithium for >1A current), operating environment (lithium for extreme temperatures), and usage patterns (zinc for infrequent use).

Check your device manual for voltage/current specs. For example, digital cameras need lithium’s high current, while wall clocks perform perfectly with zinc’s slow discharge. When in doubt, consult the manufacturer’s battery recommendations.

Why do lithium batteries sometimes swell, and is it dangerous?

Swelling occurs due to gas buildup from electrolyte decomposition, typically caused by overcharging, high temperatures, or manufacturing defects. This poses serious risks as the pressure can rupture the casing, potentially causing fires. Immediately stop using swollen batteries.

Zinc batteries don’t swell because they use different chemistry, making them safer for enclosed devices like hearing aids where venting isn’t possible.

Can I mix zinc and lithium batteries in the same device?

Never mix chemistries in series connections – the voltage mismatch (1.5V zinc vs 3.7V lithium) causes dangerous imbalances. In parallel configurations, the higher-voltage battery will overwork the weaker one.

However, some advanced devices use separate circuits for different battery types, like medical equipment combining lithium for memory backup and zinc for primary power. Always follow manufacturer guidelines.

How should I store unused batteries for maximum lifespan?

For lithium-ion: store at 40-60% charge in 15-25°C environments. Zinc batteries require airtight containers with desiccants to prevent electrolyte drying. Remove zinc-air battery tabs only when needed.

Pro tip: label storage dates and rotate stock – lithium loses 2-3% charge monthly, while zinc-carbon lasts 3-5 years when properly sealed. Never refrigerate batteries as condensation causes damage.

Are zinc batteries really more environmentally friendly than lithium?

Zinc batteries have advantages: they’re mercury-free since 1996 and easier to recycle (80% material recovery vs lithium’s 50%). However, their single-use nature creates more waste.

Modern lithium recycling plants can recover 95% of materials, but collection infrastructure lags. The greenest choice depends on usage – rechargeable lithium for frequent needs, zinc for occasional use where recycling is available.

What are the fire risks with lithium batteries, and how can I prevent them?

Lithium fires occur from thermal runaway – a chain reaction starting at 150°C. Prevention requires: using quality chargers with overcharge protection, avoiding physical damage, and never exposing to temperatures above 60°C.

For large lithium packs (like in EVs), install thermal sensors and Class D fire extinguishers. Zinc batteries present minimal fire risk, making them preferable for high-temperature environments.

Why are zinc-air batteries used in hearing aids instead of lithium?

Zinc-air’s stable voltage discharge curve matches hearing aid requirements perfectly, providing consistent power until complete depletion.

Their air-activated design offers high energy density (for their size) without recharge complexity. Plus, they’re safer near sensitive ear anatomy – no risk of thermal events. Newer models like the Power One Implant Plus last 7-10 days with 1.45V output throughout.